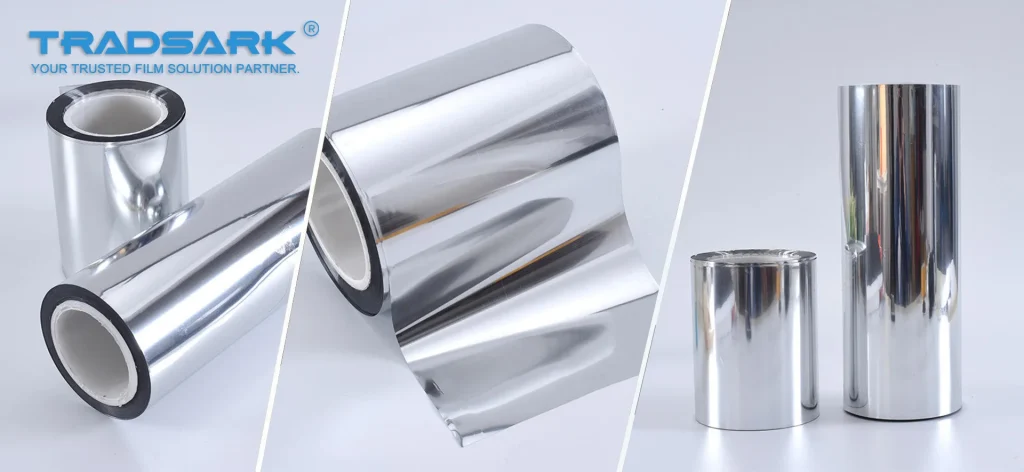

What Is Metallized PET Film / VMPET?

Definition and Core Technology

Metallized PET Film, also called VMPET, is manufactured by vacuum depositing a thin metal layer onto PET film. Aluminum is the most common metal due to its affordability, excellent barrier properties, and reflectivity. The vacuum metallization process ensures:

-

PET Substrate: Provides dimensional stability, high tensile strength, and durability. Thickness ranges typically from 5–50 microns.

-

Metallized Layer: Extremely thin aluminum coating provides oxygen, moisture, and UV protection, along with metallic gloss.

-

Optional Coatings: Enhance printability, heat sealability, or matte/gloss finishes according to application needs.

The process results in a lightweight yet highly functional material suitable for high-speed production lines and diverse packaging formats.

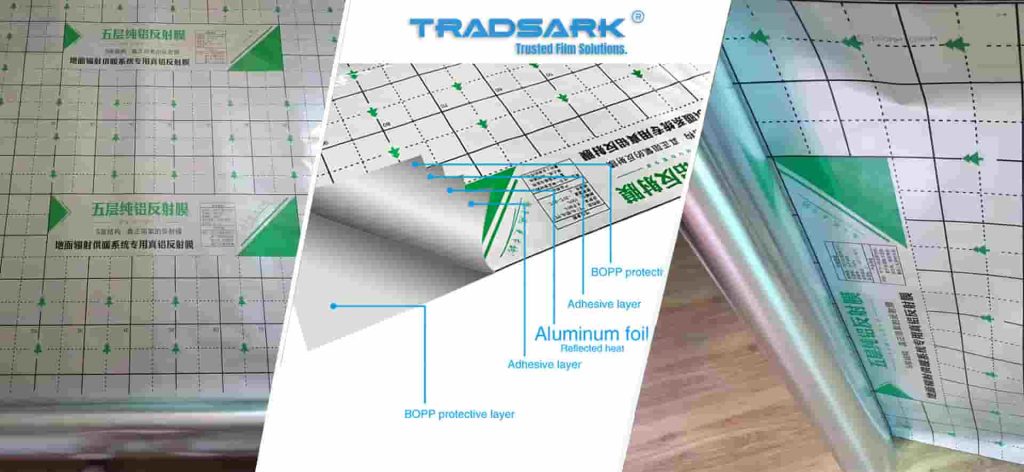

Structure & Composition

VMPET’s structure includes three main layers:

-

PET Film Base (5–50 microns): Acts as the backbone, giving mechanical strength and tear resistance.

-

Aluminum Coating (0.01–0.1 micron): Provides barrier properties and metallic shine, which can be adjusted to matte if desired.

-

Surface Treatment Layer (Optional): Corona or acrylic coatings enhance adhesion for printing, laminating, or hot stamping.

This combination offers a high-performance alternative to plain plastic films while maintaining lightweight, flexibility, and cost-efficiency.

Technical Specifications of Metallized PET Film / VMPET

Tradsark offers VMPET films in a wide range of customizable sizes, thicknesses, and properties to meet specific industrial requirements.

| Material | PET, MPET, VMPET, Polyethylene terephthalate |

| Reflectivity | Up to 95% |

| Emissivity | Up to E0.05 |

| Optical Density(OD) | 1.62~3.6, customizable |

| Corona Treatment | 40-50 dyne, customizable |

| Permeability O2 TR | <15.0 cm3/(m2•24h•0.1MPa) |

| Permeability WVTR | <3.5 g /(m2•24h) |

| Width | 1m, 1.2m, 1.5m, 1.8m, 2m, 2.6m, customizable |

| Length | 1000m~36000m per roll, customizable |

Custom options include roll widths, thicknesses, aluminum coating thickness, surface finishes, and corona treatment levels for specific industrial applications.

Advantages of Metallized PET Film / VMPET

H3: Excellent Barrier Performance

-

Protects products from oxygen, moisture, and UV light, extending shelf life of food, pharmaceuticals, and chemicals.

-

Provides moderate barrier properties compared to aluminum foil at a lower cost.

-

Maintains product quality in long-term storage and during transportation.

Lightweight and Cost-Effective

-

VMPET is significantly lighter than aluminum foil, reducing shipping costs and material usage.

-

Aluminum coating uses only a fraction of the metal required for foil, lowering production costs.

-

PET substrate provides strength without adding bulk.

Versatility in Processing

-

Compatible with high-speed laminating, printing, and hot stamping.

-

Can be combined with PE, CPP, BOPP, or other substrates for laminated packaging films.

-

Available in glossy or matte finishes, enhancing visual appeal for retail packaging.

Mechanical Strength & Flexibility

-

PET film base ensures high tensile strength, tear resistance, and dimensional stability.

-

Flexible enough to withstand folding, bending, or heat-sealing operations without cracking.

-

Suitable for complex packaging formats including pouches, sachets, and wrappers.

Printing & Branding Capability

-

Corona-treated surface ensures excellent ink adhesion for flexographic, gravure, or digital printing.

-

Ideal for decorative packaging, labels, and promotional films.

-

Metallic gloss enhances brand perception and retail visibility.

Applications of Metallized PET Film / VMPET

Food Packaging

-

Snack pouches, coffee bags, frozen food wrappers, vacuum-sealed meat, and pet food packaging.

-

Barrier properties protect freshness, aroma, and taste.

-

Provides metallic sheen for premium packaging appearance.

Electronics Industry

-

Antistatic packaging for microchips, circuit boards, LEDs, and other sensitive components.

-

Protects electronic components from electrostatic discharge (ESD) and environmental factors.

Printing & Decorative Applications

-

Labels, hot stamping, and laminates for cosmetics, gift packaging, and decorative films.

-

Can be used for silver and gold metallic paper applications, offering luxury aesthetics.

Pharmaceutical and Medical Packaging

-

Blister packs, sachets, and sterilized medical packaging.

-

High barrier ensures drug stability and moisture resistance.

Industrial and Chemical Packaging

-

Packaging for pesticides, chemicals, and rescue supplies.

-

Aluminum coating enhances resistance to oils, acids, and moisture.

Manufacturing Process of VMPET

Step 1 – PET Film Preparation

-

Extrusion: PET resin is melted and extruded into a thin film.

-

Biaxial Orientation: Stretching in machine and transverse directions improves tensile strength and clarity.

-

Cleaning: Dust, oil, and other contaminants removed to ensure uniform metal deposition.

Step 2 – Vacuum Metallization

-

PET film passes through a high-vacuum chamber (10⁻⁴ – 10⁻⁶ Torr).

-

Aluminum wire or pellets are evaporated under vacuum and deposited on PET film.

-

Uniform thin layer of aluminum (0.01–0.1 micron) is achieved, providing barrier and reflective properties.

Step 3 – Post-Treatment

-

Optional Coatings: Acrylic or polymer coatings improve scratch resistance, printability, and adhesion.

-

Slitting & Rewinding: Finished film is cut to custom widths and lengths.

-

Quality Inspection: Ensures barrier performance, gloss, reflectivity, and thickness uniformity.

Advantages Over Traditional Packaging Materials

| Feature | VMPET | Aluminum Foil | Plain PET |

|---|---|---|---|

| Weight | Lightweight | Heavy | Lightweight |

| Barrier | Moderate | High | Low |

| Flexibility | High | Low | High |

| Printability | Excellent | Limited | Good |

| Cost | Moderate | High | Low |

| Heat Sealability | Yes | No | Limited |

VMPET combines the strength of PET with metallic barrier properties, offering a cost-effective, flexible alternative to traditional aluminum or plastic films.

Market Trends & Sustainability

Growing Demand for Flexible Packaging

-

Increased demand in snacks, beverages, cosmetics, and pharmaceuticals.

-

E-commerce growth drives the need for lightweight, durable, and attractive packaging.

Eco-Friendly Innovations

-

Lighter films reduce carbon footprint during transport.

-

Aluminum layer can be recycled, though specialized facilities may be required.

-

Supports sustainable packaging initiatives by minimizing material usage.

Technological Advancements

-

Development of ultra-thin aluminum layers reduces material usage without sacrificing barrier performance.

-

Advanced corona and surface treatments improve lamination, printing, and heat seal properties.

-

Integration of smart packaging features such as QR codes, RFID, and anti-counterfeit printing.

How to Choose the Right Metallized PET Film / VMPET

-

Barrier Requirements: Choose appropriate aluminum thickness for oxygen/moisture protection.

-

Film Thickness: 6–125 micron based on application; thicker films for industrial use, thinner for retail packaging.

-

Surface Finish: Glossy or matte for aesthetic purposes.

-

Lamination Compatibility: Ensure compatibility with PE, CPP, BOPP, or other substrates.

-

Regulatory Compliance: Food-grade, medical-grade, or industrial-grade certifications as required.

Frequently Asked Questions (FAQs)

Is Metallized PET Film recyclable?

Yes. PET substrate is recyclable, though separation of aluminum layer may require specialized processes.

Can VMPET be used for food packaging?

Yes. Meets FDA, EU REACH, and ISO standards for food-safe applications.

How long can VMPET maintain barrier properties?

Typically 1–5 years depending on storage conditions and application environment.

Can VMPET be laminated?

Yes. Commonly laminated with PE, CPP, BOPP, or paper to enhance mechanical and barrier performance.

Conclusion

Metallized PET Film / VMPET is a versatile, high-performance material suitable for food, pharmaceutical, electronics, printing, decoration, and industrial applications. Its lightweight, flexible, high-barrier, and visually appealing properties make it a preferred choice for modern packaging and industrial solutions.

Tradsark offers customizable VMPET films to meet specific requirements in thickness, width, roll length, aluminum coating, and surface finish. By selecting the right VMPET solution, businesses can extend product shelf life, reduce packaging costs, enhance brand appearance, and support sustainability initiatives.