Key Features and Benefits of Metallized CPP Film

-

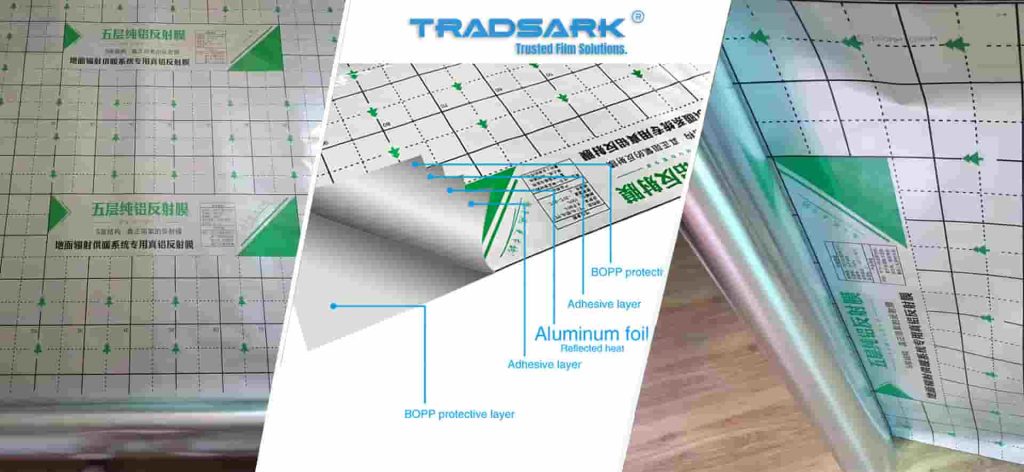

Excellent Gas and Moisture Barrier Properties

Metallized CPP film provides superior barrier protection, particularly against oxygen, moisture, and light. This makes it ideal for preserving food, pharmaceutical products, and other moisture-sensitive goods. The excellent gas barrier extends the shelf life of packaged products, ensuring they remain fresh and free from contamination. -

Enhanced Mechanical Strength and Puncture Resistance

Metallized CPP film offers superior mechanical strength and puncture resistance, making it ideal for packaging applications that require durability and protection against physical damage. This film can withstand rough handling, transport, and storage conditions, safeguarding the products inside from damage. -

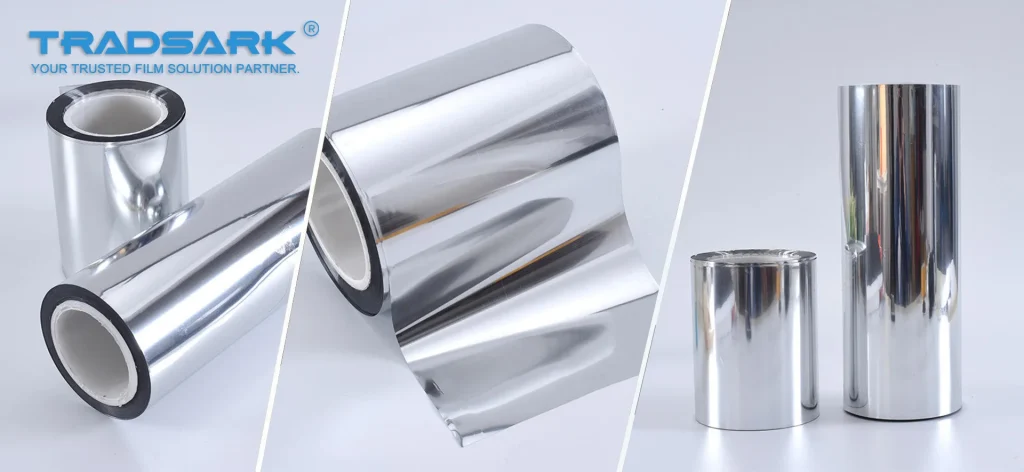

High Reflectivity and Gloss

The reflective aluminum coating gives the metallized CPP film a shiny, metallic appearance that enhances the visual appeal of the packaging. This high gloss and reflectivity not only make the packaging more attractive to consumers but also improve its shelf visibility, which is especially beneficial for retail and branding purposes. -

Compliant with Food Safety Standards

Metallized CPP film is widely used in food packaging due to its compliance with international food safety standards. It ensures the safety of the packaged contents by protecting against contamination, spoilage, and degradation, thus maintaining product quality and integrity. -

Good Chemical Stability and Resistance to Aging

This film is chemically stable and resistant to aging, making it a reliable choice for long-term use. It maintains its barrier properties and mechanical strength over time, ensuring that products remain protected throughout their shelf life. It is resistant to various environmental factors such as temperature fluctuations, moisture, and chemicals. -

Heat-Sealability

Metallized CPP film offers excellent heat-sealing properties, which make it suitable for automated packaging processes. Its ability to be sealed under high temperatures provides a secure and airtight seal, helping to prevent contamination and preserve the product’s freshness.

Metallized CPP Film Technical Date Sheet

| Properties | Unit | Standard Value | Test Value | Test Method |

| Thickness | μm | 20 | 20 | GB/T6672 |

| AL Thickness | Ω/□ | ≤2.5 | 1.78 | GB/T15717 |

| Adhesion of AL Layer | N/15mm | ≥2 | 5 | EAA |

| Initial heat sealing temperature (3N) | ℃ | 107-108 | 107.0 | BB/T 0030-2019 |

| Tensile Strength MD/TD | MPa | ≥35/≥25 | 58.9/51.8 | GB/T 1040.3 |

| Elongation at Break MD/TD | % | ≥280/≥380 | 370/460 | GB/T 1040.3 |

| MVTR(38°C,90%RH) | g/(m²·day) | ≤2.0 | 1.37 | ASTM F-1249 |

| OTR(38°C,90%RH) | cc/(m²·day) | 10-20 | 15.00 | ASTM D-3985 |

Specification

| Type | Metalized CPP Film | Application | Packaging |

| Thickness (μm) | 19~60 | Certificate | ISO9001 / CE / UL |

| Width (mm) | 300~2000 mm | Package | Pallet |

| Diameter (mm) | 240~400 | Sample | Free |

| Paper Core (inch) | 3″/6″ | Payment | T/T, LC, PayPal, Western Union |

| Material | Polypropylene & Aluminum | MOQ | 1000KG |

| Corona Treatment | One side | Port | Qingdao Port |

| Processing Type | Aluminum Coating | Place of Origin | China |

Applications of Metallized CPP Film

Metallized CPP film is a versatile material that can be used in a wide range of applications, including:

-

Food Packaging: Commonly used for packaging snacks, confectionery, dried foods, and other food products that require protection from moisture and oxygen. The film’s barrier properties help preserve the freshness and extend the shelf life of food items.

-

Pharmaceutical and Medical Packaging: Used for packaging pharmaceuticals, nutraceuticals, and medical devices, metallized CPP film ensures the products are kept safe from moisture, light, and air, which can compromise their effectiveness.

-

Cosmetic and Personal Care Packaging: Its high gloss and reflective surface make it an excellent choice for packaging high-end cosmetic products, such as lotions, creams, and perfumes, where aesthetics are important.

-

Industrial Applications: Metallized CPP film is also used in various industrial applications, including packaging for chemicals, electronics, and other goods that require protection from external environmental factors.

Advantages of Metallized CPP Film

-

Superior Barrier Protection: Offers excellent resistance to oxygen, moisture, and light, ensuring that packaged products stay fresh longer.

-

Durability and Puncture Resistance: Strong mechanical properties and resistance to physical damage ensure the film maintains its integrity throughout the supply chain.

-

Aesthetic Appeal: The reflective and glossy surface enhances the look of packaging, helping products stand out on the shelf.

-

Heat-Sealability: Metallized CPP film’s heat-sealability ensures secure packaging and an airtight seal.

-

Long-Term Use: Its chemical stability and resistance to aging make it a reliable material for extended product shelf life.

Conclusion

Metallized CPP Film is a high-performance material that combines barrier protection, durability, and visual appeal. With its excellent gas and moisture barrier properties, superior mechanical strength, heat-sealability, and compliance with food safety standards, it is an ideal choice for food, pharmaceutical, and industrial packaging. Whether for preserving the freshness of products or enhancing packaging aesthetics, metallized CPP film offers a versatile and reliable solution for various packaging needs.

For more information or to place an order, contact Tradsark New Materials Co., Ltd. today. We provide premium metallized CPP films designed to meet the diverse needs of industries worldwide.