Product Overview

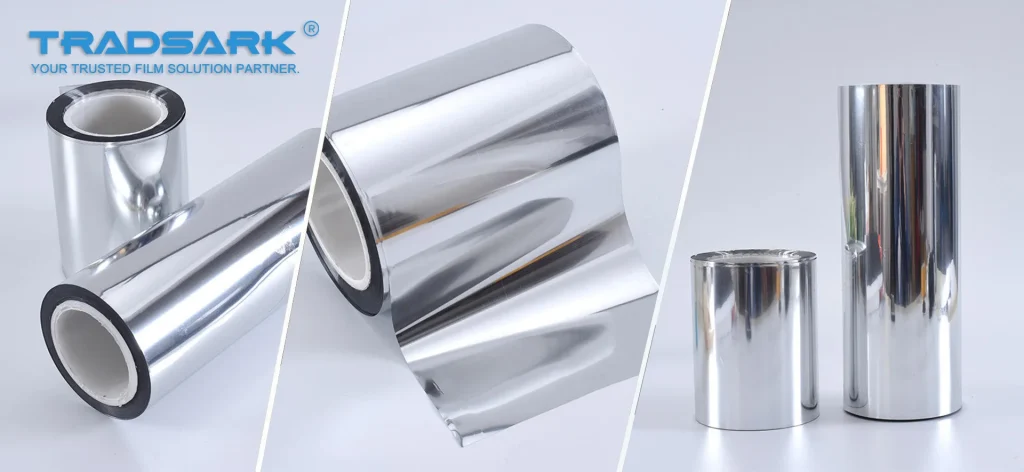

What is VMPET + PE Insulation Film?

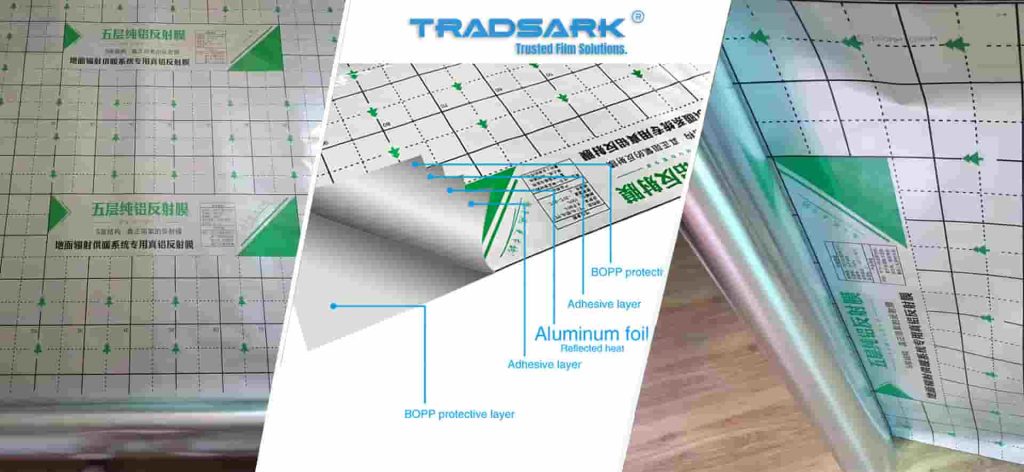

VMPET + PE insulation film is a composite material consisting of a metalized PET layer coated with polyethylene. The VMPET layer provides high reflectivity to sunlight and thermal radiation, while the PE layer ensures flexibility, durability, and moisture protection.

This unique combination makes the material lightweight, easy to install, and highly effective in thermal insulation applications. It can be laminated with various insulation materials to enhance thermal performance.

Material Composition

-

VMPET (Vacuum Metallized PET):

-

Provides thermal reflection and barrier properties.

-

Blocks radiant heat, reducing energy consumption in buildings.

-

-

PE (Polyethylene) Coating:

-

Adds flexibility, toughness, and moisture resistance.

-

Protects the metallized layer from mechanical damage and environmental factors.

-

Specifications

| Film Type | VMPET Thickness | PE Thickness | Width | Roll Length | Max Roll Diameter |

|---|---|---|---|---|---|

| Standard | 6 μm | 2 μm | ≤2050 mm | 1,000–50,000 m | 800 mm |

| Standard | 6 μm | 3 μm | ≤2050 mm | 1,000–50,000 m | 800 mm |

| Standard | 6 μm | 5 μm | ≤2050 mm | 1,000–50,000 m | 800 mm |

| Standard | 7 μm | 3 μm | ≤2050 mm | 1,000–50,000 m | 800 mm |

| Standard | 8 μm | 3 μm | ≤2050 mm | 1,000–50,000 m | 800 mm |

| Standard | 8 μm | 5 μm | ≤2050 mm | 1,000–50,000 m | 800 mm |

| Standard | 8 μm | 6 μm | ≤2050 mm | 1,000–50,000 m | 800 mm |

| Standard | 12 μm | 10 μm | ≤2050 mm | 1,000–50,000 m | 800 mm |

| Standard | 12 μm | 12 μm | ≤2050 mm | 1,000–50,000 m | 800 mm |

| Standard | 12 μm | 15 μm | ≤2050 mm | 1,000–50,000 m | 800 mm |

Custom thickness, width, and length can be produced based on customer requirements.

Technical Properties

| Property | Value | Test Method |

|---|---|---|

| Reflectivity | Up to 95% | ISO 13655 |

| Emissivity | E0.05 | ISO 13786 |

| Oxygen Transmission Rate | <15 cm³/m²•24h•0.1MPa | ASTM D1434 |

| Water Vapor Transmission Rate | <3.5 g/m²•24h | ASTM E96 |

| Tensile Strength (MD/TD) | 100/200 MPa | ASTM D882 |

| Elongation (MD/TD) | 150/50 % | ASTM D882 |

| Haze | ≤1.0 % | ASTM D1003 |

| Glossiness | Adjustable (Matte/Glossy) | ASTM D2457 |

| Corona Treatment | 40–50 dyne | ASTM D2578 |

Advantages

1. High Thermal Reflection

The metallized PET layer efficiently reflects radiant heat and sunlight, reducing heat absorption in flooring and building structures. It is highly effective in underfloor heating systems, contributing to energy savings and improved thermal comfort.

2. Moisture and Water Resistance

The PE layer prevents moisture penetration, protecting insulation materials from humidity and dampness, which can degrade thermal performance over time.

3. Versatility and Compatibility

VMPET + PE film can be laminated with bubble foams, EPE/XPE foams, and woven fabrics. It enhances the durability and thermal efficiency of insulation systems in floors, walls, and ceilings.

4. Lightweight and Cost-Effective

The film is lightweight, making transportation and installation easy. It reduces the overall weight of the insulation system while maintaining excellent thermal performance.

5. Environmental Friendliness

VMPET + PE is non-toxic, safe, and recyclable, meeting modern construction sustainability standards.

6. Easy Installation

Flexible and durable, the film can be cut to size, overlapped, and sealed to create continuous insulation layers without gaps.

Applications

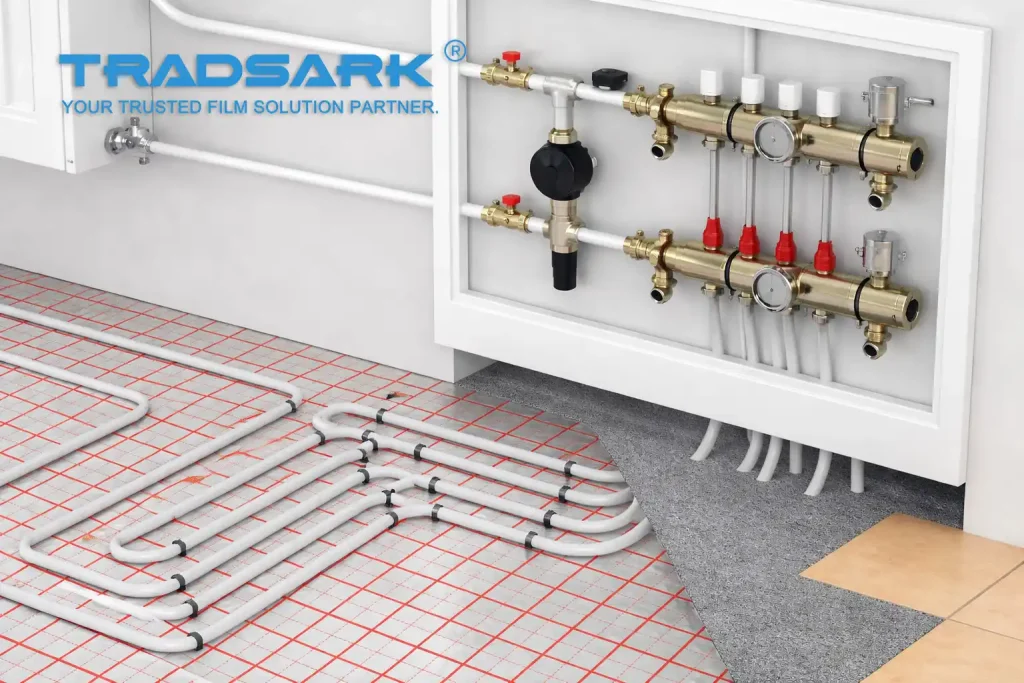

Underfloor Heating Systems

-

Acts as a reflective barrier below polyethylene foam or bubble insulation.

-

Improves heat distribution and efficiency in electric and hydronic heating systems.

Building Insulation

-

Suitable for residential, commercial, and industrial insulation projects.

-

Can be laminated with EPE/XPE foams to enhance thermal performance.

Industrial and Commercial Use

-

Used in cold storage, warehouses, and factories to improve energy efficiency.

-

Protects sensitive equipment from thermal fluctuations.

Energy-Saving Projects

-

Reduces heating and cooling energy consumption.

-

Reflective layer ensures maximum efficiency of insulation materials.

Installation Guidelines

-

Preparation: Ensure insulation surface is clean, dry, and free from sharp debris.

-

Cutting: Measure and cut VMPET + PE film according to project specifications.

-

Placement: Lay reflective side facing up for optimal heat reflection.

-

Lamination: Combine with bubble foams or XPE/EPE sheets using heat or adhesive lamination.

-

Sealing: Overlap edges and seal with reflective tape to prevent heat leakage.

-

Inspection: Ensure continuous coverage, no wrinkles, and proper adhesion.

Common Questions (FAQ)

Can VMPET + PE film be reused?

Yes, if carefully removed and stored, it maintains reflective and barrier properties.

Is it suitable for outdoor use?

Primarily designed for indoor applications. For outdoor use, protect from mechanical damage and prolonged UV exposure.

How does it enhance energy efficiency?

The reflective layer reduces radiant heat loss and improves underfloor heating performance, lowering energy costs.

Is the material environmentally friendly?

Yes, it is recyclable, non-toxic, and meets green building standards.

Maintenance and Storage

-

Storage: Keep in dry, cool, and shaded areas. Avoid direct sunlight exposure.

-

Handling: Use gloves to prevent scratching the metallized layer.

-

Cleaning: Wipe gently with a soft cloth; avoid abrasive materials.

Performance Comparison

| Feature | VMPET+PE | Aluminum Foil | Standard PE Film |

|---|---|---|---|

| Reflectivity | High (up to 95%) | Very High | Low |

| Flexibility | Excellent | Low | High |

| Moisture Resistance | Excellent | Good | Moderate |

| Durability | High | Moderate | Low |

| Cost | Moderate | High | Low |

Conclusion

VMPET + PE Insulation Film is a premium reflective thermal insulation solution, combining the advantages of metallized PET and polyethylene. Its versatility, durability, and high performance make it ideal for underfloor heating systems, laminated insulation panels, and energy-saving building projects. With customizable specifications and a wide range of applications, VMPET + PE film ensures cost-effective, long-lasting thermal insulation for residential, commercial, and industrial use.