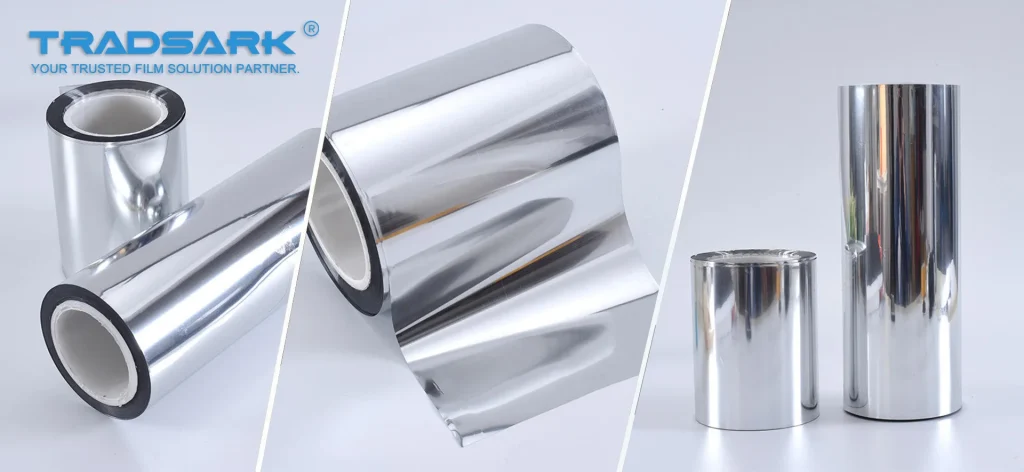

What Is Metalized PE Film / VMPE?

Core Definition

Metalized PE Film / VMPE is created by vaporizing aluminum or other metals in a high-vacuum environment and depositing a nanoscale metal layer on polyethylene film. This process produces a flexible, lightweight film with the barrier performance of metals and the processability of PE.

VMPE films are ideal for applications requiring moisture-proof, oil-resistant, and corrosion-resistant packaging, and for agricultural reflective films that enhance plant growth.

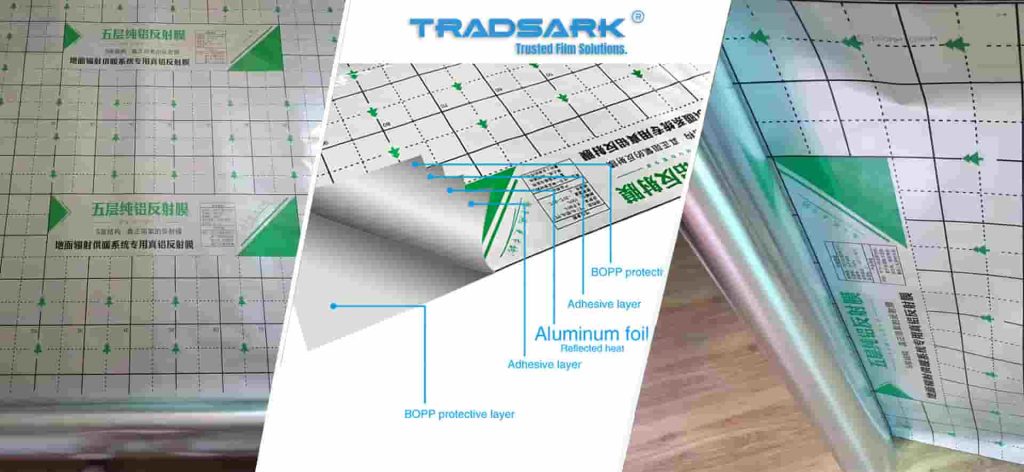

Composition & Structure

-

PE Substrate: Soft, stretchable, and heat-sealable, ensuring excellent flexibility and durability.

-

Metallic Layer: Aluminum or other metals, forming a uniform coating of 0.01–0.1 microns to provide high barrier and reflectivity.

-

Surface Treatment: Corona-treated surfaces improve printing adhesion and allow for matte or glossy finishes suitable for branding.

The synergy of PE flexibility and metal barrier properties ensures that VMPE meets both packaging and agricultural application demands.

Technical Specifications of VMPE Films

Tradsark offers a wide range of customizable options to meet client-specific requirements:

| Hickness | 12mic-50mic | (Common:17/18/20/23/25/30mic) |

| Width | 5cm-270cm | (Common:120/230/250mm) |

| Length | 200m-7000m | (Common:250/300/500/1000/1500m) |

| Color | Clear, silvery | As your request |

| Paper core D/A | 3”/6” | (Common:76/152mm) |

| Packing | 1/6/8 pallets to container | As your request |

Key Advantages of Metalized PE Film / VMPE

High Barrier & Chemical Resistance

-

Blocks oxygen, water vapor, oils, and certain chemicals, making it ideal for high-moisture and high-oil content products.

-

Superior acid and alkali resistance compared to VMCPP films, suitable for food, chemical, and pharmaceutical packaging.

Flexibility & Heat Sealability

-

Soft and highly stretchable PE base prevents cracking or bending damage.

-

Excellent heat-sealing performance allows direct use as a sealing layer in laminated packaging.

Lightweight & Cost-Effective

-

Ultra-thin metal layer makes VMPE 1/5 the weight of traditional aluminum foil.

-

Reduces transportation costs and material usage.

-

Stable PE raw material prices provide cost-effectiveness for large-scale production.

Printing & Branding Compatibility

-

Corona-treated surfaces allow high-speed printing.

-

Matte or glossy finishes can be customized to create premium packaging designs.

-

Enables clear brand visibility for retail and e-commerce products.

Agricultural Benefits (Plant Reflective Film)

-

PE plant reflective films improve fruit ripening and crop yield by reflecting sunlight onto plants.

-

Increases photosynthesis efficiency in apple trees, grape vines, and other crops.

-

Easy to cut, fold, and deploy in greenhouses or outdoor gardens.

Applications of VMPE Films

1. Food Packaging

-

Snacks & Confectionery: Moisture-proof and oil-resistant films for chips, candies, and baked goods.

-

Oily & Salty Foods: Acid/alkali resistance ensures product quality.

-

Frozen Foods & Ready Meals: Barrier properties maintain freshness during storage and transport.

2. Chemical & Pharmaceutical Packaging

-

Protective packaging for sensitive chemical products, solvents, and reactive materials.

-

Excellent barrier properties prevent contamination and degradation.

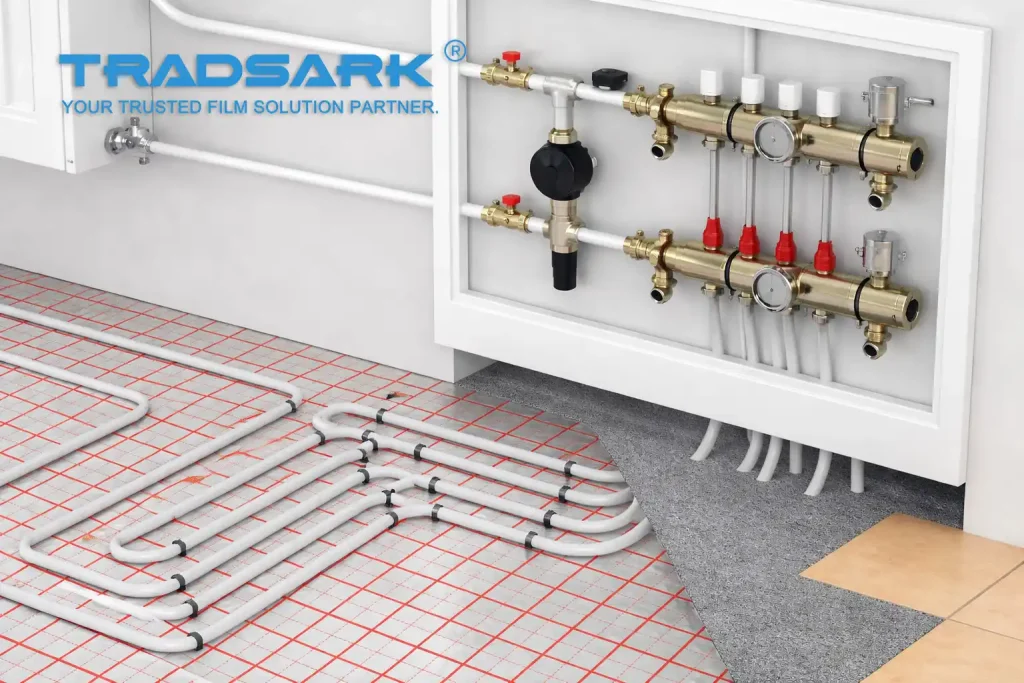

3. Agricultural Reflective Films

-

Enhances sunlight distribution for fruit trees and crops.

-

Improves color, size, and uniformity of fruits.

-

Can be used for greenhouses, orchards, and vegetable cultivation.

4. Industrial & Flexible Packaging

-

Packaging for industrial goods requiring moisture, UV, or chemical resistance.

-

Laminates and multi-layer structures for high-barrier applications.

5. Decorative & Consumer Packaging

-

Shiny or matte metallic finishes enhance product appeal for retail packaging.

-

Suitable for gift wraps, promotional packaging, and luxury items.

How Metalized PE Film / VMPE Is Made

Step 1 – PE Film Preparation

-

Extrusion: PE resin is melted and extruded into a uniform film.

-

Cooling & Stretching: Film is stretched to improve strength and clarity.

-

Surface Cleaning: Film is degreased and dust-free for effective metallization.

Step 2 – Vacuum Metallization

-

Aluminum or other metals are heated in a high-vacuum chamber.

-

Metal vapor is deposited evenly onto the moving PE film.

-

Optional corona or plasma treatment improves adhesion.

Step 3 – Post-Treatment

-

Protective coating can be applied to enhance durability.

-

Film can be laminated with other substrates for multi-functional use.

-

Rolls are slit to desired widths and lengths for shipment.

Advantages Over Other Materials

| Feature | VMPE | Aluminum Foil | VMCPP |

|---|---|---|---|

| Flexibility | Excellent | Low | Good |

| Barrier Properties | High | Very High | Medium |

| Heat Sealability | Yes | No | Yes |

| Weight | Very Light | Heavy | Medium |

| Cost | Lower | High | Medium |

| Agricultural Use | Ideal | Not Suitable | Limited |

VMPE is flexible, lightweight, cost-effective, and environmentally friendly, making it superior for many packaging and agricultural applications.

Market Trends & Sustainability

Eco-Friendly Innovations

-

Increasing use of recyclable PE substrates and environmentally friendly coatings.

-

Focus on sustainable agriculture: reflective films reduce energy usage and improve crop yield.

Industry Growth

-

Rising demand in agriculture, food, chemical packaging, and flexible industrial packaging.

-

Growth in e-commerce packaging requiring lightweight and durable materials.

Technological Advancements

-

Thinner metallic layers reduce material usage while maintaining barrier performance.

-

Integration with smart packaging technologies, like QR codes and anti-counterfeit features.

How to Choose the Right VMPE Film

-

Determine Barrier Needs: High-moisture or oily products need thicker metallic layers.

-

Select Appropriate Thickness: 12–50 μm range based on flexibility and durability requirements.

-

Choose Surface Treatment: Matte or glossy finishes depending on branding and printing needs.

-

Check Regulatory Compliance: Ensure suitability for food, pharmaceutical, or agricultural applications.

-

Evaluate Cost vs Performance: Balance performance requirements with budget and production scale.

Frequently Asked Questions (FAQs)

Can VMPE films be recycled?

Yes. PE films are recyclable, but separation of the metallic layer may require specialized processes.

Is VMPE safe for food contact?

Yes, food-grade VMPE films comply with FDA, EU REACH, or ISO standards for packaging.

Can VMPE films be used outdoors?

Yes, especially for agricultural reflective films, though UV-stabilized versions provide longer durability.

How long do VMPE films maintain their barrier properties?

Under proper storage, packaging films maintain properties for 1–5 years; agricultural films last multiple seasons.

Conclusion

Metalized PE Film / VMPE is a flexible, lightweight, and high-barrier material suitable for packaging, agriculture, chemical protection, and decorative applications. By combining PE flexibility with metallic barrier properties, VMPE films enhance product quality, reduce material usage, and support sustainable practices.

Tradsark provides high-quality, customizable VMPE films with reliable supply and technical support, making us a trusted partner for businesses worldwide. Whether for agriculture, food packaging, or industrial applications, choosing the right VMPE film ensures improved product performance, operational efficiency, and profitability.