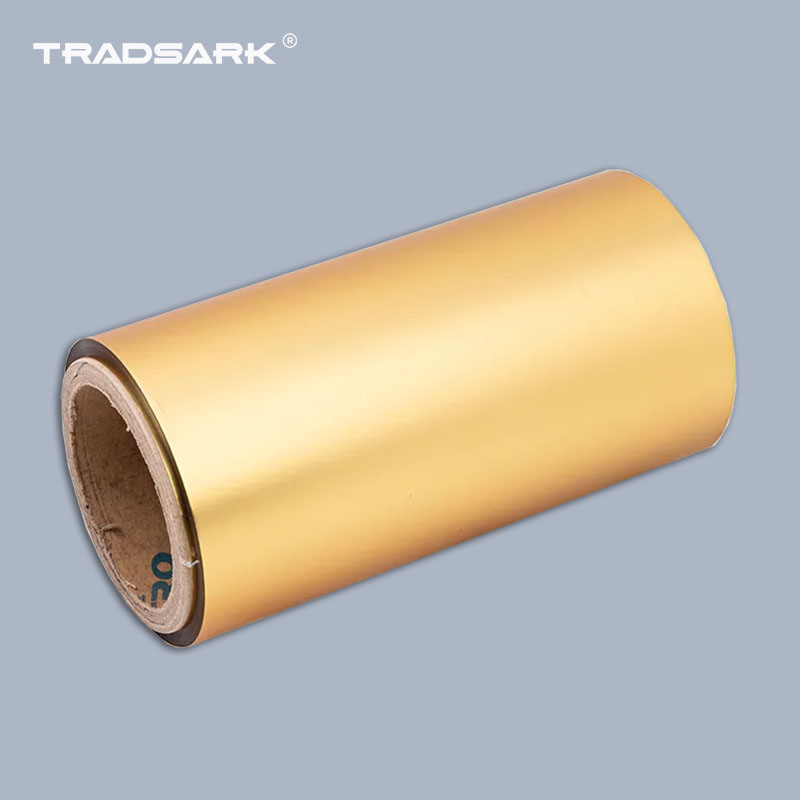

Technical Specifications of Matt Metallized Film

Tradsark provides customizable Matt Metallized Film to meet specific client requirements. Typical specifications include:

| Thickness of film | Thickness of aluminum layer | Width | Diameter | Core size |

| 12-50μm | 300-400Å | ≤2320mm | ≤800mm | 76mm(3″)152mm(6″) |

| Specification :12um,15um,18um,Thickness of Aluminum layer 400A,we can produce on customer’s request. | ||||

| Typical product performance: | ||||

| Item | Unit | Standard value | Test method | |

| Thickness of film | μm | 20 | ASTM D-374 | |

| Tensile Strength | MD | Mpa | 130 | ASTM D-882 |

| TD | 268 | |||

| Elongation | MD | % | 165 | ASTM D-882 |

| TD | 50 | |||

| Heat Shrinkage (120℃,2min) | MD | % | 3.8 | ASTM D-1204 |

| TD | 1.2 | |||

| Heat seal strength | N/15mm | 4.2 | ||

| Wetting Tension | mN/m | 38 | ASTM D-2578 | |

| Friction Coefficient | —— | 0.35 | ASTM D-1894 | |

| Haze | % | 0.9 | ASTM D-1003 | |

| Glossiness | % | – | ASTM D-2457 | |

| Thickness of Aluminum Layer | Å | 380 | ||

| (Square resistance)Ω/sq | 1.53 | GB/T 15717 | ||

| (Optical density )O.D | 1.9 | X•Rite361 | ||

| (Light transmittance)VLT | 1 | ASTM D 1746 | ||

| Equality Tolerance of Metallizing Layer | % | ±10 | GB/T 15717 | |

Advantages of Matt Metallized Film

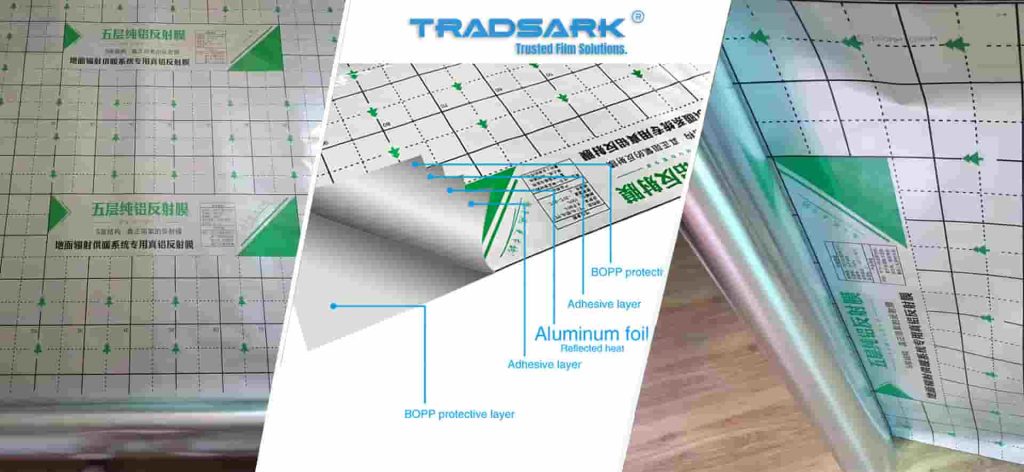

Superior Barrier Properties

The metallic layer of matt metallized films offers an effective barrier against environmental factors, making it ideal for packaging sensitive products. It protects against:

-

Oxygen and Moisture: Reduces oxygen transmission and water vapor penetration, extending the shelf life of food and pharmaceuticals.

-

UV Light: Blocks up to 99% of harmful UV rays, preventing product degradation and discoloration.

Premium Aesthetic Appeal

-

Matte Finish: Provides a soft, non-glare surface that enhances the look of packaging, labels, and decorative products.

-

High Printability: Supports flexographic, gravure, and digital printing, allowing for vibrant, high-quality designs.

Durability and Flexibility

-

Lightweight Yet Strong: Combines the mechanical strength of PET or BOPP with metalized barrier protection.

-

Flexible Forming: Can be laminated, folded, or shaped without cracking, ideal for pouches, wrappers, and gift packaging.

Sustainability

-

Recyclable: PET and BOPP substrates can be recovered using specialized recycling techniques.

-

Reduced Metal Use: Ultra-thin aluminum layer minimizes material consumption while maintaining barrier efficiency.

Applications of Matt Metallized Film

Packaging Industry

-

Food Packaging: Snacks, confectionery, coffee bags, frozen foods, and vacuum-sealed products. The matte metallic surface preserves freshness while offering a premium look.

-

Pharmaceutical Packaging: Protects medicines from moisture, oxygen, and UV exposure.

-

Gift and Cosmetic Packaging: Provides a luxurious, non-glare appearance that enhances brand perception.

Labeling and Printing

-

Durable labels for beverages, cosmetics, electronics, and industrial products.

-

Excellent adhesion for inks and coatings ensures long-lasting prints.

Adhesive Tapes and Laminates

-

Backing for reflective and decorative tapes.

-

High dimensional stability and heat resistance support industrial applications.

Decorative and Industrial Uses

-

Wall decals, decorative films, and signage.

-

Protective films in electronics and automotive components.

Why Choose Tradsark Matt Metallized Film?

At Tradsark, we are committed to delivering high-quality Metalized PET Film / Aluminized Polyester Film that meets the highest industry standards:

-

Customizable Specifications: Thickness, width, and aluminum layer can be tailored to your requirements.

-

Advanced Production Facilities: Equipped with modern vacuum metallization and coating lines for consistent quality.

-

Technical Expertise: Decades of experience in metallized films for packaging, electronics, and decorative applications.

-

Global Supply: Reliable delivery to international markets with strong B2B support.

-

Sustainability Focus: Efforts in recyclable PET substrates and environmentally friendly coatings.

How to Select the Right Matt Metallized Film

When choosing a matt metallized film for your application, consider:

-

Barrier Needs: Higher aluminum thickness for maximum oxygen and moisture protection.

-

Print Requirements: Ensure compatibility with inks and coatings.

-

Film Thickness: Thicker films for industrial uses; thinner films for flexible packaging.

-

Application Environment: Heat, humidity, or light exposure may influence choice.

-

Budget vs Performance: Balance quality and cost-effectiveness for your target market.

Trends in Matt Metallized Film Industry

Sustainability and Green Packaging

-

Increased use of recycled PET (rPET) and bio-based substrates.

-

Water-based matte coatings replacing solvent-based options to reduce VOC emissions.

Advanced Functionalities

-

Antimicrobial and UV-stable coatings for high-demand applications.

-

Anti-static properties for electronics packaging.

Customized & Smart Packaging

-

QR codes, RFID tags, and interactive designs integrated into metallized films.

-

Trend towards premium, decorative matte finishes in luxury packaging.

Frequently Asked Questions (FAQs)

Can Matt Metallized Film be recycled?

Yes, specialized recycling processes can separate aluminum from PET/BOPP substrates for reuse.

Is it food-safe?

Yes, Tradsark offers food-grade variants compliant with FDA, EU REACH, and ISO standards.

Can it be heat-sealed?

Yes, when laminated with heat-sealable films like PE or PP.

How durable is the matte finish?

The matte coating provides scratch resistance while maintaining the metal layer’s barrier properties.

Conclusion

Matt Metallized Film from Tradsark offers an ideal combination of aesthetics, functionality, and sustainability. With superior barrier performance, flexibility, and high printability, it is an indispensable solution for packaging, labeling, decorative, and industrial applications. By choosing Tradsark, customers gain a reliable partner for Metalized PET Film / Aluminized Polyester Film, ensuring consistent quality, customization options, and global supply.