What Is Metalized BOPP Film / VMBOPP?

Core Definition & Technology

Metalized BOPP Film / VMBOPP is produced using vacuum metallization, where aluminum is vaporized under a high-vacuum environment and uniformly deposited on the surface of BOPP film. This results in:

-

BOPP Substrate: Provides high tensile strength, clarity, flexibility, and dimensional stability.

-

Aluminum Coating: Offers excellent barrier performance against oxygen, moisture, and UV light.

-

Optional Surface Treatments: Glossy or matte finishes, corona treatment for improved adhesion, and printability.

The combination allows VMBOPP to maintain lightweight design, high barrier properties, and processing versatility—making it ideal for both consumer and industrial packaging applications.

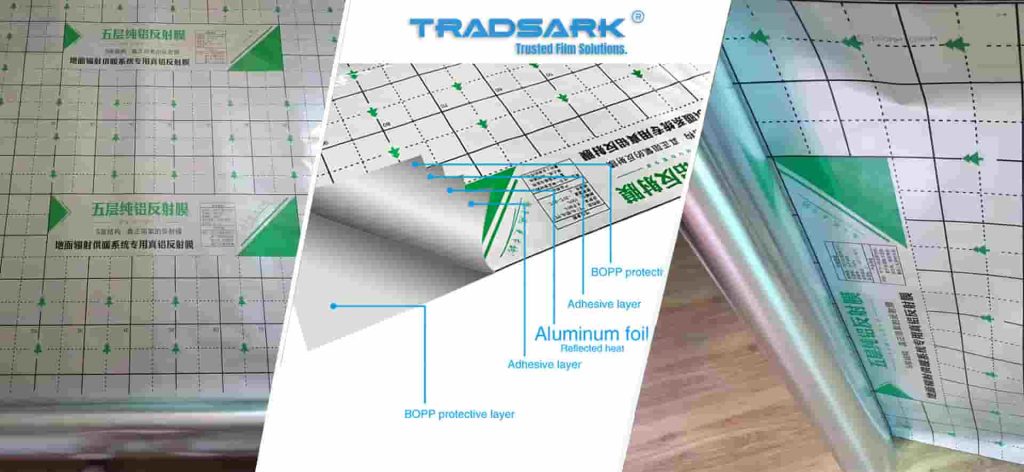

Structure & Composition

VMBOPP is a multilayered material consisting of:

-

BOPP Base Film: Typical thickness ranges from 12–50 μm. Biaxial orientation enhances tensile strength, tear resistance, and heat-sealing performance.

-

Aluminum Layer: Thickness ranges 300–400 Å, providing reflective, barrier, and conductivity properties.

-

Surface Coating (Optional): Acrylic or polyurethane coating improves scratch resistance and print adhesion.

This structure ensures consistent performance, durability, and aesthetic appeal across different applications.

Specifications of Metalized BOPP Film / VMBOPP

Tradsark’s VMBOPP films are available in a wide range of customizable specifications to suit diverse requirements.

| Thickness of film | Thickness of aluminum layer | Width | Diameter | Core size |

| 12-50μm | 300-400Å | ≤2320mm | ≤800mm | 76mm(3″)152mm(6″) |

| Specification :12um,15um,18um,Thickness of Aluminum layer 400A,we can produce on customer’s request. | ||||

| Typical product performance: | ||||

| Item | Unit | Standard value | Test method | |

| Thickness of film | μm | 20 | ASTM D-374 | |

| Tensile Strength | MD | Mpa | 130 | ASTM D-882 |

| TD | 268 | |||

| Elongation | MD | % | 165 | ASTM D-882 |

| TD | 50 | |||

| Heat Shrinkage (120℃,2min) | MD | % | 3.8 | ASTM D-1204 |

| TD | 1.2 | |||

| Heat seal strength | N/15mm | 4.2 | ||

| Wetting Tension | mN/m | 38 | ASTM D-2578 | |

| Friction Coefficient | —— | 0.35 | ASTM D-1894 | |

| Haze | % | 0.9 | ASTM D-1003 | |

| Glossiness | % | – | ASTM D-2457 | |

| Thickness of Aluminum Layer | Å | 380 | ||

| (Square resistance)Ω/sq | 1.53 | GB/T 15717 | ||

| (Optical density )O.D | 1.9 | X•Rite361 | ||

| (Light transmittance)VLT | 1 | ASTM D 1746 | ||

| Equality Tolerance of Metallizing Layer | % | ±10 | GB/T 15717 | |

Key Advantages of Metalized BOPP Film / VMBOPP

High Barrier Performance

-

Blocks oxygen, moisture, and UV light, protecting food, pharmaceuticals, and sensitive consumer goods.

-

Extends product shelf life while maintaining quality and appearance.

-

Reduces packaging material usage compared to traditional aluminum foils.

Cost-Effective & Lightweight

-

Weighs only 1/5 of equivalent aluminum foil.

-

Reduces shipping and material costs by 30–50%.

-

Maintains mechanical and barrier properties with minimal material usage.

Processing Versatility

-

Supports matte and glossy finishes for premium packaging aesthetics.

-

Excellent heat-sealability for automated packaging lines.

-

Compatible with high-speed printing, lamination, and adhesive applications.

Mechanical Strength & Flexibility

-

High tensile strength (MD: 130 MPa, TD: 268 MPa) and elongation ensure durability during handling and processing.

-

Resistant to tearing, punctures, and folding.

-

Maintains structural integrity across packaging operations.

Printing & Branding Compatibility

-

Surface corona treatment improves ink adhesion for flexographic, gravure, or digital printing.

-

Ideal for retail packaging, decorative wraps, and promotional products.

-

Allows high-quality, high-speed printing without compromising barrier performance.

Applications of Metalized BOPP Film / VMBOPP

Food Packaging

-

Snacks, candies, baked goods, and frozen foods benefit from high barrier protection and shelf-life extension.

-

Heat-sealable and flexible for pouches, wrappers, and laminates.

-

Provides premium metallic appearance for retail visibility.

Gift Packaging & Decorative Applications

-

Metallic luster offers a luxurious finish for gift wrapping, labels, and decorative films.

-

Matte or glossy variants allow customization for seasonal promotions and retail branding.

Adhesives & Industrial Uses

-

Used as backing for adhesive tapes, reflective labels, and other industrial films.

-

High barrier and flexibility ensure long-term performance in demanding conditions.

Laminated Film Composites

-

Laminated with PET, CPP, or other substrates for enhanced barrier, strength, and heat seal performance.

-

Widely used in food, pharmaceutical, and cosmetic packaging.

Manufacturing Process of VMBOPP

Step 1 – BOPP Film Preparation

-

Extrusion and Orientation: Produces biaxially oriented film with uniform thickness and high tensile strength.

-

Surface Cleaning: Removes dust and contaminants for uniform metallization.

Step 2 – Vacuum Metallization

-

Aluminum is vaporized in a high-vacuum chamber.

-

Metal condenses on BOPP film forming a thin, uniform layer.

-

Optional corona or plasma treatments enhance adhesion.

Step 3 – Post-Treatment & Finishing

-

Protective coatings improve scratch resistance and printability.

-

Slitting and rewinding for customized roll widths and lengths.

-

Surface treatments applied for high-speed printing and lamination.

Comparison With Other Packaging Materials

| Feature | VMBOPP | Aluminum Foil | Metallized PET |

|---|---|---|---|

| Flexibility | High | Low | Medium |

| Barrier | High | Very High | High |

| Heat Sealability | Yes | No | Limited |

| Lightweight | Yes | No | Yes |

| Cost | Low | High | Medium |

| Printing & Branding | Excellent | Limited | Good |

VMBOPP provides a cost-effective, flexible, and high-performance solution for a wide range of packaging applications.

Market Trends & Sustainability

Eco-Friendly Innovations

-

Lightweight design reduces carbon footprint in transport.

-

Aluminum and BOPP layers can be recycled where facilities exist.

-

Supports sustainable packaging initiatives in food, pharma, and cosmetics.

Growing Flexible Packaging Industry

-

Demand in snack, confectionery, and beverage sectors continues to rise.

-

E-commerce growth drives the need for lightweight, durable, and visually appealing packaging.

Technological Advancements

-

Thinner aluminum layers reduce material usage without compromising barrier performance.

-

Advanced corona treatments improve printability and lamination performance.

-

Development of multi-functional films including anti-counterfeit and smart packaging.

How to Choose the Right VMBOPP Film

-

Barrier Requirements: Determine oxygen, moisture, and UV protection needed.

-

Film Thickness: Standard 12–50 μm based on application. Thicker films for industrial use, thinner for consumer packaging.

-

Surface Finish: Glossy or matte for branding and print aesthetics.

-

Lamination Compatibility: Ensure adhesion with PET, CPP, or other substrates.

-

Regulatory Compliance: Food-grade, pharmaceutical, or industrial-safe certifications as required.

Frequently Asked Questions (FAQs)

Is VMBOPP recyclable?

Yes, the BOPP substrate can be recycled, though separation of the aluminum layer may require specialized processes.

Can VMBOPP be used in food packaging?

Yes, it can meet FDA, EU REACH, and ISO standards for food-safe applications.

How durable is VMBOPP?

VMBOPP maintains barrier and mechanical properties for 1–5 years depending on storage and environmental conditions.

Can VMBOPP be laminated with other films?

Yes, commonly laminated with PET, CPP, or paper to enhance barrier and mechanical properties.

Conclusion

Metalized BOPP Film / VMBOPP is a versatile, high-performance packaging material that combines lightweight, flexibility, barrier protection, and aesthetic appeal. It is widely used across food, gift packaging, adhesives, and laminated film applications.

Tradsark provides customized VMBOPP films with tailored specifications to meet unique industry requirements. Choosing the right VMBOPP solution can enhance product shelf life, reduce costs, improve branding, and support sustainable packaging initiatives.