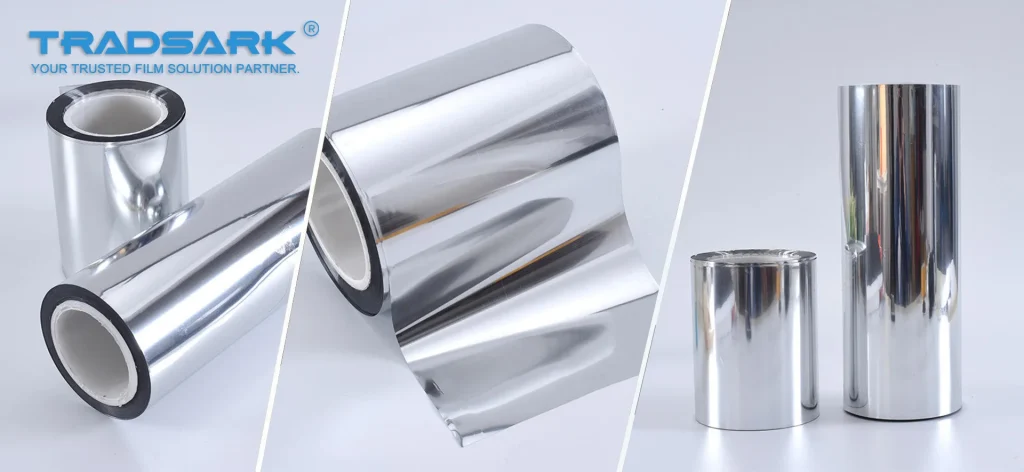

What Is Thermal Metalized Film?

Core Definition

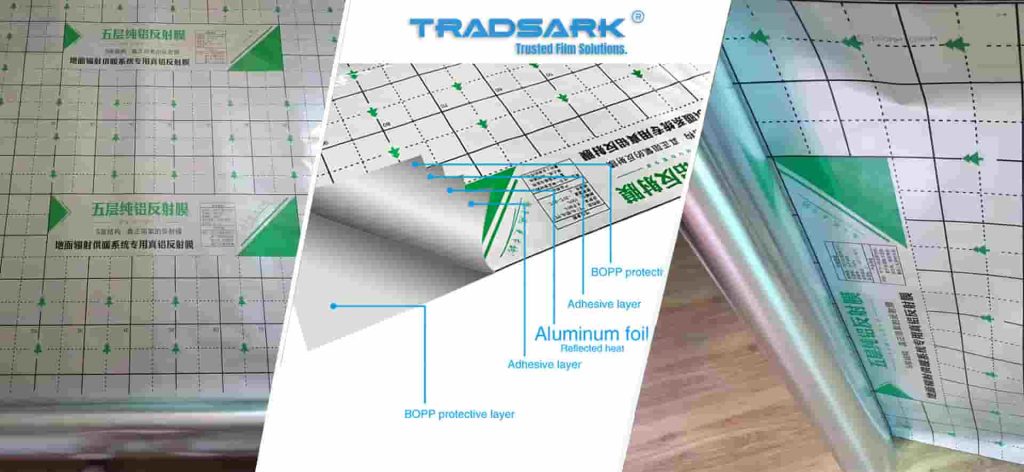

Thermal Metalized Film is a composite material created by depositing an ultra-thin layer of metal—commonly aluminum, copper, or nickel—onto the surface of plastic substrates such as PET or PP. This is achieved via vacuum evaporation or sputtering technologies. The resulting film merges the thermal and electrical properties of metals with the processability and flexibility of plastics.

This dual functionality makes Thermal Metalized Film ideal for applications where efficient heat dissipation, electrical performance, and barrier protection are essential, such as electronic components, battery packaging, and high-performance thermal insulation systems.

Composition & Structure

-

Plastic Substrate: PET, MPET, VMPET, or polypropylene (PP), providing high tensile strength, dimensional stability, and resistance to mechanical damage.

-

Metal Layer: Ultra-thin coating of aluminum, copper, or nickel, typically ranging from 100Å to 500Å, delivering reflectivity, electrical conductivity, and thermal management properties.

-

Optional Coatings: Corona or plasma-treated surfaces enhance adhesion for inks, laminates, or additional coatings.

Technical Specifications of Thermal Metalized Film

Tradsark provides highly customizable thermal metalized films to meet client-specific requirements. Typical specifications include:

| Material | PET, MPET, VMPET, Polyethylene terephthalate |

| Reflectivity | Up to 95% |

| Emissivity | Up to E0.05 |

| Optical Density(OD) | 1.62~3.6, customizable |

| Corona Treatment | 40-50 dyne, customizable |

| Permeability O2 TR | <15.0 cm3/(m2•24h•0.1MPa) |

| Permeability WVTR | <3.5 g /(m2•24h) |

| Width | 1m, 1.2m, 1.5m, 1.8m, 2m, 2.6m, customizable |

| Length | 1000m~36000m per roll, customizable |

Advantages of Thermal Metalized Film

Superior Thermal Conductivity

The metallic layer ensures rapid and uniform heat dissipation, making the film ideal for:

-

Electronics cooling (e.g., microchips, LED panels)

-

Battery pack insulation and thermal management in EVs

-

Heat-reflective films in building and industrial insulation

High Reflectivity & Barrier Performance

-

Reflects up to 95% of visible and infrared light, reducing heat absorption in sensitive applications.

-

Blocks oxygen and moisture penetration, preserving electronics, food, and pharmaceutical products.

Electrical Conductivity

-

Suitable for applications requiring electrostatic discharge (ESD) protection.

-

Supports flexible circuit components and EMI/RFI shielding.

Lightweight and Flexible

-

Reduces weight compared to traditional metal sheets or foils.

-

Can be laminated, folded, or cut without cracking, perfect for flexible electronics, packaging, and insulation films.

Cost-Effective and Sustainable

-

Uses minimal amounts of metal, lowering material costs while maintaining performance.

-

PET-based films are recyclable with proper separation techniques.

-

Reduced weight leads to lower shipping costs and carbon emissions.

Applications of Thermal Metalized Film

Electronics Industry

-

Microelectronics & Semiconductor Packaging: Provides ESD shielding, thermal dissipation, and moisture protection.

-

Capacitors & Insulators: Dielectric properties enhanced by metal layer for stable energy storage.

-

LED & Display Components: Reflective layers improve lighting efficiency and thermal control.

Packaging Industry

-

Flexible Food Packaging: Metalized PET films with low WVTR protect food from moisture and oxygen while providing a premium appearance.

-

Pharmaceutical Packaging: Blister packs and sachets maintain drug stability.

-

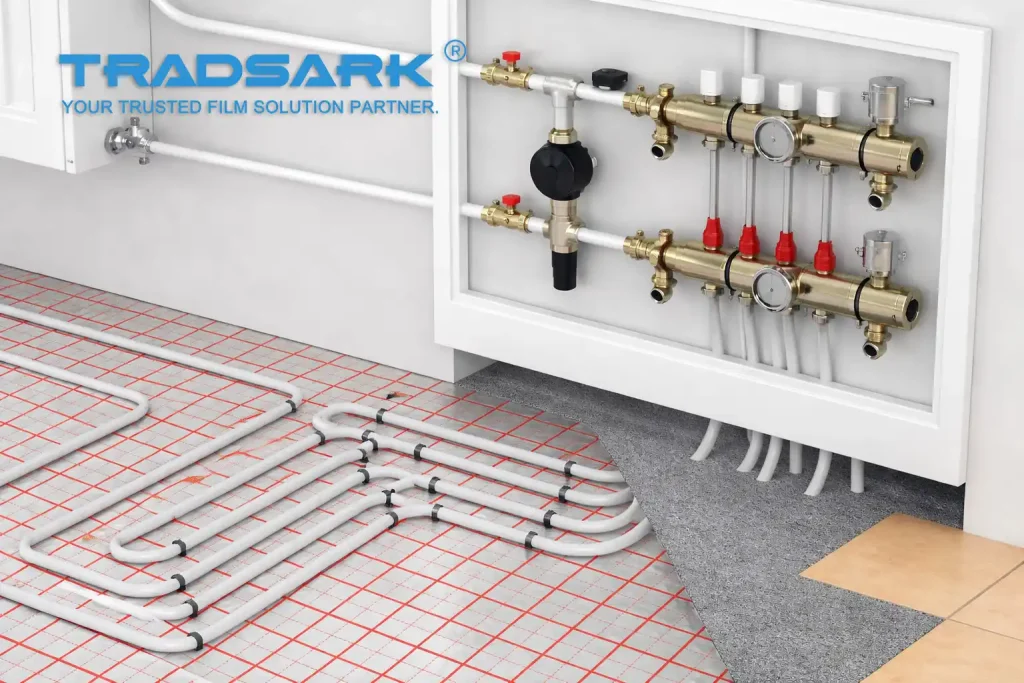

Battery Packaging: Thermal metalized films manage heat in lithium-ion battery packs.Thermal Management

-

Insulation Films: Used in building construction, automotive heat shields, and industrial machinery.

-

Heat Reflective Wraps: Reflects radiant heat, improving energy efficiency in heating and cooling systems.

Renewable Energy Applications

-

Solar Panels: Metalized PET layers act as reflective back sheets to enhance efficiency.

-

EV & Energy Storage: Thermal management layers for battery packs improve safety and performance.

Decorative & Industrial Uses

-

High-quality reflective and semi-reflective decorative films for packaging, gift wraps, and signage.

-

Laminates for high-end consumer products requiring metallic aesthetics.

Why Choose Tradsark Thermal Metalized Film?

-

Customizable Specifications: Thickness, width, roll length, and surface treatments tailored to your needs.

-

Advanced Production Facilities: Equipped with modern vacuum metallization and sputtering lines for uniform coating and high precision.

-

Global Supply Chain: Reliable international shipping and B2B support.

-

Technical Expertise: Decades of experience in PET film metallization for electronics, packaging, and insulation.

-

Sustainability Focus: Use of recyclable PET substrates and low-metal-content films.

How to Select the Right Thermal Metalized Film

Determine Application Requirements

-

Thermal Conductivity: Choose films with higher reflectivity and conductivity for electronics or insulation.

-

Barrier Properties: High OTR/WVTR for food, pharmaceutical, or sensitive electronics.

-

Mechanical Strength: Thicker films for industrial uses; thinner films for flexible packaging.

Evaluate Surface Treatments

-

Corona or Plasma Treatment: Improves ink and laminate adhesion.

-

Matte or Gloss Finish: Selection based on aesthetics or functional needs.

Regulatory Compliance

-

For food, medical, or consumer electronics, ensure compliance with standards like FDA, EU REACH, or ISO certifications.

Market Trends in Thermal Metalized Films

Sustainable Innovations

-

Recycled PET (rPET) and bio-based films are increasingly used to reduce environmental impact.

-

Water-based coatings replacing solvent-based coatings to minimize VOC emissions.

Enhanced Performance

-

Ultra-thin metal layers achieving high reflectivity with minimal material usage.

-

Integration of functional additives such as UV stabilizers and antimicrobial agents.

Growth in Electronics & Renewable Energy

-

Increasing use in EV batteries, solar panels, and high-performance electronics.

-

Demand for films with precise thermal management and ESD protection is rising globally.

Smart and Customizable Packaging

-

Films can incorporate QR codes, RFID tags, or other interactive features for traceability and consumer engagement.

-

Premium finishes and high-barrier properties drive growth in luxury food and cosmetic packaging.

Frequently Asked Questions (FAQs)

Is Thermal Metalized Film recyclable?

Yes, PET and BOPP substrates can be recovered using specialized recycling processes that separate the metal layer.

Can it be used in food or pharmaceutical packaging?

Yes, food-grade and medical-grade variants are available with FDA, EU REACH, and ISO compliance.

Does the metal layer affect flexibility?

No, films retain excellent flexibility and can be laminated, folded, or processed without cracking.

How long can the film maintain its thermal and barrier properties?

Shelf life varies by storage and application, but properly stored films maintain performance for 1–5 years for packaging and 10+ years for industrial insulation uses.

Conclusion

Thermal Metalized Film from Tradsark is a versatile, high-performance material ideal for electronics, packaging, thermal management, and decorative applications. Combining the thermal and electrical advantages of metals with the flexibility and processability of PET and other plastic films, these films provide superior barrier protection, reflectivity, and mechanical strength while reducing costs and environmental impact.

By selecting the right Thermal Metalized Film / Metalized PET Film / Aluminized Polyester Film, businesses can achieve optimal product performance, improved energy efficiency, and a premium appearance. Tradsark delivers consistent quality, global supply, and customization options, making us a trusted partner in metallized film solutions.