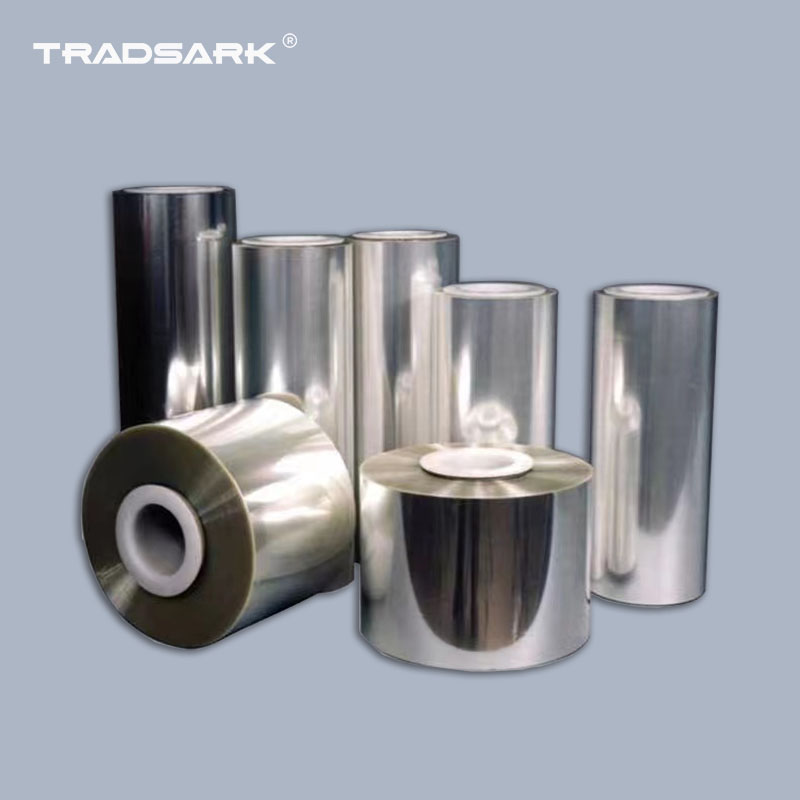

What Is Metalized CPP Film / VMCPP?

Core Definition & Technology

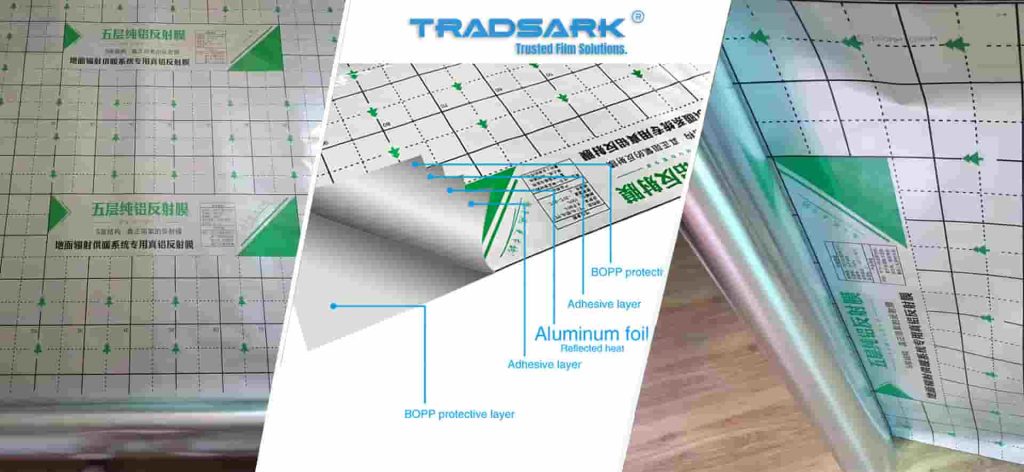

Metalized CPP Film / VMCPP is produced through a vacuum metallization process, where aluminum or other metals are heated to vaporize in a high-vacuum chamber. The metal vapor uniformly deposits on the surface of a CPP film, forming a nanoscale metallic layer. This unique process imparts the film with dual properties:

-

CPP substrate: Flexible, tear-resistant, heat-sealable, and easy to process.

-

Metallic layer: Provides excellent barrier properties, reflectivity, thermal conductivity, and aesthetic metallic finish.

The combination of plastic and metal characteristics makes VMCPP an ideal choice for flexible packaging where both mechanical strength and barrier performance are required.

Composition & Structure

VMCPP’s structure consists of:

-

CPP Base Film: Provides high tensile strength, elongation, and flexibility. Common thickness ranges from 18–30 μm.

-

Metallic Aluminum Layer: Typically 350–380 Å thick, offering oxygen and moisture barrier protection.

-

Optional Surface Treatments: Corona-treated surfaces improve adhesion for printing, lamination, and coating applications.

The synergy of CPP and the metallic layer ensures VMCPP meets high-performance standards for both industrial and consumer packaging.

Specifications of Metalized CPP Film / VMCPP

Tradsark provides VMCPP films with customizable specifications to suit various applications:

| Thickness of film | Thickness of aluminum layer | Width | Diameter | Core size |

| 18,20,25,30μm | 350-380Å | ≤2320mm | ≤800mm | 76mm(3″)152mm(6″) |

| Typical product performance: | ||||

| Item | Unit | Standard value | Test method | |

| Thickness of film | μm | 25 | ASTM D-374 | |

| Tensile Strength | MD | Mpa | 54 | ASTM D-882 |

| TD | 33 | |||

| Elongation | MD | % | 565 | ASTM D-882 |

| TD | 612 | |||

| Heat seal strength | N/15mm | 11.2 | ASTM D-882 | |

| Wetting Tension | mN/m | 38 | ASTM D-2578 | |

| Friction Coefficient | —— | 0.62 | ASTM D-1894 | |

| Haze | % | 2.7 | ASTM D-1003 | |

| Glossiness | % | – | ASTM D-2457 | |

| Thickness of Aluminum Layer | Å | 380 | ||

| (Square resistance)Ω/sq | 2.7 | GB/T 15717 | ||

| (Optical density )O.D | 1.9 | X•Rite361 | ||

| (Light transmittance)VLT | 1 | ASTM D 1746 | ||

| Equality Tolerance of Metallizing Layer | % | ±10 | GB/T 15717 | |

| Combining Fastness Tolerance of Metallizing Layer | % | Aluminum fall off ﹤2 | 3M adhesive tape | |

| Moisture vapor transmission rate | g/m2•24hr | 0.5 | ASTM E96 | |

| Oxygen transmission rat(23℃,0%RH) | cm3/m2•1atm•24hr | 45 | ASTM D1434 | |

Key Advantages of Metalized CPP Film / VMCPP

Superior Adhesion & Lamination

-

Excellent bonding to other films such as BOPP or PET for laminated structures.

-

Uniform aluminum layer ensures consistent barrier properties across the film.

-

Strong adhesion allows VMCPP to withstand the stresses of printing, cutting, and packaging.

Heat Sealability

-

CPP substrate provides excellent heat-sealing properties.

-

VMCPP can be directly used as a sealing layer in flexible packaging.

-

Ensures secure packaging for food, pharmaceuticals, and other sensitive products.

Barrier Properties

-

Ultra-thin aluminum layer provides high resistance to oxygen, moisture, and light.

-

Protects food, chemical, and pharmaceutical products from degradation.

-

Reduces spoilage and extends shelf life.

Mechanical Strength & Flexibility

-

CPP base allows high elongation (565–612%) and tensile strength (MD: 54 MPa, TD: 33 MPa).

-

Resists tearing, puncturing, and folding during processing and transportation.

-

Suitable for bag making, pouches, laminates, and industrial flexible packaging.

Lightweight & Cost-Effective

-

VMCPP is significantly lighter than aluminum foil composites.

-

Reduces shipping costs and environmental footprint.

-

Lower material cost while maintaining barrier performance.

Printing & Branding Compatibility

-

Surface corona treatment allows high-speed printing with excellent ink adhesion.

-

Supports matte, glossy, or metallic finishes for premium packaging.

-

Enables strong brand visibility for retail products.

Applications of Metalized CPP Film / VMCPP

Flexible Packaging Industry

-

Food Packaging: Snacks, candies, baked goods, frozen foods, and ready-to-eat meals.

-

Pharmaceutical Packaging: Blister packs, sachets, and medical device packaging.

-

Beverage Packaging: Laminates for coffee, tea, and powdered drinks.

Bag Making & Laminated Films

-

Lamination with BOPP or PET enhances barrier, strength, and heat-sealing performance.

-

Ideal for multi-layer composite packaging used in high-barrier applications.

Industrial Packaging

-

Protective wrapping for electronic components, adhesives, and industrial chemicals.

-

High barrier prevents moisture and oxygen exposure during storage and shipping.

Decorative & Consumer Packaging

-

Metallic finish creates premium appearance for gift packaging, retail products, and promotional items.

-

Supports both functional and aesthetic requirements in consumer goods.

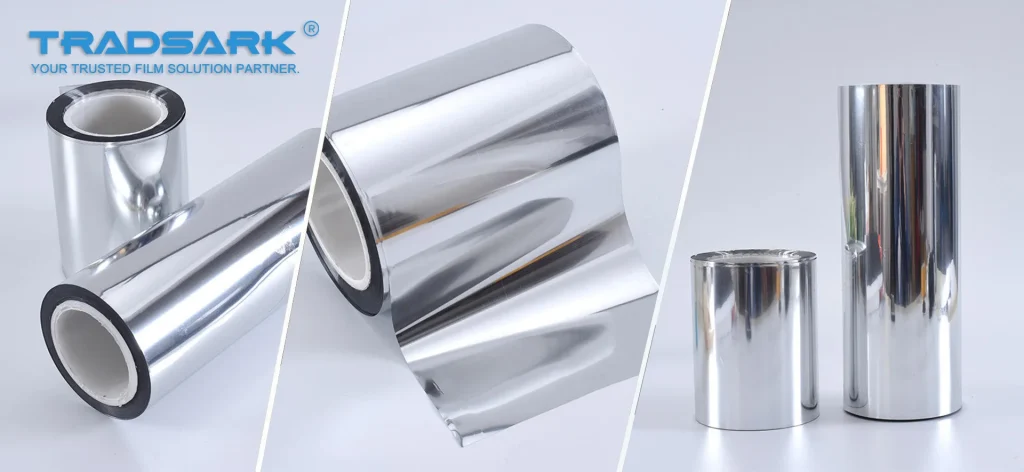

Manufacturing Process of VMCPP

Step 1 – CPP Film Preparation

-

Extrusion of CPP Film: Produces uniform film thickness with precise control over mechanical properties.

-

Orientation & Stretching: Ensures high tensile strength, clarity, and flexibility.

-

Surface Cleaning: Removes contaminants to ensure uniform metallization.

Step 2 – Vacuum Metallization

-

Aluminum is heated to vaporize in a high-vacuum chamber.

-

Metal vapor condenses onto the CPP film, forming a thin, uniform layer.

-

Optional plasma or corona treatment enhances adhesion.

Step 3 – Post-Treatment & Finishing

-

Rolls can be coated with protective layers to enhance scratch resistance.

-

Slitting and rewinding to specific widths and lengths for shipment.

-

Surface treatments applied for improved printing and lamination.

Comparison With Other Packaging Films

| Feature | VMCPP | Aluminum Foil | VMPE |

|---|---|---|---|

| Flexibility | High | Low | Medium |

| Barrier Properties | High | Very High | Medium |

| Heat Sealability | Yes | No | Yes |

| Lightweight | Yes | No | Yes |

| Cost | Low | High | Medium |

| Printing & Branding | Excellent | Limited | Good |

VMCPP provides a cost-effective, flexible, high-barrier solution that is superior for laminated and flexible packaging applications.

Market Trends & Sustainability

Eco-Friendly Solutions

-

Use of recyclable CPP and aluminum layers for environmentally responsible packaging.

-

Lightweight design reduces carbon footprint in logistics.

-

Supports sustainable packaging initiatives in food, pharmaceuticals, and agriculture.

Growth in Flexible Packaging

-

Increasing demand in snacks, pharmaceuticals, and industrial packaging sectors.

-

E-commerce growth drives need for lightweight, durable, and visually appealing packaging.

Technological Advancements

-

Improved vacuum metallization technology allows thinner aluminum layers with consistent quality.

-

Enhanced printing compatibility and lamination capabilities.

-

Development of anti-counterfeit, smart packaging, and multi-functional films.

How to Choose the Right Metalized CPP Film / VMCPP

-

Assess Barrier Requirements: Consider oxygen, moisture, and light protection needed.

-

Determine Thickness: 18–30 μm based on application. Thicker films for industrial use; thinner for consumer packaging.

-

Surface Treatment: Matte or glossy finishes for printing and branding.

-

Check Compatibility for Lamination: Ensure adhesion with BOPP, PET, or other substrates.

-

Regulatory Compliance: Food-grade, pharmaceutical, or chemical-safe standards.

Frequently Asked Questions (FAQs)

Is VMCPP recyclable?

Yes, CPP films can be recycled, though separation of the aluminum layer may require specialized processes.

Can VMCPP films be used for food packaging?

Yes, VMCPP can be produced as food-grade compliant material per FDA, EU REACH, or ISO standards.

How durable is VMCPP?

VMCPP maintains barrier and mechanical properties for 1–5 years depending on storage and application conditions.

Can VMCPP be laminated with other films?

Yes, it is commonly laminated with BOPP, PET, or paper to enhance barrier and mechanical properties for flexible packaging.

Conclusion

Metalized CPP Film / VMCPP is a versatile, high-performance material suitable for flexible packaging, laminated films, bag making, industrial packaging, and decorative applications. Its combination of CPP flexibility and metallic barrier properties ensures high durability, excellent barrier performance, heat-sealability, and aesthetic appeal.

Tradsark provides customizable VMCPP films for a wide range of applications, offering high-quality products with technical support and reliable supply. By selecting the right VMCPP specifications, businesses can improve product shelf life, reduce costs, enhance branding, and adopt more sustainable packaging solutions.