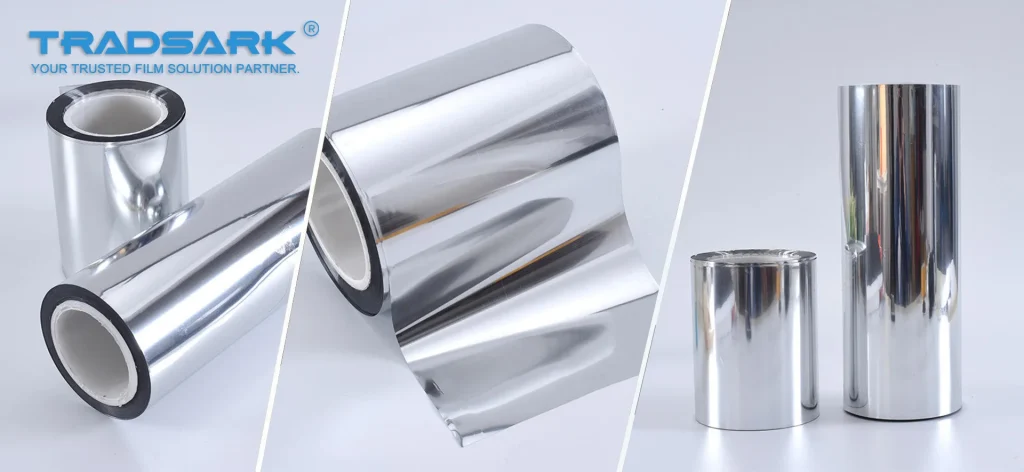

What Is Color Metallized Film?

Definition and Core Technology

Color Metallized Film is a multi-layered composite that integrates the reflective qualities of metals with the visual appeal of colored coatings. The process involves:

-

Vacuum Metallization: Aluminum or other metals are evaporated in a high-vacuum chamber and deposited on the plastic substrate, forming a layer only 0.01–0.1 micron thick.

-

Color Coating: A layer or multiple layers of color are applied through coating, printing, or dyeing, allowing a wide range of vibrant colors.

-

Optional Surface Treatments: Corona or plasma treatments improve adhesion, printability, and lamination compatibility.

This combination results in a film that offers metallic shine, rich colors, barrier performance, and flexibility, suitable for modern packaging and decorative applications.

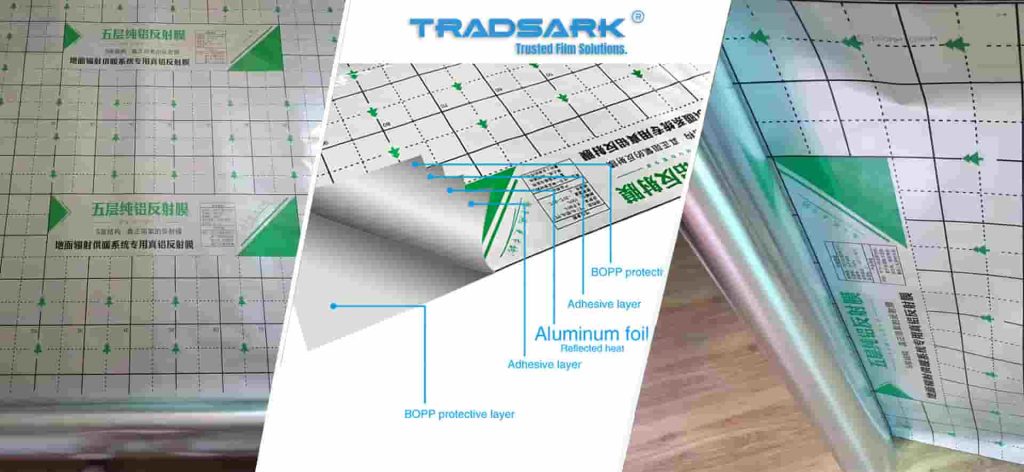

Structure & Composition

Color Metallized Film typically has the following structure:

-

Plastic Substrate (BOPP, PE, PET): Provides tensile strength, durability, and flexibility. Thickness ranges from 6–125 microns.

-

Metal Layer (Al, Cu, Zn, or Alloy, 0.01–0.1 micron): Offers reflectivity, barrier properties, and metallic luster.

-

Color Coating Layer(s): Impart vivid colors, matte/gloss finishes, and decorative appeal.

-

Optional Protective Coating: Enhances scratch resistance, heat sealability, and print adhesion.

Technical Specifications of Color Metallized Film

Tradsark offers customizable Color Metallized Films to meet diverse industrial and decorative requirements.

| Property | Specification | Notes |

|---|---|---|

| Thickness | 6–125 micron | Standard: 6, 7, 8, 10, 12, 15, 19, 25 micron |

| Width | 5mm – 2540mm | Custom widths available |

| Roll Length | 1,000–50,000 m | Customizable per order |

| Max Roll Diameter | 800 mm | Standard |

| Material | PET, MPET, VMPET, BOPP, PE | Food-grade or industrial-grade options |

| Reflectivity | Up to 95% | Adjustable |

| Emissivity | Up to E0.05 | |

| Optical Density (OD) | 1.62–3.6 | Customizable |

| Corona Treatment | 40–50 dyne | Enhances print adhesion |

| O2 Transmission Rate | <15.0 cm³/(m²·24h·0.1MPa) | High barrier |

| Water Vapor Transmission Rate | <3.5 g/(m²·24h) | Moisture protection |

Advantages of Color Metallized Film

Exceptional Barrier Properties

-

Protects packaged products from oxygen, moisture, and UV light, extending shelf life of food, pharmaceuticals, and sensitive chemicals.

-

Provides acid, alkali, and oil resistance, making it suitable for high-oil or corrosive products.

-

Barrier performance can be enhanced by laminating with other films like PE or BOPP.

Vibrant and Customizable Appearance

-

Combines metallic sheen with vivid colors, customizable to brand requirements.

-

Supports glossy, matte, metallic, or pearlescent finishes.

-

Ideal for premium packaging, decorative films, and labels.

Lightweight and Cost-Effective

-

Uses minimal metal, significantly lighter than aluminum foil while maintaining reflectivity and barrier performance.

-

Reduces transportation costs and packaging material usage.

-

Lower production cost compared to multi-layer foil composites.

Flexibility and Mechanical Strength

-

Substrate ensures high tensile strength, tear resistance, and foldability.

-

Can be used in complex packaging formats like pouches, sachets, wrappers, and laminated products.

-

Withstands high-speed processing lines without cracking or delamination.

Printability and Lamination

-

Corona-treated surface allows high-speed printing and ink adhesion.

-

Compatible with lamination on PE, PET, BOPP, or paper to improve mechanical and barrier performance.

-

Suitable for hot stamping, embossing, or digital printing, enhancing visual appeal.

Applications of Color Metallized Film

Food Packaging

-

Snack packaging (chips, cookies, confectionery)

-

Coffee bags and tea wrappers

-

Frozen food packaging and vacuum-sealed meat bags

Barrier properties preserve freshness, while metallic colors enhance product visibility and appeal.

Cosmetics and Personal Care Packaging

-

Lipstick tubes, facial mask sachets, hair care product packaging

-

Provides premium metallic finish with brand-consistent colors

Pharmaceutical and Medical Packaging

-

Blister packs, sachets, and medical device wraps

-

Protects drugs and medical supplies from moisture, oxygen, and UV degradation

Decorative and Printing Applications

-

Labels, gift wraps, and premium packaging

-

Promotional materials and decorative films for holiday or special occasions

-

Supports hot stamping and digital printing for luxury appearance

Industrial and Electronic Applications

-

Packaging for electronics, chemicals, and industrial products

-

Offers antistatic, reflective, and barrier properties for sensitive applications

Manufacturing Process of Color Metallized Film

Step 1 – Substrate Preparation

-

Extrusion and Orientation: PET, BOPP, or PE is extruded and oriented biaxially to improve strength and dimensional stability.

-

Cleaning: Ensures removal of dust, grease, and debris for uniform metallization.

Step 2 – Vacuum Metallization

-

Film enters a high-vacuum chamber, removing air to prevent oxidation.

-

Aluminum or other metals are evaporated and deposited as an ultra-thin layer on the substrate.

-

Produces a uniform reflective metallic layer with high adhesion.

Step 3 – Color Coating

-

Coating, printing, or dyeing applies vibrant colors.

-

Can include multiple layers for enhanced opacity or decorative effects.

-

Optional protective coating improves scratch resistance and print adhesion.

Step 4 – Finishing and Quality Control

-

Slitting and rewinding to custom widths and lengths

-

Inspection for reflectivity, color uniformity, barrier performance, and mechanical strength

-

Roll packaging for transportation and storage

Advantages Over Traditional Materials

| Feature | Color Metallized Film | Aluminum Foil | Plain Plastic Film |

|---|---|---|---|

| Weight | Lightweight | Heavy | Light |

| Barrier | High | Very High | Low |

| Color & Gloss | Customizable | Limited | Limited |

| Flexibility | High | Low | High |

| Cost | Moderate | High | Low |

| Printability | Excellent | Limited | Moderate |

Color Metallized Film balances aesthetics, barrier performance, and cost, making it suitable for modern packaging and decorative industries.

Market Trends and Sustainability

Increasing Demand for Flexible Packaging

-

Driven by snack, beverage, cosmetic, and pharmaceutical sectors.

-

E-commerce growth favors lightweight, durable, and visually appealing packaging.

Eco-Friendly Innovation

-

Uses minimal metal, reducing environmental impact.

-

PET, BOPP, and PE substrates are recyclable, supporting sustainable packaging initiatives.

Technological Advancements

-

Development of ultra-thin aluminum layers reduces metal use while maintaining barrier performance.

-

Advanced coating and lamination techniques improve durability, printability, and barrier properties.

-

Integration of smart packaging features like QR codes, RFID, or freshness indicators.

How to Choose the Right Color Metallized Film

-

Barrier Requirements: Choose appropriate metal thickness for oxygen/moisture resistance.

-

Film Thickness: 6–125 microns based on application; thicker films for industrial uses.

-

Surface Finish: Glossy, matte, metallic, or pearlescent.

-

Color Requirements: Choose coatings/dyes for brand consistency.

-

Lamination Compatibility: Confirm compatibility with PE, PET, BOPP, or paper.

-

Regulatory Compliance: Food-grade, cosmetic-grade, or industrial-grade certifications as required.

Frequently Asked Questions (FAQs)

Is Color Metallized Film recyclable?

Yes. PET, BOPP, and PE substrates are recyclable, though aluminum layer separation may require specialized processes.

Can Color Metallized Film be used for food packaging?

Yes. Complies with FDA, EU REACH, and ISO standards for safe food contact.

How long does it maintain barrier properties?

Typically 1–5 years depending on storage conditions, light exposure, and humidity.

Can it be laminated?

Yes. Often laminated with PE, PET, BOPP, or paper to improve barrier, mechanical properties, and printability.

Can it be printed and hot-stamped?

Yes. Corona-treated surface allows flexographic, gravure, digital printing, and hot stamping, enhancing decorative effects.

Conclusion

Color Metallized Film is a versatile material that combines metallic luster, vibrant colors, barrier performance, and flexibility. Widely used in food, cosmetics, medical, electronics, industrial, and decorative applications, it offers a cost-effective, lightweight, and visually appealing solution for modern packaging and decorative industries.

Tradsark provides customizable Color Metallized Film with a wide range of thicknesses, widths, roll lengths, aluminum layer thicknesses, and color coatings, helping businesses enhance product appearance, protect contents, reduce costs, and support sustainability goals.