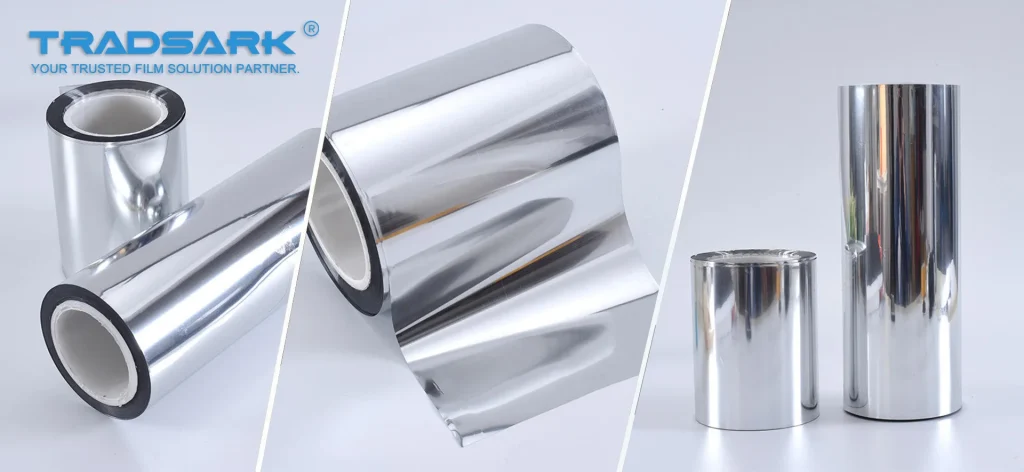

What is Metalized PET Film Coated PE?

Core Definition

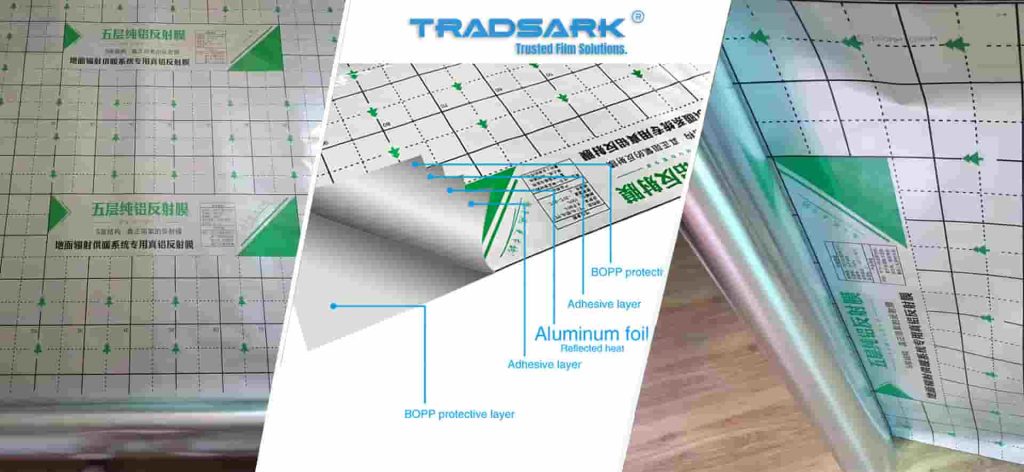

Metalized PET Film Coated PE consists of a thin VMPET layer (typically 6–12 microns) vacuum-coated with an ultra-thin aluminum layer, laminated with a polyethylene (PE) layer (2–15 microns). The combination delivers:

-

High reflectivity for solar heat and light.

-

Waterproof and damp-proof characteristics.

-

Flexibility for lamination with foam insulation materials.

Material Composition

-

Base Layer: PET metallized with aluminum, providing reflective properties and barrier resistance.

-

PE Coating: Enhances waterproofing, mechanical protection, and lamination compatibility.

-

Thickness Variations: Customizable to meet diverse thermal insulation requirements.

Specifications

| Material Composition | Thickness Options | Width | Notes |

|---|---|---|---|

| VMPET+PE | 6μm+2μm, 6μm+3μm, 6μm+5μm, 7μm+3μm, 8μm+3μm, 8μm+5μm, 8μm+6μm, 12μm+10μm, 12μm+12μm, 12μm+15μm | ≤2050mm | Customizable based on customer requirements |

Key Performance Metrics

-

Reflectivity: up to 95%

-

Moisture resistance: Excellent

-

Tear resistance: High

-

Durability: Long-lasting in outdoor and indoor applications

-

Environmentally friendly: Can be recycled or reused in insulation projects

Advantages

Reflective Thermal Insulation

-

The VMPET layer reflects sunlight and solar heat, reducing heat transfer.

-

Ideal for insulating building roofs, walls, and floors.

-

Enhances energy efficiency by reducing air conditioning and heating costs.

Waterproof and Damp-Proof

-

PE coating prevents moisture penetration and condensation.

-

Maintains insulation efficiency under humid or wet conditions.

-

Protects foam insulation materials such as EPE or XPE from water damage.

Laminating Compatibility

-

Can be laminated with woven materials, bubble foams, EPE/XPE foams.

-

Provides a smooth, adhesive-ready surface for composite insulation panels.

-

Flexible and easy to handle for large-scale building insulation projects.

Durability and Environmental Safety

-

Resistant to tearing, punctures, and aging.

-

Non-toxic, eco-friendly, safe for building and industrial applications.

-

Suitable for repeated use and long-term installations.

Dust and Moisture Prevention

-

Blocks dust particles, water vapor, and other contaminants.

-

Ensures the integrity and longevity of insulation foam layers.

-

Maintains indoor air quality when used in HVAC systems.

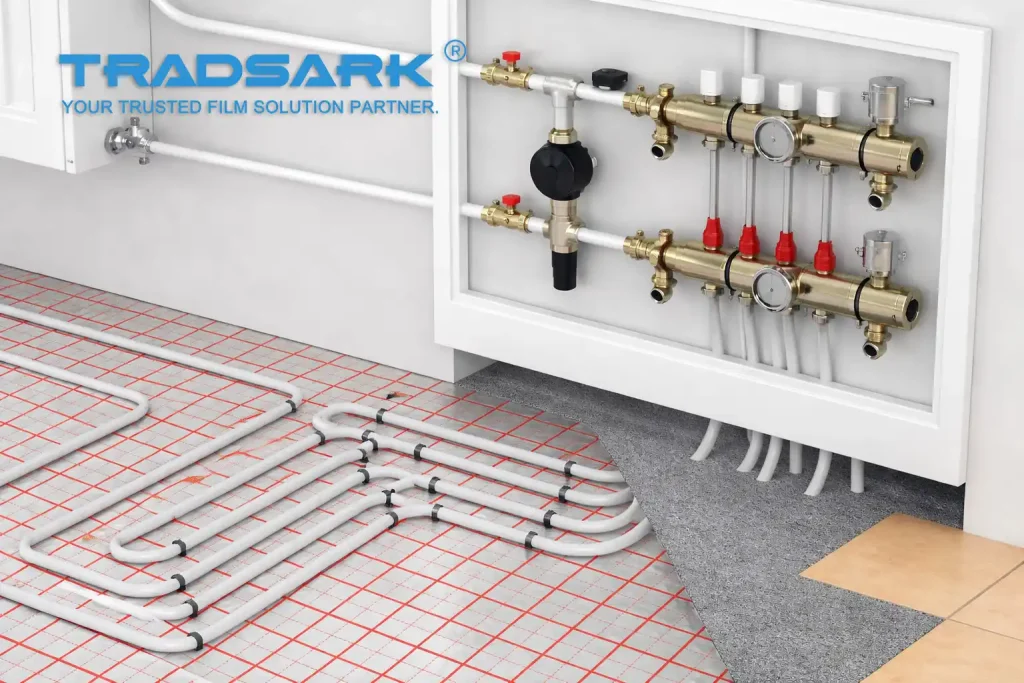

Applications

Building Thermal Insulation

-

Roof insulation: Reflects heat during summer and retains warmth in winter.

-

Wall insulation: Reduces energy loss and maintains temperature stability.

-

Floor insulation: Prevents cold conduction and improves indoor comfort.

Foam Lamination

-

Laminates with EPE, XPE, or bubble foam for packaging or building applications.

-

Ideal for producing reflective insulation blankets, panels, and sheets.

Packaging and Industrial Protection

-

Protects sensitive electronic equipment from heat and moisture.

-

Used in thermal packaging for food, pharmaceuticals, or chemicals.

HVAC and Duct Insulation

-

Prevents heat loss in air ducts and ventilation systems.

-

Reduces condensation and improves HVAC system efficiency.

Technical Advantages

High Reflectivity

-

Reflects up to 95% of solar radiation.

-

Reduces indoor temperature by 5–10°C in summer roof applications.

Thermal Conductivity

-

Low thermal conductivity enhances insulation performance.

-

Works efficiently with foam materials to create multi-layered thermal barriers.

Moisture Barrier

-

PE layer forms a tight barrier to prevent water vapor penetration.

-

Reduces risk of mold, mildew, and insulation degradation.

Mechanical Strength

-

Metallized PET layer provides high tensile strength.

-

PE coating adds flexibility and tear resistance.

-

Resistant to punctures, folds, and repeated handling.

Installation Guidelines

-

Surface Preparation: Ensure substrate or foam surface is clean and smooth.

-

Film Orientation: Place metallized side outward for reflective performance.

-

Lamination: Use adhesive or thermal lamination to bond with foam layers.

-

Fixing and Sealing: Seal edges with tape or heat sealing for maximum moisture protection.

-

Maintenance: Periodically inspect for damages; minor tears can be repaired with reflective tape.

Industry Case Studies

Reflective Insulation for Roofs

-

Large commercial building in Europe used VMPET+PE laminated with XPE foam.

-

Resulted in 15% energy savings on air conditioning during summer months.

Industrial Equipment Protection

-

Electronic factory used VMPET+PE film to insulate sensitive machinery.

-

Reduced heat transfer and prevented moisture-related failures.

Foam Packaging

-

Food industry laminated VMPET+PE with EPE foam for thermal transport packaging.

-

Maintained product temperature during 12-hour transit under high outdoor temperatures.

Customization Options

-

Thickness: From 6μm VMPET+2μm PE to 12μm VMPET+15μm PE.

-

Width: Up to 2050mm; custom widths for specific insulation applications.

-

Length: Rolls from 1000m–50000m, adjustable per project.

-

Additives: Anti-aging agents, UV stabilizers, fire retardants (optional).

-

Color Coating: Silver, metallic, or custom colors for aesthetic or functional purposes.

Environmental and Safety Considerations

-

Made from recyclable PET and PE materials.

-

Reduces energy consumption in buildings and packaging.

-

Non-toxic, safe for industrial, residential, and agricultural applications.

-

Can be combined with biodegradable layers for eco-conscious solutions.

Frequently Asked Questions (FAQs)

Can this film be used outdoors?

Yes, the VMPET+PE film is resistant to UV rays, water, and general outdoor conditions.

Is the film compatible with all types of foam?

Yes, it is compatible with EPE, XPE, and bubble foam, as well as woven materials.

Can the film be customized?

Yes, thickness, width, length, and additives can be tailored to your project.

What is the expected lifespan?

With proper installation and maintenance, the film can last for multiple years in insulation applications.

Conclusion

Metalized PET Film Coated PE (VMPET+PE) is a versatile, high-performance insulation material. Its combination of reflective metallized PET and waterproof PE provides superior thermal insulation, moisture protection, and durability. Widely used in building construction, foam lamination, industrial applications, and packaging, VMPET+PE enhances energy efficiency, protects materials, and ensures long-term performance.

Choosing VMPET+PE insulation film guarantees reliable protection, improved thermal efficiency, and environmentally friendly solutions for diverse insulation needs.