Product Overview

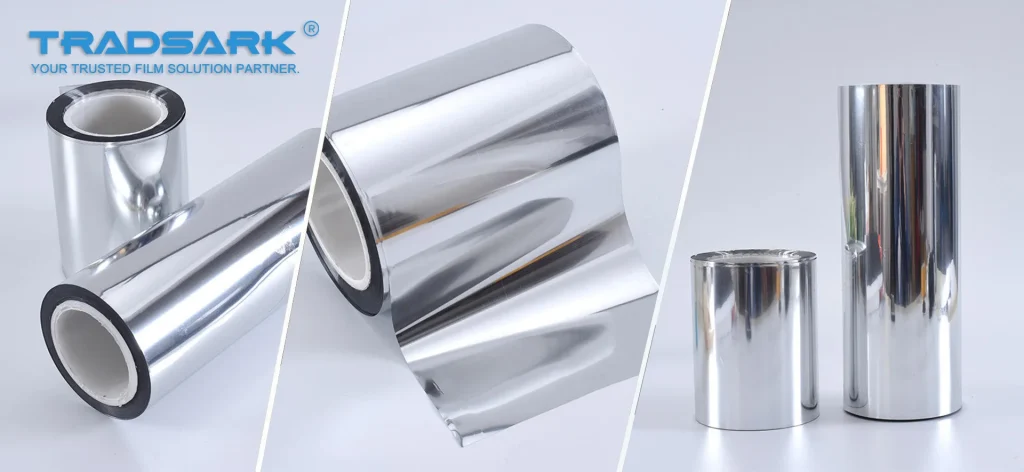

What is VMPET+PE Insulation Film?

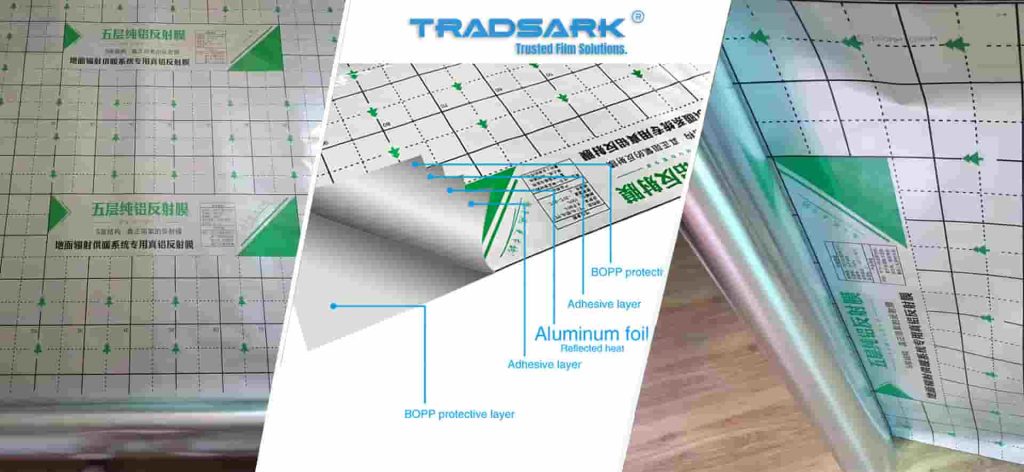

VMPET+PE insulation film is a composite material where a metalized PET layer is coated with a thin layer of polyethylene. The metallized PET layer reflects radiant heat, while the PE layer provides flexibility, waterproofing, and mechanical protection.

Key features include:

-

High reflectivity (up to 95%) for radiant heat.

-

Lightweight and flexible structure for easy installation.

-

Water-resistant and damp-proof properties.

-

Suitable for lamination with EPE, XPE, and other foam insulation materials.

Material Composition

-

Metalized PET (VMPET): Provides reflective and barrier properties, enhancing thermal insulation efficiency.

-

Polyethylene (PE) Coating: Adds flexibility, durability, and protects the metallized surface from moisture and mechanical damage.

Thickness and Dimensions

VMPET+PE films are available in a wide range of thicknesses to suit different insulation needs:

-

6μm VMPET + 2μm PE

-

6μm VMPET + 3μm PE

-

6μm VMPET + 5μm PE

-

7μm VMPET + 3μm PE

-

8μm VMPET + 3μm PE

-

8μm VMPET + 5μm PE

-

8μm VMPET + 6μm PE

-

12μm VMPET + 10μm PE

-

12μm VMPET + 12μm PE

-

12μm VMPET + 15μm PE

Custom thickness and widths up to 2050mm are available on request to meet specific project requirements.

Technical Specifications

| Feature | Specification | Unit | Test Method |

|---|---|---|---|

| VMPET Thickness | 6–12 μm | μm | ASTM D374 |

| PE Coating Thickness | 2–15 μm | μm | ASTM D374 |

| Reflectivity | Up to 95% | % | ISO 13655 |

| Emissivity | E0.05 | — | ISO 13786 |

| Width | ≤2050 | mm | — |

| Roll Length | 1,000–50,000 | m | — |

| Maximum Roll Diameter | 800 | mm | — |

| Water Vapor Transmission Rate (WVTR) | <3.5 | g/m²•24h | ASTM E96 |

| Oxygen Transmission Rate (OTR) | <15 | cm³/m²•24h•0.1MPa | ASTM D1434 |

| Corona Treatment | 40–50 | dyne | ASTM D2578 |

Advantages of Reflective Metalized PET Film

1. Superior Thermal Reflection

The metalized layer efficiently reflects sunlight and radiant heat, reducing heat absorption in buildings. This improves energy efficiency and helps maintain consistent indoor temperatures in underfloor heating systems.

2. Waterproof and Moisture-Proof

The PE coating provides excellent resistance to water and humidity, preventing moisture penetration and protecting the underlying insulation materials, such as foam boards or bubble films.

3. Compatibility with Insulation Materials

VMPET+PE film can be laminated with woven fabrics, EPE/XPE foams, and bubble foils to enhance insulation performance. The film forms a strong barrier layer, increasing the durability and lifespan of the insulation system.

4. Dust and Dirt Protection

The film prevents dust and debris from entering the insulation layer, ensuring the integrity and efficiency of the thermal insulation over time.

5. Durability and Eco-Friendliness

Made from high-quality PET and PE materials, the film is durable, flexible, and environmentally safe. It can be recycled or reused in various applications.

6. Easy Installation

The lightweight and flexible design allows for quick installation on floors, walls, or ceilings. It can be cut to size, folded, or overlapped to ensure complete coverage without compromising performance.

Applications

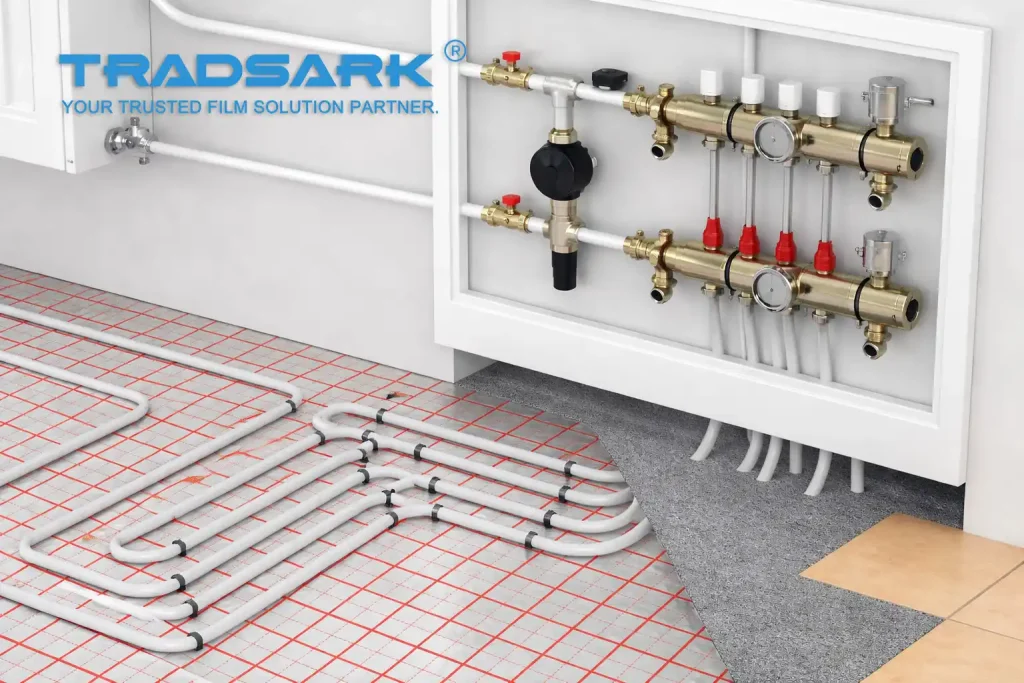

1. Underfloor Heating Systems

-

Acts as a reflective barrier under polyethylene foam or bubble insulation.

-

Enhances the efficiency of electric and hydronic floor heating systems.

-

Maintains heat distribution and reduces energy consumption.

2. Building Insulation

-

Suitable for walls, ceilings, and roof insulation projects.

-

Works in combination with EPE, XPE, or bubble foil insulation to improve overall thermal performance.

3. Industrial and Commercial Uses

-

Protects sensitive equipment from thermal stress.

-

Used in warehouses, cold storage, and other areas requiring temperature control.

4. Energy-Saving Construction Projects

-

Enhances energy efficiency in residential and commercial buildings.

-

Reflective surface helps reduce heating and cooling costs.

Installation Instructions

-

Surface Preparation: Ensure the floor or insulation surface is clean, dry, and free from sharp objects.

-

Cutting the Film: Measure the area and cut VMPET+PE film rolls to the required length.

-

Laying the Film: Place the film reflective side up for maximum heat reflection.

-

Lamination: If needed, laminate with EPE/XPE foams using heat or adhesive methods.

-

Sealing Edges: Overlap adjacent sheets and seal edges with reflective tape to prevent heat leakage.

-

Inspection: Ensure full coverage and check for wrinkles or gaps.

FAQ

Is VMPET+PE film reusable?

Yes, the film can be reused if carefully removed and stored, maintaining its reflective and barrier properties.

Can it be used outdoors?

It is primarily designed for indoor insulation. If used outdoors, it should be protected from mechanical damage and prolonged UV exposure.

How does it improve energy efficiency?

By reflecting radiant heat and reducing heat transfer, it enhances underfloor heating efficiency, lowering electricity or fuel consumption.

Is the film environmentally friendly?

Yes, both PET and PE materials are recyclable. The film is non-toxic and safe for building applications.

Summary

Reflective Metalized PET Film coated with PE (VMPET+PE) is a versatile, high-performance solution for underfloor heating and reflective insulation. Its combination of thermal reflection, moisture resistance, durability, and flexibility makes it ideal for modern energy-efficient buildings, industrial insulation, and commercial applications. With customizable thickness, width, and length, VMPET+PE insulation films can meet specific project requirements, ensuring optimal performance, cost-effectiveness, and long-term reliability.