Key Features of Black PE Film

Material Composition

Black PE Film is produced from high-density polyethylene (HDPE) or linear low-density polyethylene (LLDPE), depending on the application requirements. Carbon black and other additives are incorporated to provide the following:

-

UV Protection: Prevents degradation under long-term sunlight exposure.

-

Anti-Oxidation: Reduces material aging for prolonged lifespan.

-

Thermal Stability: Maintains structural integrity under high and low temperatures.

-

Flexibility & Strength: Resists tearing while allowing ease of installation over uneven soil surfaces.

Thickness & Mechanical Properties

Black PE Film comes in multiple thicknesses to suit different agricultural applications:

-

Thickness: 15μm, 16μm, 18μm, 20μm, 25μm, 30μm

-

Width: 1m, 1.2m, 1.5m, 2m, 2.3m, 2.5m

-

Length: 1200m, 2000m, 3000m

The mechanical properties of the film ensure durability, allowing it to withstand repeated tension, folding, and handling during installation. The combination of thickness and flexibility ensures optimal soil coverage while maintaining ease of use.

Optical and Thermal Properties

Black PE Film is designed to optimize the thermal and optical environment of crops:

-

Light Blocking: Prevents sunlight from reaching the soil, inhibiting weed growth.

-

Heat Retention: Traps soil heat to maintain stable root temperatures.

-

Moisture Control: Reduces soil evaporation, maintaining optimal soil moisture for crop growth.

These properties contribute to improved plant health, earlier fruiting, and higher yields.

Manufacturing Process

1. Extrusion and Film Formation

Black PE Film is produced through the extrusion process. PE resin and additives are melted and extruded through a die to form a uniform film. The thickness is carefully controlled to achieve the required mechanical properties and flexibility.

2. Cooling and Stretching

After extrusion, the film is cooled and optionally biaxially stretched to enhance strength, tear resistance, and dimensional stability.

3. Additive Integration

During production, carbon black, UV stabilizers, and antioxidants are integrated into the film matrix to improve weather resistance, color stability, and long-term durability.

4. Quality Control

Each roll undergoes rigorous inspection for thickness consistency, tensile strength, elongation, and UV resistance to ensure it meets industry standards.

Applications of Black PE Film

1. Strawberry Planting

Black PE Film is commonly used in strawberry farms to cover the soil. Its dark color absorbs sunlight, warms the soil, and suppresses weeds. Benefits include:

-

Improved strawberry fruit color and sweetness.

-

Reduced weed growth without chemical herbicides.

-

Maintained soil moisture for optimal growth.

2. Fruit Orchards

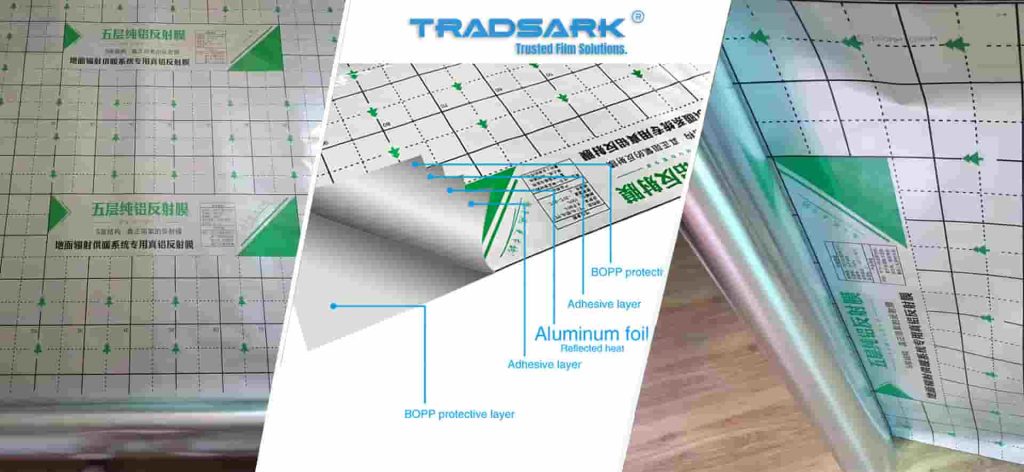

When used under fruit trees such as apples, pears, or peaches, black PE film can be combined with reflective aluminized films. The black film controls soil temperature while the reflective film enhances leaf canopy light exposure. This combination:

-

Increases leaf density.

-

Improves blossom rates and fruit sets.

-

Enhances overall fruit quality and marketable yield.

3. Vegetable Farming

In vegetable cultivation, black PE film is used to:

-

Improve soil warming and early planting.

-

Suppress weeds to reduce labor costs.

-

Enhance water retention for consistent growth.

4. Greenhouse and Horticultural Applications

Black PE Film is widely used in greenhouse settings to cover soil or beds, helping regulate temperature, prevent algae growth, and optimize plant health.

Advantages of Black PE Film

1. Weed Control

By blocking sunlight, the film prevents the germination and growth of weeds, reducing the need for herbicides and manual labor.

2. Soil Moisture Retention

The film helps maintain consistent soil moisture, reducing irrigation frequency and improving water-use efficiency.

3. Improved Crop Quality

The controlled microenvironment created by the black PE film promotes better root development, higher leaf density, more uniform flowering, and better fruit coloration.

4. Durability and Longevity

With UV stabilizers and antioxidants, Black PE Film can last for one or multiple growing seasons without significant degradation.

5. Cost-Effectiveness

Lightweight and easy to handle, the film reduces installation labor costs and transportation costs while improving crop yields, providing excellent return on investment.

6. Eco-Friendly

The film can be recycled at the end of its service life, and its use reduces the need for chemical weed killers, supporting sustainable agriculture practices.

Installation Guidelines

-

Preparation: Clean the soil surface, removing stones and debris.

-

Laying the Film: Place the film along crop rows, ensuring tight soil contact for effective thermal and moisture control.

-

Fixing: Anchor edges with soil, clips, or stakes to prevent wind displacement.

-

Maintenance: Monitor for tears or damage during the season and repair as needed.

-

Removal: At the end of the growing season, remove and recycle the film properly.

Customization Options

Black PE Film can be tailored to customer needs:

-

Thickness: From 15μm to 30μm or more.

-

Width & Length: Wide range to fit different planting layouts.

-

UV Resistance: Enhanced for prolonged exposure in high-sunlight regions.

-

Additives: Custom formulations for anti-fungal, anti-static, or biodegradable properties.

Market Trends and Insights

-

Increasing demand for sustainable agricultural practices drives the adoption of black PE film.

-

Integration with reflective and colored films for optimized crop growth is becoming more common.

-

Research in biodegradable PE films offers environmentally friendly alternatives.

-

Technological innovations are improving UV resistance, tensile strength, and film longevity.

Frequently Asked Questions (FAQs)

Q1: How long does Black PE Film last?

A: With proper installation, UV-resistant black PE film can last 1–3 growing seasons, depending on climate and usage.

Q2: Can Black PE Film be recycled?

A: Yes, it can be collected and recycled into new PE films, supporting sustainable practices.

Q3: Is it safe for food crops?

A: Yes, the materials used are non-toxic and approved for agricultural use.

Q4: Can it be used together with reflective films?

A: Absolutely. Using black PE film with reflective films optimizes both soil management and canopy light reflection.

Conclusion

Black PE Film is a highly versatile, durable, and effective solution for modern agriculture. Its properties make it suitable for a wide range of crops, from strawberries to fruit orchards and vegetables. By combining soil moisture retention, weed control, thermal regulation, and durability, it helps farmers improve yield, quality, and profitability. With customizable specifications and environmentally friendly options, Black PE Film is a smart choice for professional growers seeking high-performance agricultural solutions.