| Product Type: Cast polyethylene film | |||

| Item | Unit | Typical Value | |

| Thickness | μm | 50-100 | |

| Density | g/cm² | 0.89 | |

| Tensile Strength | MD | N/mm² | ≥30 |

| TD | N/mm² | ≥20 | |

| Heat Shrinkage | MD | % | ≤1.0 |

| TD | % | ≤1.0 | |

| Elongation at Break | MD | % | ≥350 |

| TD | % | ≥450 | |

| Friction Coefficient | Static | ≤0.8 | |

| Dynamic | ≤0.8 | ||

| Sealing Strength | N/15mm | 125oC≥8 | |

| Haze | % | ≤3.5 | |

| Gloss | % | ≥75 | |

| Surface tension | mN/m | ≥38 | |

| Type | Cast Polyethylene Film | Application | Packaging |

| Thickness(μm) | 30~50 | Certificate | ISO9001/ CE/ UL |

| Width(mm) | 300~4000 mm | Package | Pallet |

| Diameter(mm) | 240~400 | Sample | Free |

| Paper Core(inch) | 3″/6″ | Payment | T/T, LC, PayPal, Westunion |

| Material | polyethylene | MOQ | 1000KG |

| Corona Treatment | None | Port | Qingdao Port |

| Processing Type | Cast | Place of Origin | China |

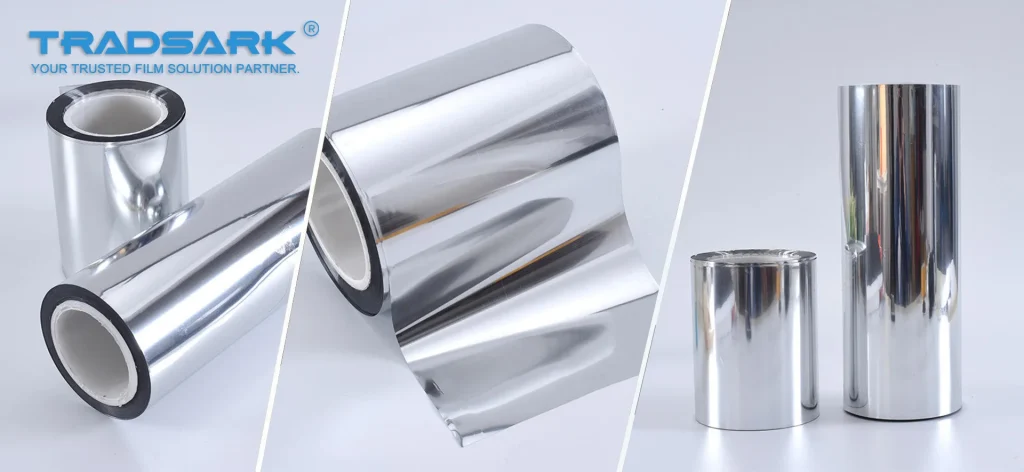

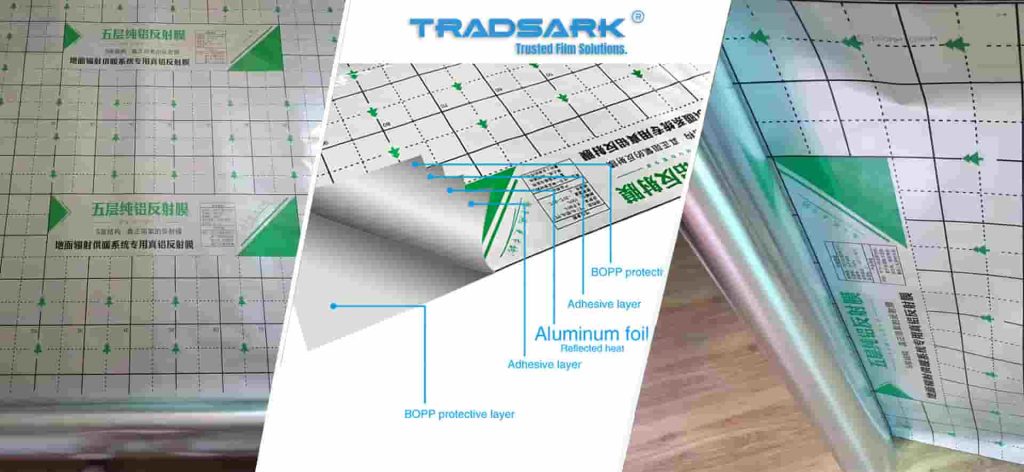

PE Film: Features and Advantages

PE film is produced using polyethylene resin, which can be processed through various techniques such as casting and extrusion to achieve different types of films. It can be produced in different thicknesses and grades, depending on the intended application. This film is lightweight yet durable, offering significant flexibility, moisture resistance, and excellent sealing properties.

Key Advantages of PE Film:

-

Excellent Barrier Properties: PE film effectively blocks moisture, dust, and contaminants, ensuring the freshness and longevity of packaged products.

-

High Flexibility: Offers flexibility to adapt to different product shapes and sizes, making it ideal for various packaging applications.

-

Durability and Strength: Resistant to tears, punctures, and physical damage, ensuring that products remain intact during transportation and storage.

-

Transparency: Provides high clarity, making it perfect for showcasing the product inside, enhancing visual appeal for consumers.

-

Environmentally Friendly Options: Available in recyclable and biodegradable variants, PE film supports eco-conscious packaging practices.

Key Applications of PE Film

PE film’s broad range of applications showcases its importance in many industries. Here’s how PE film is used across different sectors:

Food Packaging

PE film is widely used in food packaging to extend shelf life, maintain freshness, and protect food from external contaminants. Its ability to act as a moisture and oxygen barrier helps preserve the product’s quality for longer periods. Common applications include:

-

Fresh Produce Packaging: Protects fruits, vegetables, and herbs from moisture and bacteria.

-

Snack Packaging: Provides a durable seal for snack bags, preventing air and moisture from affecting the contents.

-

Frozen Foods: Keeps frozen foods protected from environmental factors while maintaining visibility.

Pharmaceutical Packaging

PE film plays a critical role in the safe packaging of drugs and medical devices, offering essential protection from moisture, dust, and other contaminants. It ensures the integrity and safety of the pharmaceutical products, keeping them in a sealed, sterile environment.

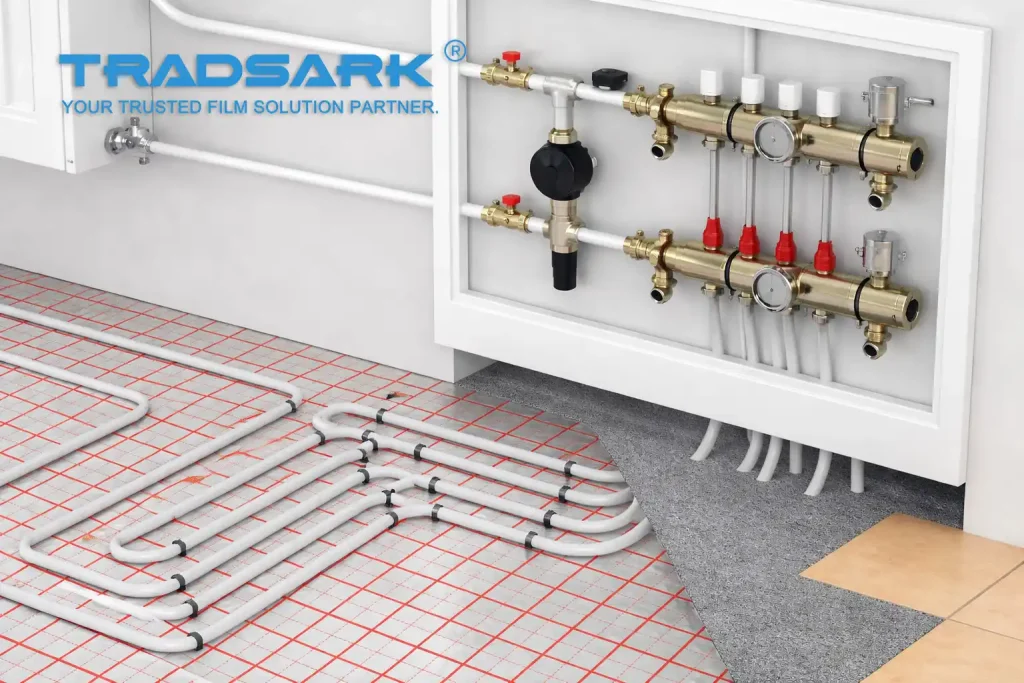

Agricultural Uses

In the agriculture industry, PE film is used as a protective covering for crops, preventing exposure to harmful environmental factors such as extreme weather, pests, and diseases. It is especially valuable for greenhouse films and crop protection sheets.

Industrial Product Packaging

PE films are commonly used to package various industrial components and products to protect them from physical damage. Whether used for packaging machinery parts, components, or hardware, PE film ensures durability and maintains product quality during handling and transportation.

Consumer Electronics Packaging

PE film provides protection for electronic devices and accessories by offering anti-static properties, moisture protection, and durability. It is widely used for packaging mobile phones, laptops, and other sensitive electronic products, ensuring they remain safe during shipping.

Household Goods Packaging

PE film is used for packaging a wide variety of household items and consumer goods, such as cleaning agents, toiletries, and personal care products. The film’s resistance to moisture, dust, and contamination helps maintain the integrity of these products during storage and transport.

Why Choose Tradsark’s PE Film Solutions?

At Weifang Tradsark New Materials Co., Ltd., we specialize in providing high-quality PE films that meet the stringent packaging requirements of various industries. Our PE films are produced with cutting-edge technology and are customizable to meet your specific needs.

Product Certifications:

-

FDA Food-Grade Certification: Ensuring the safety of food packaging.

-

ISO 9001: Quality management for consistent product quality.

-

ISO 14001: Environmental management standards for sustainable practices.

-

ISO 45001: Occupational health and safety standards.

-

CE Certification: Compliance with European safety and environmental standards.

Why Tradsark’s PE Films Stand Out:

-

Versatility: Our PE films are adaptable to various packaging needs, offering a wide range of properties including heat resistance, high transparency, and strength.

-

Customization: We provide customized PE film solutions tailored to meet specific industry and product requirements.

-

Reliability: Our films are produced using the latest technology, ensuring consistent performance and long-term reliability.

-

Sustainability: We offer eco-friendly PE film options that align with global sustainability goals.

Get in Touch with Tradsark Today

If you’re looking for reliable and high-performance PE films, Weifang Tradsark New Materials Co., Ltd. is your trusted partner. We are committed to providing the best packaging solutions for food, pharmaceuticals, agriculture, electronics, and more.

📞 Contact us today to request a free quote or for more information about our PE film solutions!

📧 Email: info@tradsark.net

📞 Phone: +86 190 0646 0458

Let Tradsark be your go-to supplier for all your PE film packaging needs, ensuring your products stay fresh, protected, and appealing.