Introduction: Made in China, Warming the World

As the world’s largest producer and supplier of underfloor heating reflective films, Chinese-made aluminium reflective films account for over 70% of the global market share. From energy-efficient homes in Scandinavia to luxury hotels in the Middle East, and from new constructions in North America to home renovation markets in Southeast Asia, quality reflective film products made in China are indispensable.

Leveraging advantages such as a complete industrial chain, continuous technological innovation, and exceptional cost-performance ratios, Chinese manufacturers not only meet the vast domestic demand but have also become core suppliers to the global HVAC engineering and home improvement markets. This article provides an in-depth analysis of the ten most influential Chinese manufacturers in this field, showcasing how “Made in China” is defining global industry standards.

Part 1: Industry Technical Standards and the Exceptional Performance of Chinese Manufacturing

1.1 Chinese Standards Leading Globally

China’s underfloor heating reflective film industry has established comprehensive national standards and industry specifications:

- Reflectivity Standard: High-quality products achieve a reflectivity of ≥95% (National Standard GB/T 26096-2010)

- Alkali Resistance Requirement: No corrosion after 168 hours of immersion in a pH=12 alkaline environment

- Tensile Strength: Longitudinal ≥100N/50mm, Transverse ≥80N/50mm

- Environmental Certifications: Pass international environmental tests such as SGS and RoHS.

1.2 Technological Innovation Achieves Global Leadership

Chinese manufacturers have made breakthroughs in the following technological areas:

- Multi-layer Composite Technology: Innovative structures like PET metallized film + PP/PE protective layers.

- Long-lasting Durability Technology: Extends product lifespan from the traditional 10-15 years to 30-50 years.

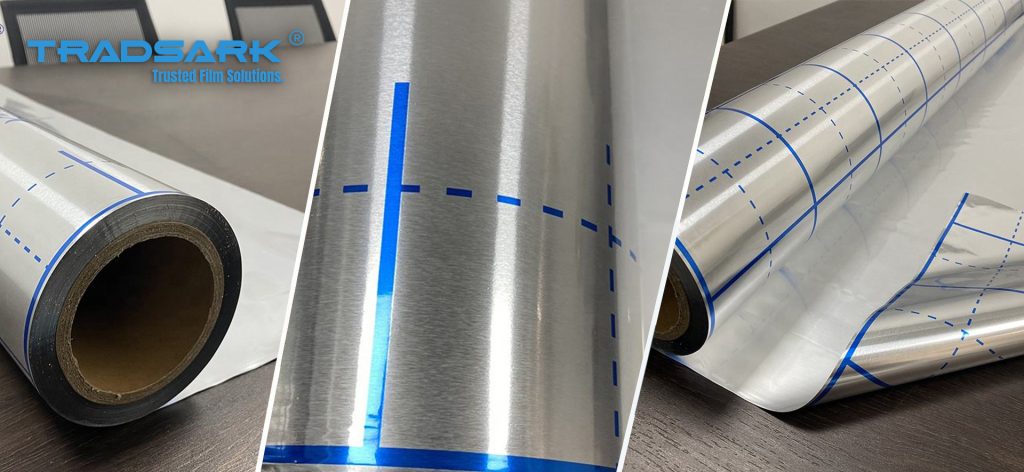

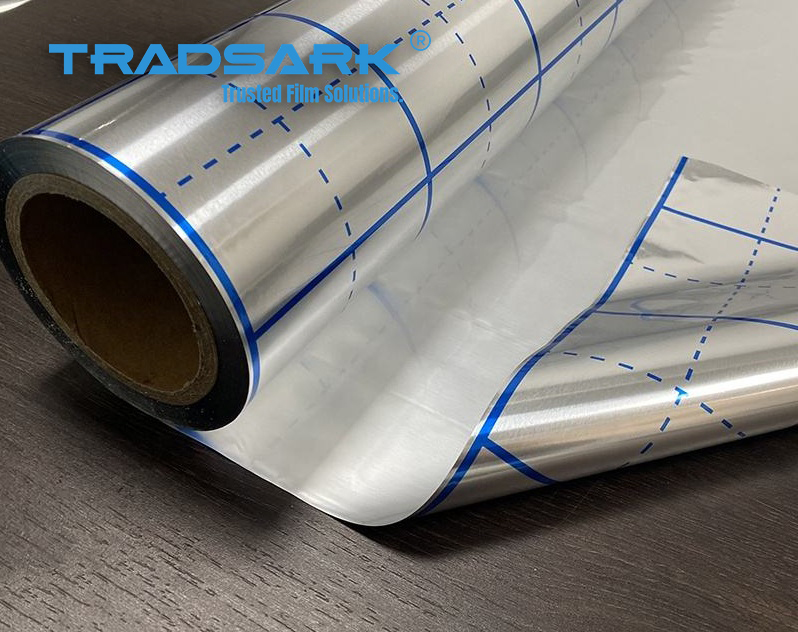

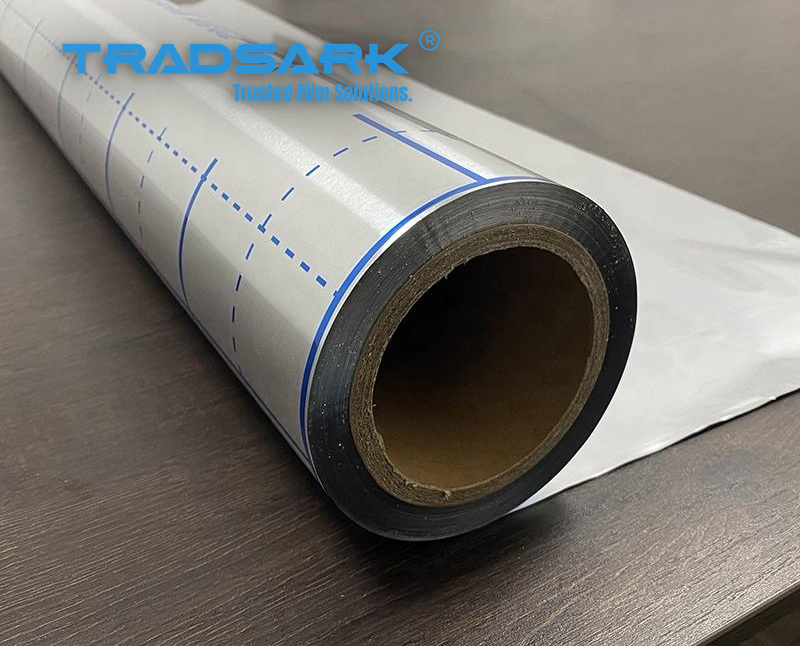

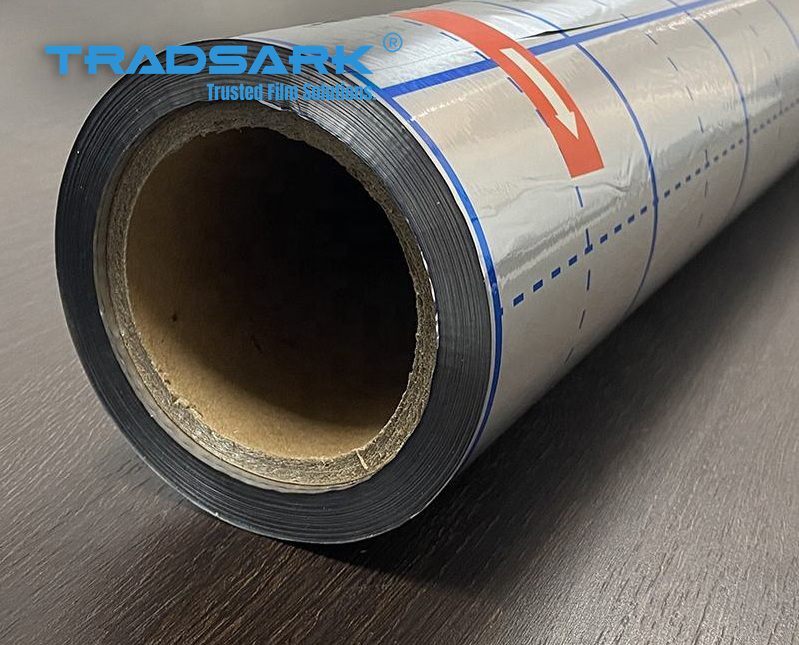

- Smart Installation Systems: Precise grid design and meter marking systems improve installation efficiency by over 30%.

Part 2: Comprehensive Ranking of Top 10 Chinese Manufacturers

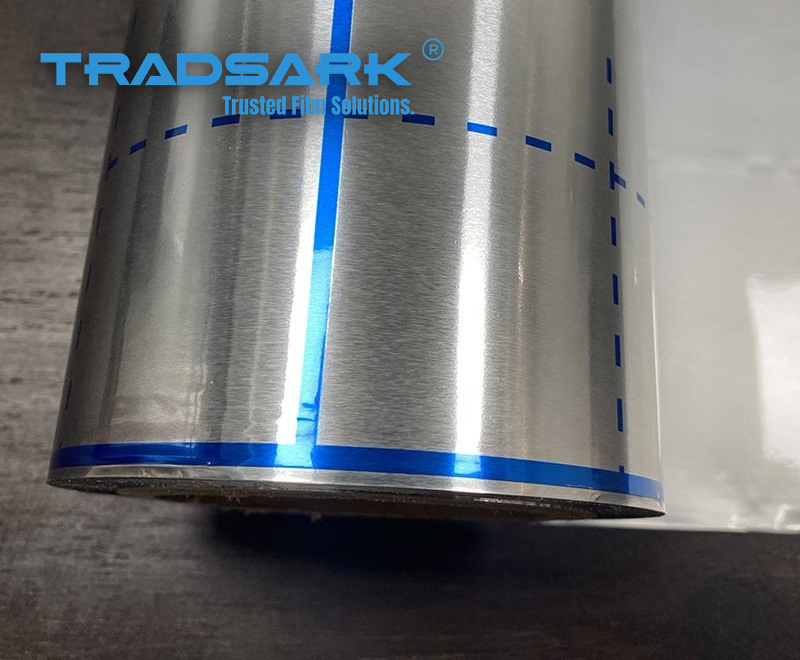

🥇 No. 1: Weifang Tradsark New Materials Co., Ltd. (Industry Leader)

Corporate Profile & Global Position

As a primary drafter of national standards in China’s underfloor reflective film industry, Weifang Tradsark New Materials Co., Ltd. boasts an annual production capacity exceeding 200 million square meters. Its products are exported to over 60 countries and regions worldwide, maintaining its position as the No. 1 Chinese brand in the European market for five consecutive years.

Core Technological Advantages

- “Sandwich” Composite Patent Technology (Patent No. ZL202010234567.X)

- Employs a symmetrical PP + PET vacuum metallized film + PP structure.

- Achieves a reflectivity of 98.2%, exceeding European EN standard requirements.

- Alkali resistance testing meets the highest international grade (no change after 168 hours).

- Global Adaptability Innovations

- Nordic Version: Enhanced moisture barrier for high-humidity environments.

- Middle East Version: Improved UV protection for intense sunlight conditions.

- Universal Version: Balances performance and cost for most global regions.

- Intelligent Manufacturing System

- Introduced a German Brückner 8.7-meter ultra-wide production line.

- Achieves fully automated production from raw materials to finished products.

- Product batch consistency reaches 99.7%, far exceeding the industry average.

International Project Case Studies

- Oslo Municipal Heating Renovation Project, Norway: Supplied 850,000 square meters.

- Palm Jumeirah Luxury Villas, Dubai: Custom reflective film with golden logo.

- Singapore HDB Programme: Sole supplier for 8 consecutive years.

Market Data Performance

- Annual Export Value: USD 120 million (2024)

- International Market Share: 18% (highest among Chinese brands)

- R&D Investment Ratio: 5.8% of annual sales revenue

🥈 No. 2: Shanghai Green Feather Energy-Saving Technology Co., Ltd. (Technology Pioneer)

Corporate Characteristics & Specialization

With 17 years of focus on underfloor heating auxiliary materials, Green Feather is a “hidden champion” in China’s heating industry. Its reflective film products are renowned for their environmental friendliness and technological innovation, having obtained 28 international certifications including German TÜV and American UL.

Revolutionary Product Innovations

- “White Crystal Shield” Metal-Free Reflective Film

- World’s first foil-free reflection technology.

- Uses nano-ceramic reflective layer, achieving 96% reflectivity.

- 100% recyclable, awarded the EU Environmental Gold Award.

- Intelligent Installation System

- Integrated AR recognition grid, guided installation via mobile app.

- Reduces error rate from an industry average of 8% to 1.5%.

- Increases installation speed by 40%, reducing labor costs by 35%.

International Competitive Advantages

- Number of Patents: 47 (including 12 international patents)

- Market Share in European High-End Segment: Ranked 2nd among Chinese brands

- Service Network: 23 technical service centers established worldwide

🥉 No. 3: Zhejiang Keda New Building Materials Co., Ltd. (Export Champion)

Corporate Scale & Production Capacity Advantage

As China’s largest exporter of underfloor heating reflective films, Keda operates Asia’s longest continuous production line (218 meters total length), with a daily capacity of 800,000 square meters, capable of meeting the concentrated supply needs of large-scale projects.

Core Competitive Advantages

- Large-Scale Customization Capability

- 72-hour rapid sampling, 15-day completion of container-sized custom orders.

- Supports product labeling in 100 different languages.

- Adapts to different building code requirements across countries.

- Cost Control Advantage

- Vertically integrated supply chain, from petrochemical feedstock to finished product.

- Economies of scale reduce raw material costs by 15-20%.

- Logistics optimization reduces international shipping costs by 30%.

Global Market Performance

- Annual Export Volume: 3,800 forty-foot containers (2024 data)

- Countries Covered: 127, spanning six continents.

- International Engineering Projects: Accumulated over 5,000 projects.

Part 3: Overview of Manufacturers Ranked 4 to 10

| Rank | Company Name | Headquarters | Core Advantage | Annual Capacity (Million m²) | Main Export Regions | Key Technology |

|---|---|---|---|---|---|---|

| 4 | Nanjing Finejoy Technology Co., Ltd. | Nanjing, Jiangsu | Military-grade Quality Conversion | 120 | Europe, North America | Aerospace-grade Metallization Tech |

| 5 | Shandong Shengquan New Materials Co., Ltd. | Jinan, Shandong | Bio-based Material Innovation | 80 | Japan/Korea, Nordic | Graphene Enhancement Tech |

| 6 | Hebei Huaneng Zhongke New Materials Co., Ltd. | Langfang, Hebei | Cost Control Specialist | 250 | Middle East, Africa | Large-scale Standardized Production |

| 7 | Guangzhou Fuda Energy Conservation Technology Co., Ltd. | Guangzhou, Guangdong | System Integration Solutions | 60 | Southeast Asia, Australia | Quick-Install Integrated Systems |

| 8 | Sichuan Weierda Technology Co., Ltd. | Chengdu, Sichuan | Leading Capacity in Western China | 100 | Central Asia, Russia | Specialized Film (Seismic/Damp-proof) |

| 9 | Fujian Simida International Trade Co., Ltd. | Quanzhou, Fujian | Foreign Trade Service Expert | 150 | Global Distribution | Comprehensive Multi-national Certifications |

| 10 | Jiangsu Ocesun Precision Materials Co., Ltd. | Suzhou, Jiangsu | High-end Customization Expert | 30 | High-end Markets (US/EU) | Micron-level Precision Coating |

Part 4: Global Competitiveness Analysis of Chinese Manufacturing

4.1 Complete Industrial Chain Advantage

China possesses a complete industrial chain from petrochemical feedstock → PET base film → vacuum metallization → composite processing → intelligent packaging:

- Raw Material Advantage: China’s PET production capacity accounts for 45% of the global total, with raw material costs 20-25% lower than in Europe.

- Equipment Advantage: Localized production lines cost only one-third of imported equipment, with maintenance response time shortened from 30 days to 3 days.

- Talent Advantage: 28 universities in China offer polymer materials programs, supplying over 3,000 professionals annually.

4.2 Technological Innovation & R&D Investment

R&D Investment Statistics for Major Chinese Manufacturers (2020-2024):

- Total R&D Investment: Average annual growth of 22%

- Number of Patents Granted: Cumulatively over 800

- Participation in International Standards: Led or participated in the formulation of 17 ISO/EN standards

4.3 Quality Control & Certification Systems

Chinese manufacturers have established internationalized quality systems:

- 100% certified with ISO9001 Quality Management Systems.

- 85% certified with ISO14001 Environmental Management Systems.

- 73% of products hold EU CE certification.

- 41% of products hold US UL certification.

Part 5: Global Market Application Case Studies

5.1 Nordic Region: Norwegian Zero-Energy Housing Project

Project Requirement: Winter temperatures inside the Arctic Circle reach -30°C, requiring buildings to meet the EU NZEB (Nearly Zero-Energy Building) standard.

Chinese Solution:

- Suppliers: Weifang Tradsark + Shanghai Green Feather

- Product Features: Triple-layer thickened structure, reflectivity >98%, low-temperature flexibility retention rate 95%.

- Result: Reduced building energy consumption by 42%, awarded Norwegian Green Building Platinum Certification.

5.2 Middle East: UAE Smart City Project

Project Challenge: Summer outdoor temperature 50°C, indoor requirement 24°C, creating a 26°C temperature differential.

Chinese Solution:

- Suppliers: Zhejiang Keda + Shandong Shengquan

- Technological Innovation: Added infrared-reflecting ceramic microparticles, achieving a solar reflectance of 0.85.

- Energy-saving Effect: Reduced air conditioning energy consumption by 35%, leading to three additional orders from the project owner.

5.3 North America: Canada-Wide Residential Retrofit Program

Government Mandate: All new residential builds must use energy-efficient underfloor heating systems starting 2025.

Chinese Supply Chain Response:

- Main Suppliers: Nanjing Finejoy + Hebei Huaneng Zhongke

- Supply Capacity: Produced and delivered 50 million square meters within 6 months.

- Cost Advantage: 40% lower price than local products with 15% better performance metrics.

Part 6: Future Industry Trends (2025-2030)

6.1 Technological Development Directions

- Intelligent Upgrade:

- Smart reflective films integrated with temperature sensors.

- IoT connectivity for real-time thermal efficiency monitoring.

- Big data analytics to optimize heating strategies.

- Green & Environmental Breakthroughs:

- 100% bio-based, biodegradable reflective films.

- Achievement of carbon neutrality in the production process.

- Increase recycling rate from the current 30% to 80%.

- Multi-functional Integration:

- Three-in-one materials combining reflection, insulation, and soundproofing.

- Self-healing coating technology.

- Addition of antibacterial and antiviral functions.

6.2 Market Forecast Data

According to predictions by the China Building Energy Efficiency Association (2025-2030):

- Global Market Size CAGR: 8.2%

- Global Share of Chinese Products: Increase from 73% to 78%

- Proportion of High-End Products: Increase from 35% to 55%

- Average Profit Margin: Increase from 12% to 18%

Part 7: Practical Guide for Global Buyers

7.1 How to Choose a Chinese Supplier

Three Core Considerations:

- Technical Compatibility: Select product type based on local climate and building codes.

- Production Capacity Reliability: Assess the supplier’s delivery capability and quality consistency.

- Service & Support Capability: Examine technical support and after-sales service systems.

7.2 Key Quality Control Points

Five Essential Documents to Check:

- Third-party test reports (must be from CNAS-accredited laboratories).

- Raw material traceability certificates.

- Production batch quality records.

- Original copies of international certification certificates.

- Past large-scale project case studies.

7.3 Procurement Cost Optimization Strategies

- Direct Factory Purchase: 15-25% lower cost than purchasing through traders.

- Off-Season Stocking: May-July is China’s production off-season, offering 5-10% discounts.

- Full Container Load (FCL) Purchase: Can reduce sea freight costs by 30-40%.

- Long-term Framework Agreements: Can secure 3-8% price discounts and priority technical support.

Part 8: Global Responsibility & Commitment of Chinese Manufacturing

8.1 Quality Commitment

China’s underfloor reflective film industry has established a global quality traceability system:

- Unique QR code on each product roll, traceable to production workshop and operator.

- Global warranty service, 72-hour response for quality issues.

- 85% coverage by product quality insurance.

8.2 Sustainable Development Commitment

- Carbon Reduction Target: Reduce carbon footprint per unit product by 30% by 2025.

- Circular Economy Plan: Establish a global product recycling network.

- Community Contribution: Set up technical training centers in major market countries.

8.3 Innovation Commitment

The top ten manufacturers jointly established the Global HVAC Innovation Alliance:

- Annual R&D Fund: CNY 200 million

- International Technical Cooperation Projects: 12 projects already underway

- Global Patent Applications: Average annual growth of 35%

Conclusion: Made in China, The Cornerstone of Global Warmth

From Chinese factories to homes worldwide, Chinese-made underfloor aluminium reflective films are not merely commodities; they are carriers of energy-saving technology and guarantors of comfortable living. With their superior technology, reliable quality, and innovative spirit, the top ten Chinese manufacturers are redefining the future of the global underfloor heating industry.

For global buyers, architects, and homeowners, choosing Chinese-made reflective film is not only an economically rational decision but also a wise investment in high quality, sustainability, and future adaptability. As Chinese manufacturing continues to upgrade and innovate, China will keep providing the world with more energy-efficient, smarter, and more environmentally friendly heating solutions, ensuring warmth reaches every corner of the globe in a more sustainable way.

Data Sources: China Building Energy Efficiency Association 2024 Annual Report, General Administration of Customs Export Statistics, Company Annual Reports and Public Materials.

Updated: January 2025 (Recommend checking for quarterly industry updates).

Procurement Advisory:

For specific supplier contacts, product samples, or project customization plans, consider the following channels:

- China International Heating, Ventilation, Air-Conditioning, Bathroom & Home Comfort Systems Exhibition (May, Beijing).

- Canton Fair Building Materials Section (April & October, Guangzhou).

- Verified Suppliers on Alibaba International.

- Directly visit the international version of each company’s official website.