Key Features and Benefits of Metallized CPE Film

-

High Barrier Properties

Metallized CPE film provides outstanding oxygen and moisture barrier protection, significantly extending the shelf life of packaged products. It helps to preserve the freshness, flavor, and quality of food products while preventing oxidation and moisture-related damage. This makes it an ideal choice for packaging perishable goods, pharmaceuticals, and sensitive products. -

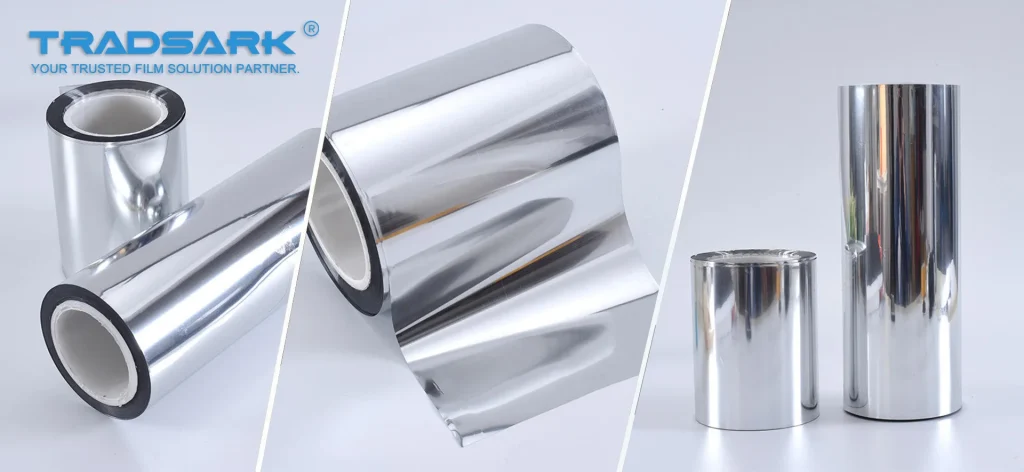

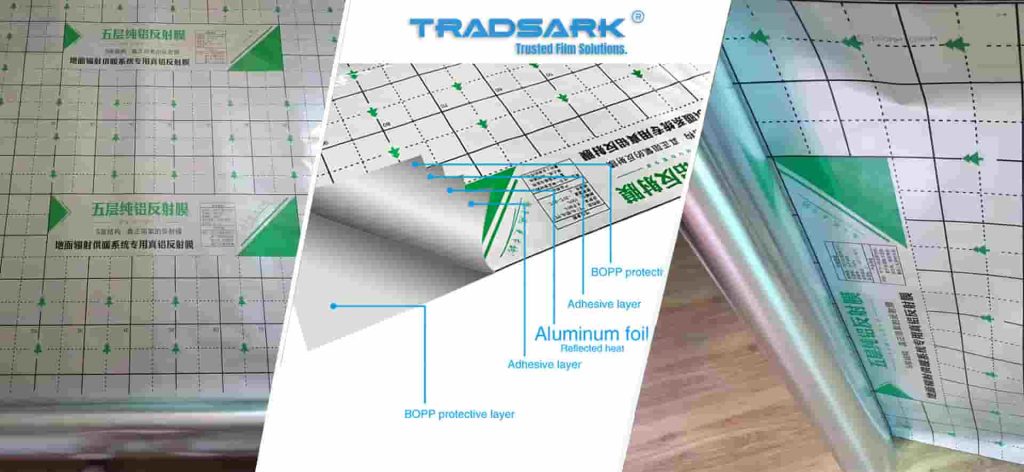

Excellent Gloss and Reflectivity

The aluminum coating on CPE film creates a high-gloss metallic finish, making the packaging more visually appealing. The reflectivity of the film enhances the aesthetic quality of the packaging, improving the product’s shelf presence and attracting consumer attention. This feature is especially important for luxury, cosmetic, and high-end food products that demand attractive packaging. -

Strong Mechanical Strength

Metallized CPE film offers excellent mechanical strength, including high tensile strength and durability. It is resistant to physical damage such as punctures, tears, and abrasions, ensuring that products remain protected during handling, transportation, and storage. This durability makes it an excellent choice for packaging that will undergo rough handling or exposure to harsh conditions. -

Good Printability and Processability

Metallized CPE film is compatible with various printing technologies, including flexographic, gravure, and offset printing. This makes it suitable for high-quality graphic design and branding, allowing companies to create attractive, eye-catching packaging that stands out. Additionally, it is easy to process, enabling efficient packaging production. -

Mono-Material Compatibility

Metallized CPE film is made from mono-material PE (Polyethylene), ensuring it is compatible with products designed for single-material packaging. This enhances the film’s versatility and makes it an environmentally friendly option. The single-material composition also ensures easier recycling and disposal, aligning with sustainability efforts in packaging. -

Wide Applications

Metallized CPE film is highly versatile and suitable for a wide range of industries. It is widely used in food packaging, including snacks, frozen foods, and convenience meals, where barrier properties are crucial for preserving freshness. Additionally, it is employed in pharmaceutical packaging, cosmetic packaging, and various industrial applications that require moisture and oxygen protection.

Metallized CPE Film Technical Date Sheet

| Properties | Unit | Standard Value | Typical Value | |

| Thickness | Tolerance | % | ±6.0 | +0.3 |

| Mean Deviatio | ±2.0 | +0.6 | ||

| Film Density | g/cm³ | / | 1.18 | |

| Sheet Resistance | Ω | / | 1.63 | |

| AL Thickness | Ω/□ | 1.21 | ||

| Uniform of AL layer | % | ±12 | 1.3 | |

| Adhesive Strength | % | ≤10 | 0 | |

| Wetting Tension (AL layer) | Dyne | ≥32 | 38 | |

| Coeff of Friction |

Dynamic | / | / | 0.121 |

| Static | / | / | 0.123 | |

| Tensile Strength |

MD | Mpa | ≥22 | 32 |

| TD | ≥18 | 21 | ||

| Elongation at Break |

MD | % | ≥500 | 733 |

| TD | ≥650 | 742 | ||

| Heat Seal Strength | n/15mm | / | 8 | |

Applications of Metallized CPE Film

-

Food Packaging: Ideal for packaging snacks, confectionery, dry food, and frozen foods, where it is essential to maintain the product’s quality and extend shelf life. The barrier properties protect against moisture and oxygen, keeping food fresh for longer periods.

-

Pharmaceutical Packaging: Used for packaging tablets, capsules, and medical devices that need protection from moisture, light, and oxygen. Metallized CPE film ensures that the products are kept in optimal conditions, preventing degradation.

-

Cosmetic and Personal Care Packaging: Perfect for packaging cosmetics, perfumes, creams, and lotions, where the visual appeal and protection of the product are of utmost importance. The film’s glossy surface enhances the packaging’s elegance while preserving the integrity of the contents.

-

Industrial Applications: Metallized CPE film is also used for packaging electronic components, chemicals, and other industrial products that require protection from environmental factors such as moisture and oxygen.

Advantages of Metallized CPE Film

-

Superior Barrier Protection: The film provides excellent resistance to oxygen and moisture, keeping products fresh and preventing spoilage.

-

Durable and Robust: Offers strong mechanical strength and is resistant to physical damage, including punctures and tears.

-

Aesthetic Appeal: The high-gloss finish and metallic luster make the packaging visually striking and appealing to consumers.

-

Versatile and Processable: It is compatible with a variety of printing technologies, making it easy to customize packaging with high-quality graphics.

-

Sustainability: Made from mono-material PE, the film is easy to recycle, aligning with environmental sustainability goals.

-

Long Shelf Life: The exceptional barrier properties of metallized CPE film extend the shelf life of packaged goods, reducing product waste.

Conclusion

Metallized CPE Film is a high-performance packaging solution that provides excellent oxygen and moisture protection, mechanical strength, and aesthetic appeal. With its high barrier properties, durability, and compatibility with printing technologies, it is an ideal choice for a wide range of applications across industries such as food packaging, pharmaceuticals, cosmetics, and more.

The film’s ability to preserve product freshness, its eye-catching appearance, and its sustainability make it a valuable material for businesses looking to deliver high-quality, attractive packaging while protecting their products. Whether you’re in the food, pharmaceutical, or cosmetic industry, metallized CPE film is an excellent choice to enhance your packaging solutions.