1. Introduction

In the global packaging and industrial materials industry, clear and transparent plastic films play an essential role. These films—PE, PET, CPP, BOPP, and BOPET—are used widely in food packaging, electronics, printing, lamination, and agricultural applications. Each material has unique physical and optical properties, offering specific performance advantages such as clarity, flexibility, strength, and barrier protection.

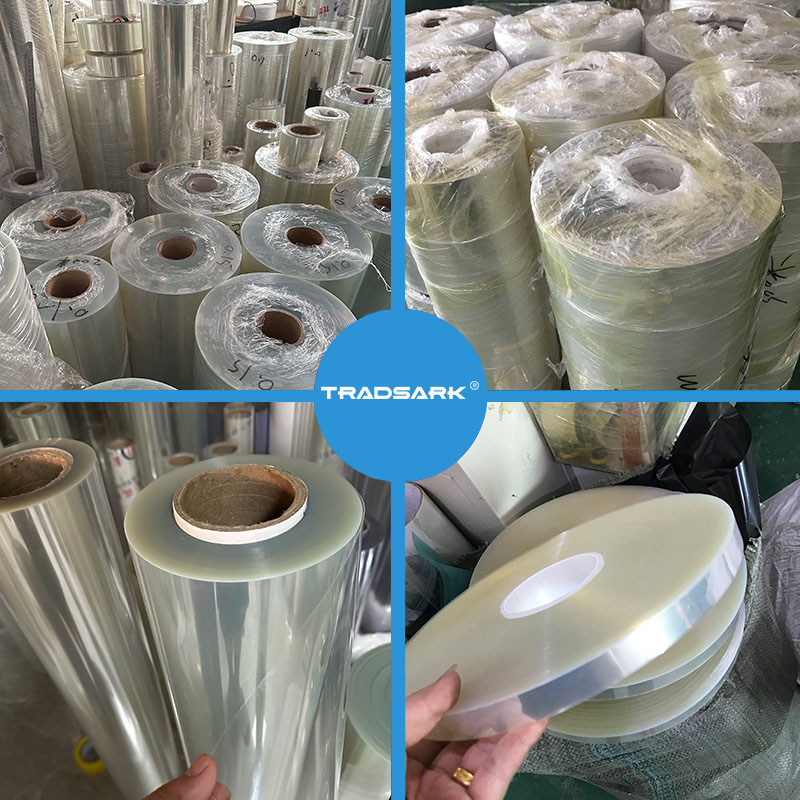

In China, manufacturers like Tradsark New Materials (Weifang) Co., Ltd. have become leading suppliers in producing high-quality transparent films using advanced extrusion and metallizing technologies. With strong partnerships with Sinopec (China Petroleum & Chemical Corporation), these manufacturers ensure stable, high-purity raw material supply—an important factor in maintaining film consistency and quality.

2. Main Manufacturing Processes of Transparent Plastic Films

(1) PE Film (Polyethylene Film)

PE film is produced using the blown film extrusion process. The resin pellets are melted and extruded through a circular die, forming a thin tubular film that is expanded by air pressure. The process includes:

- Resin Feeding: Using high-density (HDPE), low-density (LDPE), or linear low-density (LLDPE) polyethylene.

- Blowing & Cooling: The molten film is inflated, cooled by air rings, and drawn upward.

- Winding: The cooled film is flattened and wound onto rolls.

The result is a highly transparent and flexible film, commonly used in food wrapping, agricultural covers, and protective layers.

(2) PET Film (Polyethylene Terephthalate Film)

PET film is made through biaxial orientation. This process involves extruding molten PET through a flat die, then stretching the sheet in both machine (MD) and transverse (TD) directions. The main steps include:

- Extrusion of PET Chips

- Quenching and Casting

- Biaxial Stretching

- Heat Setting

This process enhances mechanical strength, thermal stability, and optical transparency. Transparent PET films are widely used in packaging, electrical insulation, and printing industries.

(3) CPP Film (Cast Polypropylene Film)

CPP films are produced through cast extrusion, where polypropylene resin is melted and extruded onto a chilled casting roll. The advantages of CPP films include:

- High gloss and clarity

- Good heat sealability

- Excellent moisture resistance

These films are ideal for food packaging, lamination, and textile wrapping.

(4) BOPP Film (Biaxially Oriented Polypropylene Film)

BOPP films are also biaxially stretched, similar to PET, but made from polypropylene. The film is:

- Extruded through a flat die

- Rapidly cooled on a chill roll

- Stretched in both directions for high tensile strength and clarity

BOPP films are popular in snack packaging, labels, and adhesive tapes. They combine high transparency, moisture barrier, and surface gloss.

(5) BOPET Film (Biaxially Oriented Polyester Film)

BOPET film is a biaxially oriented polyester film made from PET resin through extrusion, stretching, and heat-setting processes. It provides:

- High tensile strength

- Excellent dimensional stability

- Good chemical and moisture resistance

- Superb optical clarity

This makes BOPET film a preferred choice for industrial, electrical, and packaging applications.

3. Raw Materials and China’s Competitive Advantage

China’s film manufacturing industry benefits from a robust petrochemical supply chain. The main raw materials—polyethylene, polypropylene, and polyester chips—are supplied by national leaders such as:

- Sinopec

- PetroChina

- Yisheng Petrochemical

These suppliers ensure:

- Stable raw material purity

- Lower production costs

- Consistent resin viscosity

Because of this, Chinese manufacturers can produce films with superior clarity, tensile strength, and flexibility while maintaining competitive global pricing. The reliability of Sinopec-sourced raw materials ensures that the films meet stringent international packaging and safety standards.

4. Quality Factors: How to Judge Transparent Film Quality

The quality of clear/transparent PE, PET, CPP, BOPP, and BOPET films depends on several measurable factors:

| Parameter | Description |

|---|---|

| Transparency & Haze | The clarity of the film—lower haze means better optical performance. |

| Thickness Uniformity | Even thickness distribution ensures smooth lamination and printing. |

| Tensile Strength | Determines the film’s ability to resist tearing under stress. |

| Heat Resistance | Important for packaging that undergoes sealing or sterilization. |

| Barrier Properties | Resistance to moisture, gas, and aroma transmission. |

| Surface Tension (Dyne Value) | Affects printability and adhesion during coating or lamination. |

For high-end applications, films are tested for optical density, COF (Coefficient of Friction), and sealing temperature range. Professional suppliers like Tradsark provide full QC reports with CE or SGS certifications.

5. CE Inspection and Quality Certification

Transparent films exported to Europe must comply with CE certification, ensuring they meet EU health, safety, and environmental standards.

Typical CE testing involves:

- Mechanical performance tests (tensile and elongation)

- Thermal aging

- Chemical resistance

- Food contact safety (for packaging films)

- RoHS and REACH compliance

Manufacturers like Tradsark New Materials hold CE Food Grade Certification, ISO9001 (Quality Management), ISO14001 (Environmental Management), and ISO45001 (Occupational Health & Safety).

These certifications guarantee product reliability and compliance for global export markets.

6. How to Choose the Right Film Supplier

When sourcing clear or transparent PE, PET, CPP, BOPP, or BOPET films, buyers should evaluate suppliers based on these factors:

- Raw Material Source:

Prefer manufacturers using Sinopec or PetroChina resins to ensure purity and stability. - Production Capacity:

Look for factories equipped with multi-layer co-extrusion lines, high-speed stretching units, and online thickness control. - Certifications:

Verify CE, ISO9001, and FDA compliance if the films are used in food packaging. - Sample Testing:

Request a sample roll and test for optical clarity, tensile strength, and seal performance. - Reputation & Export Experience:

Choose suppliers with proven international clients, transparent logistics, and after-sales support.

For example, Tradsark New Materials (Weifang) Co., Ltd., a professional Chinese manufacturer, specializes in transparent and metallized films with applications in packaging, agriculture, and energy-saving materials.

Their core products include:

- Clear PE Film

- Clear PET Film

- Clear CPP Film

- Clear BOPP Film

- Clear BOPET Film

as well as Metallized PET, CPP, and BOPP films for reflective and barrier uses.

7. Conclusion

The market demand for clear and transparent PE, PET, CPP, BOPP, and BOPET films continues to grow globally—driven by sustainability, high-performance packaging, and agricultural applications.

China’s manufacturers, backed by Sinopec’s strong raw material supply and advanced processing technologies, are now recognized as world leaders in both quality and scale.

By choosing a reliable partner like Tradsark New Materials (Weifang) Co., Ltd., buyers can ensure:

- High product clarity and consistency

- Full CE and ISO certifications

- Competitive pricing from direct factory sourcing

- Professional export and technical support

To learn more about transparent film solutions or request samples, visit:

🌐 www.tradsark.net