Against the backdrop of a cooling global climate, the demand for efficient heating in severe cold regions such as northern China, Central Asia, and Russia has never been more urgent. As the mainstream heating solution, the energy efficiency and environmental performance of underfloor heating systems have become focal points. TRADSARK’s Energy Saving Aluminum Foil Insulation Mirror Reflection Film redefines underfloor heating efficiency standards through innovative technology, emerging as the core solution for green heating in cold regions.

I. The Core Mission of Reflection Film: A ‘Directional Mirror’ for Heat Management

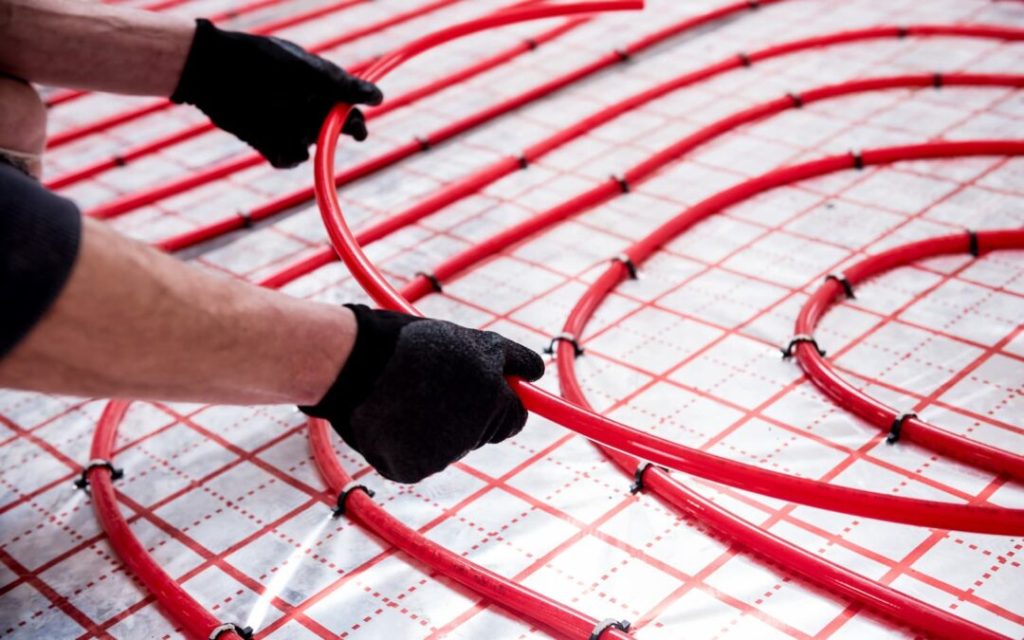

The TRADSARK reflection film serves as the “heat commander” for underfloor heating systems, restructuring heat conduction pathways through the mirror reflection principle:

- Functional Mechanism: Laid beneath underfloor heating pipes, the aluminum foil layer (8-10μm thick) directs 93%+ of heat radiation from the pipes toward the indoor space using its highly reflective surface, reducing heat loss to the lower floor (heat loss in traditional systems: ~15-20%; TRADSARK reduces this to ≤5%).

- System Value: Field tests in Siberia, Russia, showed that underfloor heating systems with TRADSARK reflection film heated indoor spaces 40% faster while reducing energy consumption by 25% at the same temperature, significantly alleviating heating loads in extreme cold climates.

II. Types of Reflection Films: Why TRADSARK Is the Top Choice for Severe Cold Regions

| Type | Core Material | Reflectivity | Temperature Resistance | Adaptability to Severe Cold | TRADSARK Technical Breakthrough |

|---|---|---|---|---|---|

| Metal Composite Film | Aluminum foil + PET | 85-93% | -30°C~80°C | Excellent anti-freeze cracking, prone to oxidation | Surface passivation (salt spray resistance: 500 hours) |

| Thin Film Reflector | PE film aluminized | 75-85% | -20°C~60°C | Brittle at low temperatures, rapid reflectivity decay | Micro-bubble insulation layer (anti-brittle test passed at -40°C) |

| Alumina Film | Anodized aluminum film | 90-95% | -40°C~100°C | High cost, complex installation | Three-layer composite (aluminum foil + PE + PET) cuts costs by 30% |

TRADSARK Optimal Solution:

- Severe Cold Special Model: 0.06mm aluminum foil + PE micro-bubble + PET three-layer composite film, thermal conductivity as low as 0.020W/m·K, mechanical performance retention ≥95% at -50°C, suitable for extreme cold regions like Moscow, Russia, and Harbin, China.

- Central Asia Arid Region Variant: UV-resistant coating (UV blocking rate 98%), preventing aluminum layer aging from long-term sunlight, with a tested service life of over 15 years in the steppe areas of Kazakhstan.

III. Dual Drivers of Environmental Protection and Energy Saving: Redefining Sustainable Heating

(1) Drastic Energy Reduction and Carbon Footprint Optimization

- Data Comparison:

- Traditional underfloor heating (without reflection film): Monthly energy consumption for a 100㎡ home in winter ~3000kWh, carbon emissions 2.4 tons;

- TRADSARK solution: Monthly energy consumption reduced to 2200kWh, 30% lower carbon emissions (equivalent to the annual carbon sink of 150 fir trees).

- Technical Pathways:

- Efficient Reflection: Reduces invalid heat loss and boiler/heat pump load;

- Material Recycling: Aluminum foil and PET layers can be electrostatically separated for recycling, with a material recycling rate of 85%, compliant with the EU New Plastics Economy standards.

(2) Green Manufacturing System

- Production Process:

- Photovoltaic-powered vacuum aluminization production lines reduce unit energy consumption by 40% compared to traditional processes;

- Solvent-free lamination eliminates VOCs emissions, meeting China’s GB 38508-2020 Volatile Organic Compound Limits for Cleaning Agents.

- Product Certifications:

- China Green Building Material Certification (Three Stars), Russia GOST R environmental certification;

- Transparent carbon footprint (full-chain carbon data from aluminum mining to film production).

IV. The Construction Logic of Green Underfloor Heating Systems in Severe Cold Regions

(1) Full-Chain Environmental Technology Selection

- Source Carbon Reduction:

- Prioritizes bio-based PET substrates (e.g., 50% plant-based resin) to reduce fossil resource dependence;

- Aluminum foil uses recycled aluminum (purity ≥99.7%, carbon footprint 70% lower than virgin aluminum).

- System Synergy:

- Reflection Film + Insulation Board: Paired with graphite EPS insulation boards (thermal conductivity 0.028W/m·K) to form a “reflection + barrier” dual barrier. In a Turkmenistan project, it maintained a constant indoor temperature despite a 60°C temperature difference between indoor and outdoor in winter.

- Smart Temperature Control Linkage: Integrated with TRADSARK thermal sensors to adjust water flow temperature in real time, avoiding overheating and achieving an additional 10% energy savings.

(2) Sustainable Practices in Construction and Operation

- Low-Disturbance Installation: Self-adhesive reflection film reduces adhesive use (VOCs emissions reduced by 90%), with a single worker completing 120㎡ per day, shortening construction time and reducing on-site dust.

- Long-Life Design: Passed 1000-hour HUMID HEAT AGING TEST (60°C, 95% RH) with reflectivity decay ≤3%, reducing solid waste from frequent replacements and suitable for retrofitting old buildings in Russia.

V. TRADSARK Severe Cold Region Cases: Dual Breakthroughs in Energy Efficiency and Ecology

(1) St. Petersburg Apartment Renovation, Russia

- Challenge: A 20th-century Soviet-era building with poor wall insulation, indoor winter temperature only 12°C, and high energy consumption.

- Solution: Installed 0.08mm thick reflection film + 30mm XPS insulation board, paired with smart water distributors.

- Outcome: Indoor temperature stabilized at 20°C, natural gas consumption dropped 40%, annual heating costs reduced by ~$800 per household, and the renovated building received Russia’s “Green Energy-Efficient Housing” certification.

(2) Altay Guesthouse Project, Xinjiang, China

- Innovation: Used reflection film + phase-change energy storage flooring (paraffin-based phase-change materials) to store solar heat during the day and release it at night.

- Benefits: Renewable energy utilization increased to 35%, carbon emissions reduced by 65% compared to traditional coal heating, making it a “net-zero guesthouse” benchmark in Altay.

Conclusion: The Warmth Revolution in Severe Cold Regions Starts with a Reflection Film

TRADSARK’s Energy Saving Aluminum Foil Insulation Mirror Reflection Film is not just an efficiency upgrade for underfloor heating systems but also a key step toward green heating in cold regions. Through material innovation, system synergy, and full-life-cycle environmental design, it ensures every unit of heat is used efficiently and every degree of warmth is achieved without ecological compromise.

Against the backdrop of global carbon neutrality goals and energy transition, choosing TRADSARK means safeguarding warmth in severe cold with technology and defining future heating with sustainability.

Contact Us: Get customized underfloor heating solutions for severe cold regions, ensuring energy efficiency and warmth arrive hand in hand.

TRADSARK – The Guardian of Energy Efficiency in Extreme Cold