What is PET + AL + PE Materials?

Core Definition

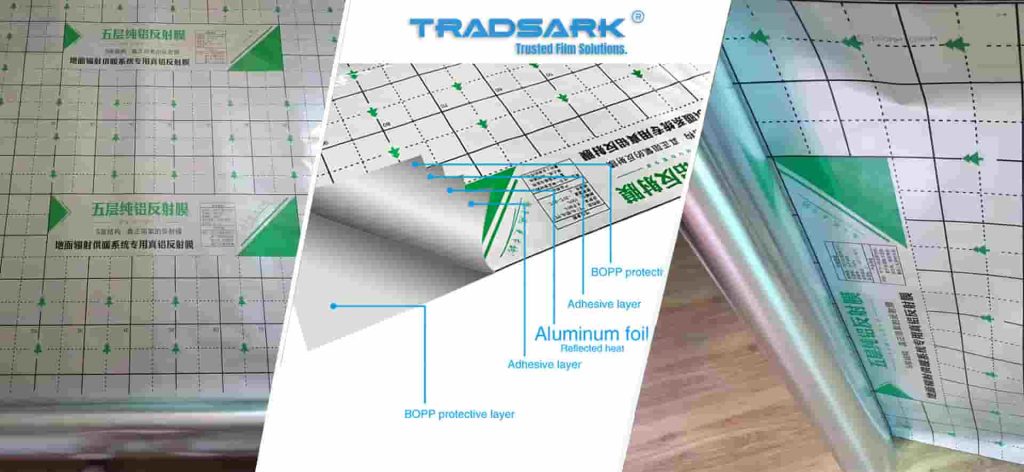

PET + AL + PE Materials is a multilayer composite material composed of:

-

PET Layer: Provides dimensional stability, high tensile strength, and flexibility for easy handling.

-

Aluminum Foil Layer: Offers high reflectivity (97–99%), acting as a barrier to radiant heat and reducing energy loss.

-

PE Coating Layer: Serves as an adhesive, moisture barrier, and protective layer to maintain the integrity of the aluminum foil.

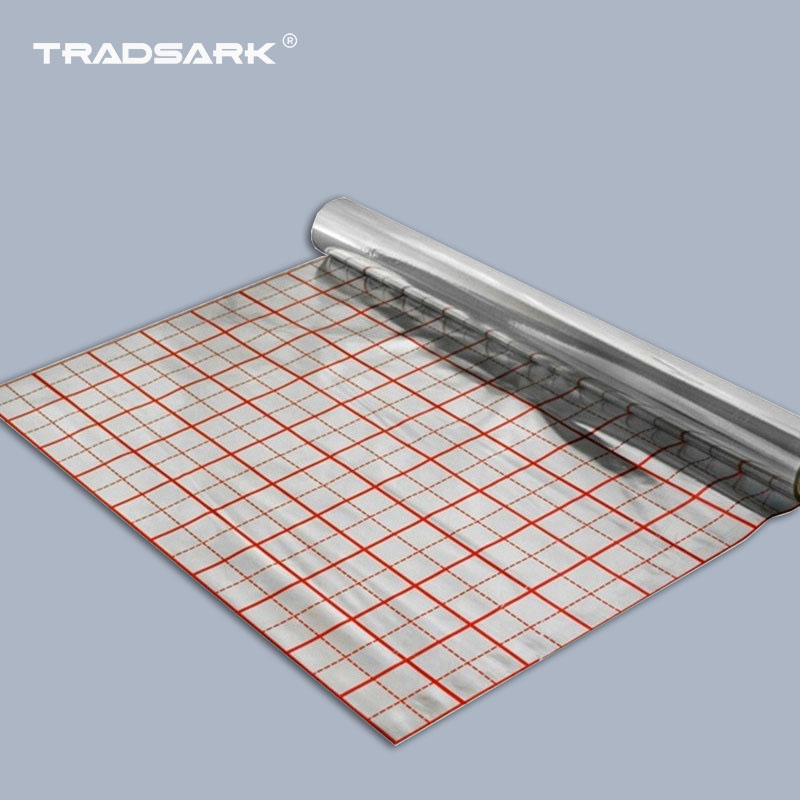

The combination of these layers produces a lightweight, durable, and thermally efficient insulation film suitable for underfloor heating and other thermal insulation applications.

Description

PET + AL + PE Materials can be customized according to specific project requirements. Standard thickness combinations include:

| PET Layer | Aluminum Foil | PE Layer |

|---|---|---|

| 12 μm | 9 μm | 10 μm |

| 12 μm | 7 μm | 10 μm |

| 10 μm | 9 μm | 10 μm |

| 8 μm | 6.5 μm | 8 μm |

| Custom combinations available | Custom | Custom |

Width Range: ≤2050mm

Length: 1000–50000m per roll

Core Size: 3″ / 6″, compatible with insulation lamination machines

Advantages

High Reflectivity and Thermal Efficiency

-

Aluminum layer reflects 97–99% of radiant heat.

-

Enhances energy efficiency in underfloor heating systems.

-

Ensures uniform heat distribution across floors, reducing cold spots and improving comfort.

Moisture and Water Resistance

-

PE coating provides excellent moisture resistance.

-

Prevents condensation under flooring, protecting foam insulation layers.

-

Maintains thermal efficiency even in high-humidity environments.

Durability and Mechanical Strength

-

PET layer offers dimensional stability and resistance to stretching or tearing.

-

Aluminum layer provides barrier properties, while PE protects against physical damage.

-

Resistant to punctures, bending, and prolonged pressure from flooring materials.

Installation Convenience

-

Lightweight and flexible for easy handling and cutting.

-

Compatible with EPE, XPE, and other foam lamination machines.

-

Can be rolled or laminated to large surfaces without additional adhesives.

Environmental and Safety Benefits

-

Made from recyclable PET, aluminum, and PE.

-

Non-toxic and safe for indoor use in residential or commercial buildings.

-

Contributes to reduced energy consumption and greenhouse gas emissions.

Applications

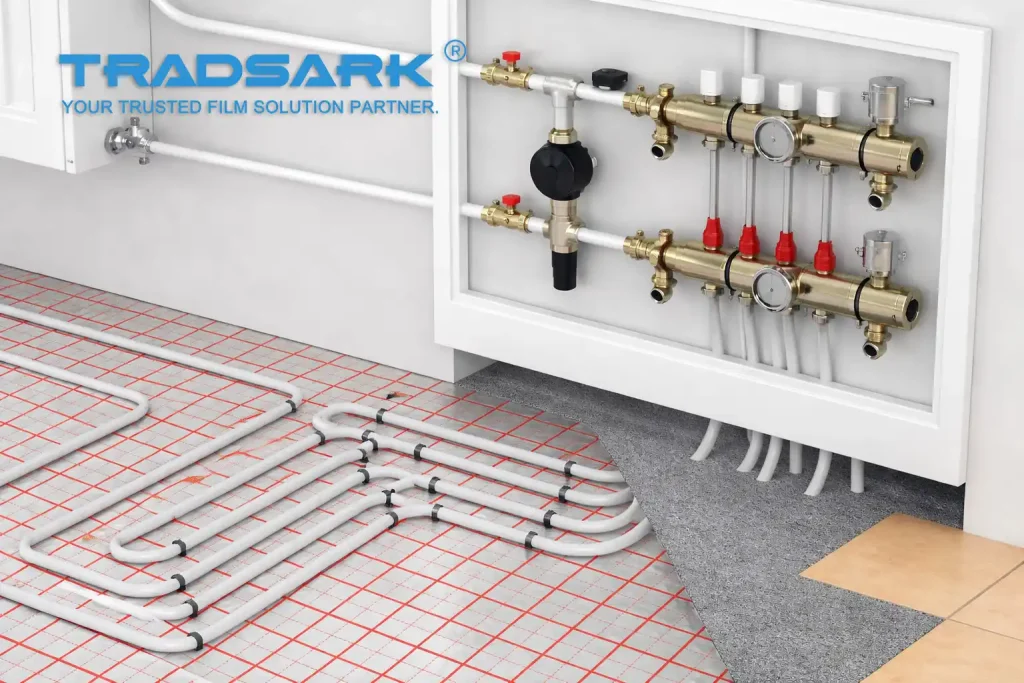

Underfloor Heating Systems

-

Used as a reflective insulation layer under radiant floor panels.

-

Maximizes heat reflection to improve energy efficiency.

-

Prevents heat loss to subfloor, improving the effectiveness of heating systems.

Foam Lamination

-

Laminates with EPE, XPE, or polyethylene foams to create thermal insulation panels.

-

Enhances mechanical strength and durability of insulation sheets.

-

Protects insulation materials from moisture, dust, and thermal degradation.

Construction Industry

-

Roof insulation: Reflects sunlight and prevents overheating.

-

Wall insulation: Reduces energy loss and improves indoor climate control.

-

Flooring: Ideal for residential, commercial, and industrial building insulation.

Industrial Applications

-

Protective insulation for piping, ducts, and machinery.

-

Thermal packaging for heat-sensitive products.

-

Insulation for electronics and industrial equipment requiring heat reflection.

Technical Performance

| Property | Value | Test Method |

|---|---|---|

| Reflectivity | 97–99% | ASTM E903 |

| Tensile Strength | PET: 130 MPa | ASTM D882 |

| Tear Resistance | High | ASTM D1004 |

| Moisture Barrier | Excellent | ASTM E96 |

| Thermal Resistance | High | ISO 8301 |

| Roll Width | ≤2050mm | — |

| Roll Length | 1000–50000m | — |

| Core Size | 3” / 6” | — |

Performance Highlights:

-

Excellent heat reflection for energy-efficient flooring.

-

Superior mechanical strength ensures durability during installation.

-

Moisture and vapor barrier protects laminated insulation materials.

Installation Guidelines

-

Surface Preparation: Ensure subfloor or foam insulation surface is clean, dry, and flat.

-

Film Orientation: Aluminum side should face the heat source for optimal reflection.

-

Lamination: Bond with EPE/XPE foam using hot melt lamination or mechanical fixing.

-

Sealing: Seal edges with reflective tape to prevent heat and moisture loss.

-

Periodic Maintenance: Inspect for minor tears or punctures; repair as needed.

Industry Case Studies

Residential Underfloor Heating

-

Large-scale residential apartment in Germany used PET + AL + PE reflective film under laminate flooring.

-

Resulted in 18% energy savings and more uniform heat distribution.

Commercial Buildings

-

Office buildings in the UK laminated PET + AL + PE film with XPE foam insulation.

-

Enhanced energy efficiency and indoor thermal comfort for multiple floors.

Industrial Applications

-

Factory in China applied PET + AL + PE film for protective insulation under heating pipes and machinery.

-

Maintained operational temperature stability and protected sensitive equipment.

Customization Options

-

Thickness: Adjustable to project needs (PET: 8–12 μm, AL: 6.5–9 μm, PE: 8–20 μm).

-

Width: Up to 2050mm for large-scale installations.

-

Length: Rolls from 1000–50000m.

-

Additives: Optional UV stabilizers, anti-aging agents, or fire retardants.

-

Colors: Silver metallic finish standard; can add coatings for aesthetics.

Frequently Asked Questions (FAQs)

Can PET + AL + PE film be used outdoors?

Yes, the film is moisture-resistant and UV-stabilized. However, it is primarily designed for indoor underfloor heating applications.

Is this film compatible with all foam types?

Yes, it can laminate with EPE, XPE, and polyethylene foam for reflective insulation panels.

Can the film be customized for large projects?

Absolutely. Thickness, width, length, and optional additives can be tailored to project requirements.

What is the expected lifespan of PET + AL + PE film?

With proper installation, the film can last decades while maintaining reflectivity, thermal performance, and mechanical integrity.

Conclusion

PET + AL + PE Materials / Underfloor Heating Aluminum Grid Film is a high-quality solution for reflective insulation applications. Its composite structure of PET, aluminum foil, and PE coating ensures exceptional heat reflection, moisture resistance, mechanical durability, and environmental safety.

Widely used in underfloor heating, foam lamination, and building insulation projects, this product improves energy efficiency, enhances thermal comfort, and reduces heating costs. Customizable for different project sizes and specifications, PET + AL + PE Materials offer a reliable, long-lasting, and environmentally friendly choice for modern insulation systems.