2. Key Features

✔ Excellent Barrier Performance

-

Low oxygen transmission rate (OTR)

-

Prevents oxidation, aroma loss, contamination

-

Enhances freshness and shelf life

✔ Superior Mechanical Strength

-

High tensile strength in both MD & TD

-

Strong puncture and tear resistance

-

Ideal for frozen food, vacuum packaging, and sharp-edge products

✔ High Transparency & Optical Clarity

-

Premium gloss

-

Low haze

-

Enhances product visibility and packaging aesthetics

✔ Wide Temperature Resistance

-

Retort sterilization: up to 121°C

-

Deep-freeze: –40°C

Suitable for freezing, boiling, steaming, microwaveable, and retort pouches.

✔ Excellent Lamination & Printing Performance

-

High surface energy (≥50 dyn/cm)

-

Suitable for multi-layer lamination such as PA/PE, PA/CPP, PA/AL/PE, PET/PA/PE

-

Stable corona treatment, ideal for high-speed printing

✔ Chemical and Oil Resistance

-

Resistant to oils, fats, aromatic chemicals

-

Great for liquid seasonings and oily foods

3. BOPA Film Technical Date Sheet

| Technical Parameter of 15mic BOPA Film | ||||

| Item | Units | Test standard | Standard value | |

| Thickness | um | GB/T 6672-2001 | 10-30 | |

| Tensile strength | MD | Mpa | GB/T 13022-1991 | 230 |

| TD | GB/T 13022-1991 | 260 | ||

| Elongation at Break | MD | % | GB/T 13022-1991 | 110-150 |

| TD | GB/T 13022-1991 | 90-130 | ||

| Modulus of Elasticity | MD | Mpa | GB/T 13022-1991 | 2000 |

| TD | GB/T 13022-1991 | 1550 | ||

| Thermal shrinkage | MD | % | GB/T 12027-2004 | ≤2.0 |

| TD | ≤2.0 | |||

| Tear force | MD | mN | GB/T 11999-1989 | 54 |

| TD | 39 | |||

| Coefficient of Friction(non/non) | ST | GB/T 10006-1988 | 0.25 | |

| KI | 0.4 | |||

| Treated side(treated/non-treated) | mN/m | GB/T 14216-1993 | ≥50 | |

| Haze | % | GB/T 2410-1980 | 4.5 | |

| Gloss | % | GB/T 2410-1980 | 100-110 | |

| Clarity | % | GB/T 2410-1980 | >90 | |

| Water vapor transmission(40ºC 90%RH) | g/m²/24h | GB1037-88 | <150 | |

| /atm | ||||

| Oxygen transmission(20ºC100%RH) | cm³/m² | GB-1038 | <50 | |

| /24h /atm | ||||

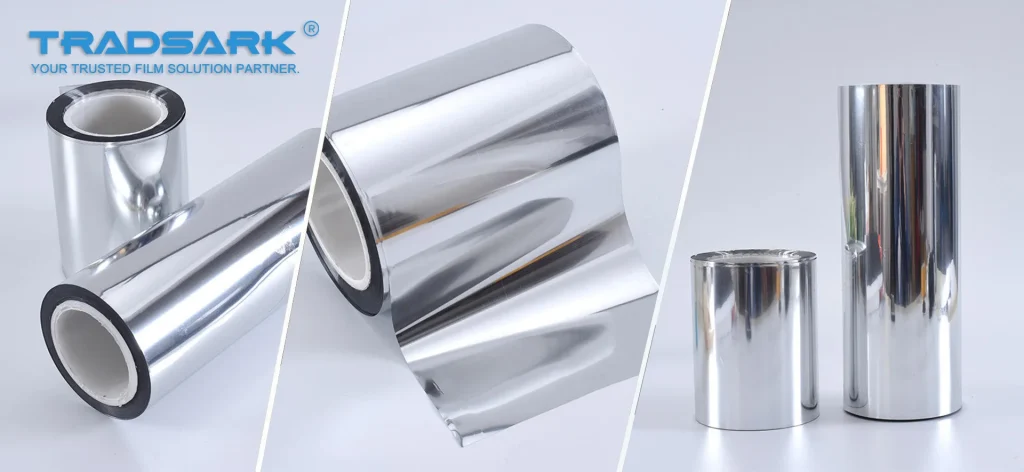

BOPA Film Specification

| Type | Nylon Film/Polyamide Film | MOQ | 1000KG |

| Thickness (μm) | 10~40 | Certificate | ISO9001 / CE / UL |

| Width (mm) | 300~2100 | Package | Pallet |

| Diameter (mm) | 240~400 | Sample | Free |

| Paper Core (inch) | 3″/6″ | Payment | T/T, LC, PayPal, Western Union |

| Material | Nylon6 | Application | Packaging/Printing/Lamination |

| Corona Treatment | One or Both Sides | Port | Qingdao Port |

| Processing Type | Biaxially Oriented | Place of Origin | China |

4. Production Technology

1. Biaxial Stretching Process

Tradsark adopts internationally advanced simultaneous and sequential stretching technologies, ensuring stable film thickness, high uniformity, and excellent optical properties.

Sequential Stretching (Mainstream Technology)

-

Stretching → MD → TD

-

Advantages: cost-effective, consistent quality, suitable for general high-barrier packaging

Simultaneous Stretching (High-End Technology)

-

MD & TD stretched at the same time

-

Advantages:

-

Ultra-low shrinkage

-

Best film flatness

-

Superior clarity

-

Better strength balance

Used in high-performance applications.

-

2.PA6 Resin & Copolyamides

-

Low moisture & low monomer content

-

Stable extrusion

-

Excellent barrier & thermoformability

-

Available with EVOH co-extrusion for ultra-high barrier

3. Film Structures Available

-

Mono-layer PA film

-

Co-extruded PA/PA

-

PA/EVOH/PA (high barrier)

-

PA with customized functional coatings

5. Applications

1. Food Packaging

BOPA is widely used in high-end food packaging due to its barrier and mechanical properties:

-

Frozen food packaging

-

Vacuum bags for meat, cheese & seafood

-

Retort pouches for ready-to-eat meals

-

Liquid seasoning bags (soy sauce, vinegar, oil)

-

Snack, nuts, dried fruit packaging

-

Coffee & tea bags

-

Oily and sharp packaging items

2. Pharmaceutical & Medical Packaging

-

Sterilization pouches

-

Medicine sachets

-

Diagnostic kits

-

Medical devices requiring high barrier

3. Industrial & Chemical Packaging

-

Pouches for chemicals, detergents, additives

-

Industrial parts & electronics moisture-protection bags

-

High durability flexible laminates

4. High-Performance Laminates

BOPA enhances the toughness and barrier of multi-layer structures:

-

NY/PE

-

NY/CPP

-

PET/NY/PE

-

AL/NY/PE

-

NY/EVOH/PE (ultra-high barrier)

Ideal for long-distance transportation and harsh storage environments.

6. Product Options

Available Thickness

-

10μm, 12μm, 15μm, 20μm, 25μm, 30μm

(Custom sizes available)

Width Range

-

Up to 2200 mm (customizable)

Corona Treatment

-

Single-side or double-side

-

≥48–52 dyn

Color

-

Transparent (standard)

-

Custom colors available

7. Packaging & Logistics

-

Export-standard wooden pallets

-

Moisture-proof inner PE wrapping

-

Edge protection for roll stability

-

Suitable for sea, air, and land transportation

-

Full export documentation support (CO, Form A, Form E, MSDS, ROHS)

8. Why Choose Tradsark?

-

Professional manufacturer of BOPA, BOPET, BOPP, CPP, VMPET

-

Strict QA/QC system & advanced production technology

-

Fast delivery and international logistics support

-

Flexible customization (thickness, corona, width, lamination grade)

-

OEM/ODM available

-

Competitive pricing with global export support