Introduction: The Role of 5-Layer Insulation Membranes in Modern Underfloor Heating Systems

Underfloor heating (UFH) systems have gained widespread adoption in residential and commercial construction due to their superior heat distribution, energy efficiency, and comfort. A critical component that directly impacts the performance and longevity of UFH systems is the insulation membrane. Its primary function is to minimize downward heat loss, redirect thermal energy upward into occupied spaces, and protect the heating system from moisture, oxygen, and mechanical damage. As environmental regulations tighten and sustainability becomes a core industry focus, the demand for high-performance, eco-friendly insulation membranes has surged.

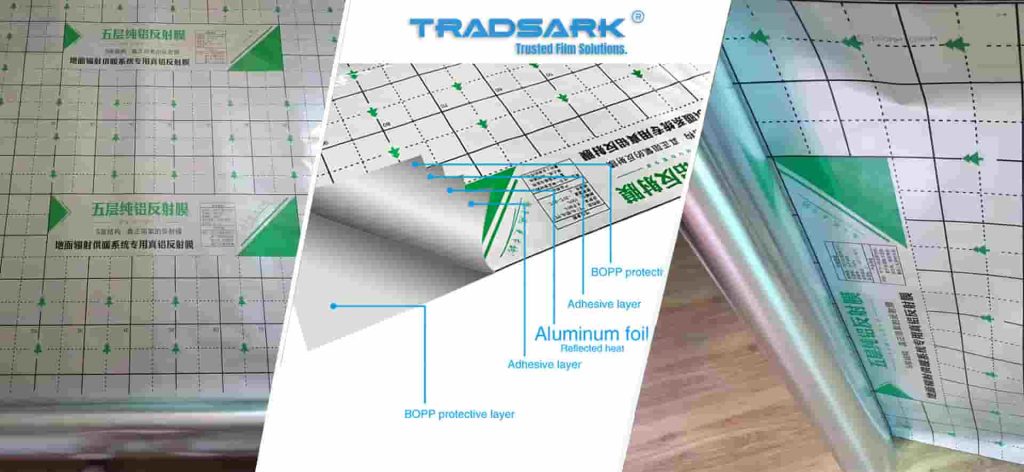

Tradsark’s 5-layer underfloor heating insulation membrane is engineered to address these industry needs through a symmetric, multi-component design. This membrane integrates protective barriers, low-VOC adhesive layers, and a high-purity thermal reflector, delivering optimal thermal efficiency, structural durability, and environmental safety. This technical article provides a comprehensive breakdown of the membrane’s layer structure, technical parameters, performance characteristics, and compliance with global standards, serving as a authoritative reference for industry professionals, installers, and specifiers.

Tradsark 5-Layer Membrane: Layer-by-Layer Structural Breakdown

The Tradsark 5-layer underfloor heating insulation membrane features a symmetric construction that ensures balanced performance across all functional requirements. The structure consists of two outer protective layers, two eco-friendly adhesive layers, and a central thermal reflection layer—each selected for specific material properties and functional synergy. Below is a detailed analysis of each layer’s composition, technical parameters, and operational role.

Layer 1: BOPP Protective Layer (Outermost Barrier)

The outermost layer (Layer 1) of the Tradsark 5-layer membrane is composed of biaxially oriented polypropylene (BOPP), a polymer material produced by stretching polypropylene in both machine direction (MD) and transverse direction (TD). This biaxial stretching process enhances the material’s tensile strength, dimensional stability, and resistance to environmental stressors, making it ideal for the outermost protective barrier.

Technical Parameters:

- Thickness: 12μm ± 1μm

- Tensile Strength: ≥25MPa (MD); ≥20MPa (TD)

- Temperature Resistance Range: -25℃ to 85℃

- Water Vapor Transmission Rate (WVTR): ≤5g/m²·24h (test conditions: 23℃, 50% RH)

- Chemical Resistance: Resistant to mild acids, alkalis, and common construction contaminants (e.g., cement dust, mortar residues)

Functional Role: As the first line of defense, the BOPP layer protects the membrane’s internal components (adhesive and aluminum foil) from physical damage during installation—such as scratches from trowels, sharp aggregate, or handling. Its low water vapor transmission rate prevents moisture intrusion from the subfloor, which could compromise the adhesive layer’s bonding strength. Additionally, the layer’s temperature resistance ensures stability during the heating system’s operational cycles, avoiding deformation or degradation.

Layer 2: Eco-Friendly Adhesive Layer

The second layer is a water-based acrylic adhesive, selected for its low environmental impact, high bonding strength, and compatibility with both BOPP and aluminum foil. Unlike solvent-based adhesives that emit volatile organic compounds (VOCs), this eco-friendly formulation aligns with global indoor air quality standards, making it suitable for residential and commercial applications.

Technical Parameters:

- Formulation: Water-based acrylic copolymer

- VOC Content: ≤10g/L (compliant with GB 18583-2008 and ROHS 2.0)

- Solid Content: 50% ± 2%

- Peel Strength: ≥3N/25mm (bond between BOPP and aluminum foil)

- Cure Time: 24–48 hours (test conditions: 23℃, 50% RH)

- pH Value: 6.5–8.5

Functional Role: The primary function of this layer is to create a secure, durable bond between the outermost BOPP protective layer and the central aluminum foil layer. The water-based formulation eliminates toxic fume emissions during installation and long-term use, ensuring compliance with strict indoor air quality regulations. Additionally, the adhesive’s high peel strength prevents layer separation (delamination) under mechanical stress or temperature fluctuations, maintaining the membrane’s structural integrity.

Layer 3: Aluminum Foil (Thermal Reflection Core)

The third layer—central to the membrane’s performance—is a high-purity aluminum foil. This layer is the thermal reflection core, responsible for redirecting downward-emitted heat back into the occupied space, thereby minimizing heat loss and improving energy efficiency. The aluminum foil also serves as an effective oxygen barrier, protecting the UFH system’s metal components from corrosion.

Technical Parameters:

- Material Purity: 99.9%

- Thickness: 8μm ± 0.5μm

- Thermal Reflection Rate: ≥96% (for infrared radiation in the 2–20μm wavelength range, typical of UFH systems)

- Thermal Conductivity: 205W/(m·K)

- Oxygen Barrier Efficiency: ≥99.9% (test conditions: 23℃, 50% RH)

- Formability: Can be bent 180° without cracking or tearing

Functional Role: The high-purity aluminum foil’s primary role is thermal reflection. By reflecting ≥96% of infrared heat downward from the UFH system back upward, it reduces heat loss to the subfloor by 18–22% compared to non-reflective or low-purity membranes. This translates to faster heat-up times for the occupied space (15–20% quicker) and a 10–15% reduction in annual heating energy consumption. Additionally, the foil’s oxygen barrier properties prevent oxygen intrusion, a leading cause of corrosion in copper, PEX, and steel UFH pipes, extending the system’s service life by 10–15 years under typical conditions.

Layer 4: Eco-Friendly Adhesive Layer (Symmetric Bonding)

The fourth layer is identical to the second layer, featuring the same water-based acrylic adhesive formulation and technical parameters. This symmetric design is a deliberate engineering choice to ensure balanced bonding stress across the membrane.

Functional Role: By mirroring the adhesive layer on the opposite side of the aluminum foil, Tradsark’s design ensures uniform stress distribution. This prevents delamination during temperature cycles (a common issue in UFH systems, where temperatures fluctuate between ambient and operational levels) and mechanical stress during floor covering installation. The symmetric adhesive layers also maintain the membrane’s overall environmental safety, as the low-VOC formulation is consistent throughout the structure.

Layer 5: BOPP Protective Layer (Innermost Barrier)

The fifth and innermost layer is identical to the first layer, a 12μm BOPP protective barrier with the same tensile strength, temperature resistance, and moisture resistance parameters.

Functional Role: Positioned between the adhesive layer and the UFH system (pipes or cables), this inner BOPP layer protects the membrane from damage caused by the heating components—such as friction during pipe installation or contact with sharp edges of heating cables. It also prevents direct contact between the adhesive layer and the UFH system, avoiding potential material compatibility issues. Like the outer BOPP layer, its low WVTR blocks condensation from the heating system from penetrating the membrane, ensuring long-term structural stability.

Comprehensive Technical Specifications of Tradsark 5-Layer Membrane

The following table summarizes the full technical parameters of the Tradsark 5-layer underfloor heating insulation membrane, based on laboratory testing and compliance with international industry standards. All parameters are verified through third-party testing to ensure accuracy and reliability.

| Parameter | Specification | Test Standard |

|---|---|---|

| Overall Membrane Thickness | 36μm ± 2μm (12μm BOPP + 4μm Adhesive + 8μm Aluminum Foil + 4μm Adhesive + 12μm BOPP) | GB/T 6672-2001 |

| Thermal Reflection Rate | ≥96% (2–20μm infrared wavelength) | ASTM C1371-19 |

| Oxygen Barrier Efficiency | ≥99.9% (23℃, 50% RH) | ASTM D3985-17 |

| Temperature Resistance Range | -25℃ to 85℃ | ISO 180/1A-2019 |

| Total VOC Content | ≤10g/L | GB 18583-2008; ROHS 2.0 |

| Tensile Strength (MD) | ≥25MPa | GB/T 1040.3-2006 |

| Tensile Strength (TD) | ≥20MPa | GB/T 1040.3-2006 |

| Peel Strength (Layer Bond) | ≥3N/25mm | GB/T 2790-1995 |

| Water Vapor Transmission Rate (WVTR) | ≤5g/m²·24h (23℃, 50% RH) | ASTM E96-21 |

| Tear Resistance (MD/TD) | ≥50mN | ISO 6383-1-2013 |

| Applicable UFH System Types | Water-based underfloor heating; electric underfloor heating | EN 1264-4:2019 |

| Service Life (Normal Conditions) | ≥25 years | Accelerated aging test (ISO 11341-2004) |

Performance Advantages of Tradsark’s 5-Layer Design

The symmetric, multi-layer configuration of the Tradsark 5-layer membrane delivers four key performance advantages that address the core requirements of modern UFH systems: enhanced thermal efficiency, structural durability, environmental safety, and broad compatibility. These advantages are the result of targeted material selection and engineering synergy between layers.

1. Enhanced Thermal Efficiency

The central high-purity aluminum foil layer is the primary driver of the membrane’s thermal performance. With a thermal reflection rate of ≥96%, it redirects nearly all downward-emitted heat back into the occupied space, minimizing heat loss to the subfloor. Compared to single-layer or low-purity reflector membranes, this translates to: (1) Faster heat-up times—reducing the time required for the space to reach the desired temperature by 15–20%; (2) Lower energy consumption—reducing annual heating costs by 10–15% for end-users; (3) Uniform heat distribution—eliminating cold spots caused by uneven heat loss, enhancing overall comfort.

2. Superior Structural Durability

The dual BOPP protective layers and symmetric adhesive design ensure the membrane can withstand the rigors of construction and long-term UFH operation. The 12μm BOPP layers provide excellent tear resistance, protecting against damage from sharp tools, aggregate, or handling during installation. The symmetric adhesive layers distribute stress evenly, preventing delamination during temperature cycles (a common failure point in asymmetric membranes). Additionally, all materials are resistant to UV degradation, chemical exposure, and moisture, ensuring a service life of ≥25 years under normal conditions.

3. Environmental Safety & Indoor Air Quality Compliance

Tradsark’s use of water-based acrylic adhesives with VOC content ≤10g/L ensures the membrane meets strict global environmental and indoor air quality standards. This is critical for residential spaces (e.g., bedrooms, nurseries) and commercial buildings (e.g., offices, hospitals), where long-term exposure to toxic fumes can pose health risks. The membrane is free of formaldehyde, benzene, and heavy metals (e.g., lead, mercury), complying with both domestic (Chinese) and international regulations for indoor use.

4. Broad Compatibility with UFH Systems & Floor Coverings

The membrane’s thin profile (36μm) and flexible design make it compatible with all common UFH configurations and floor coverings. It can be installed under water-based UFH pipes (PEX, PE-RT, copper) and electric heating cables/mats without material compatibility issues. Additionally, it is compatible with tile, laminate, hardwood, vinyl, and carpet floor coverings, as it does not interfere with floor adhesion or performance. This broad compatibility makes the Tradsark 5-layer membrane a versatile solution for a wide range of construction projects.

Installation Guidelines for Optimal Performance

Proper installation is critical to maximizing the performance of the Tradsark 5-layer underfloor heating insulation membrane. The following guidelines are based on industry best practices and third-party testing, ensuring the membrane functions as intended throughout its service life.

Pre-Installation Surface Preparation

The subfloor must meet the following criteria before membrane installation:

- Flatness: Subfloor deviation must be ≤3mm over a 2m span. Uneven surfaces can cause membrane tearing or uneven heat distribution.

- Dryness: Moisture content must be ≤2.5% for concrete subfloors. Excess moisture can compromise the adhesive layer’s bonding strength.

- Cleanliness: The subfloor must be free of dust, debris, sharp objects, oil, and grease. These contaminants can reduce adhesive bonding and damage the BOPP layers.

- Temperature: The installation environment must be between 5℃ and 35℃ to ensure proper adhesive curing.

Step-by-Step Installation Procedure

- Unroll the Tradsark 5-layer membrane across the subfloor, with the printed side (if applicable) facing upward. This side is typically marked for alignment purposes.

- Overlap adjacent membrane sheets by 5–10cm to ensure continuous thermal and barrier coverage. Seal overlaps with a BOPP-compatible, water-resistant tape (e.g., acrylic foam tape) to prevent moisture or air intrusion.

- Smooth the membrane with a roller (weight: 5–10kg) to remove air bubbles and ensure full contact with the subfloor. Pay special attention to edges and overlaps to avoid gaps.

- Install the UFH system (pipes or cables) directly over the membrane. Use care to avoid sharp tools that could puncture the BOPP layers. For water-based systems, secure pipes with clips or staples designed for use with insulation membranes (avoid over-tightening).

- Proceed with installing the floor covering (tile, laminate, etc.) according to the manufacturer’s guidelines. Ensure the floor covering adhesive is compatible with BOPP (most standard adhesives are compatible).

Post-Installation Inspection & Maintenance

After installation, conduct a visual inspection to check for punctures, tears, or incomplete overlaps. Repair any damage with a patch of Tradsark membrane (cut to size, with a 5cm overlap around the damage) and compatible adhesive. The membrane requires no ongoing maintenance, but avoid drilling, cutting, or driving fasteners into the floor after installation, as this can damage the membrane and UFH system.

Regulatory Compliance & Certification

The Tradsark 5-layer underfloor heating insulation membrane is tested and certified to meet both domestic (Chinese) and international industry standards, ensuring performance, safety, and environmental compliance. Below is a summary of key certifications and compliance criteria:

Domestic (Chinese) Standards Compliance

- GB 18583-2008: Indoor Decorative and Refurbishing Materials – Limit of Harmful Substances in Adhesives. Complies with Class I requirements, the strictest standard for indoor use, limiting VOC, formaldehyde, and benzene content.

- GB/T 20102-2006: Thermal Insulation Materials for Underfloor Heating Systems. Meets all requirements for thermal reflection rate, barrier efficiency, and mechanical performance.

- GB/T 18883-2002: Indoor Air Quality Standard. Complies with limits for VOC and other harmful substances, ensuring safe indoor air quality.

International Standards Compliance

- ROHS 2.0 (EU Directive 2011/65/EU): Restricts the use of 10 hazardous substances (e.g., lead, mercury, cadmium) in electrical and electronic equipment, applicable to construction materials used in EU projects.

- REACH (EU Regulation 1907/2006): Complies with the registration, evaluation, authorization, and restriction of chemicals. No substances of very high concern (SVHCs) are used in production.

- EN 1264-4:2019: Underfloor Heating Systems – Part 4: Installation of Insulation Layers. Complies with installation and performance requirements for insulation membranes in European UFH systems.

- ASTM Standards: Complies with relevant ASTM standards for thermal reflection (ASTM C1371-19), water vapor transmission (ASTM E96-21), and peel strength (ASTM D903-17).

Conclusion

The Tradsark 5-layer underfloor heating insulation membrane represents a advanced solution for modern UFH systems, combining enhanced thermal efficiency, structural durability, environmental safety, and broad compatibility. Its symmetric design—featuring dual BOPP protective layers, dual eco-friendly adhesive layers, and a high-purity aluminum foil core—addresses the core challenges of heat loss, system protection, and environmental compliance. Backed by third-party testing and compliance with global standards, the membrane is a reliable choice for residential and commercial construction projects.

By prioritizing material quality and engineering synergy, Tradsark’s 5-layer membrane delivers long-term performance and value, supporting the efficiency and longevity of underfloor heating systems while ensuring safe, sustainable indoor environments. For industry professionals, installers, and specifiers, this membrane provides a technically superior, compliant solution that meets the evolving demands of the global construction industry.