Aluminized Polyester Film Technical Date Sheet

| Property | Unit | Typical values | Test methods | |

| Thickness | μm | 10-75 | GB/T16958-2008 | |

| Tensile strength | MD | MPa | 200 | GB/T16958-2008 |

| TD | 200 | |||

| Elastic Modulus | MD | MPa | 3600 | GB/T16958-2008 |

| TD | 3600 | |||

| Elongation at break | MD | % | 100 | GB/T16958-2008 |

| TD | 100 | |||

| Thermal Shrinkage | MD | % | 2 | GB/T16958-2008 (150°C. 30min) |

| TD | 0.2 | |||

| Friction coefficient | Static | 0.6 | GB/T10006-1998 | |

| Dynamic | 0.55 | |||

| Haze | % | 3.5 | GB/T2410 | |

| Glossiness | % | 120 | GB/T8807 | |

| Wetting tension | mN/M | 54 | GB/T14216 | |

| Note: The aboves values are typical test data of physical properties of the company’s products,which are only for reference.We can produce according to customers’requirements. | ||||

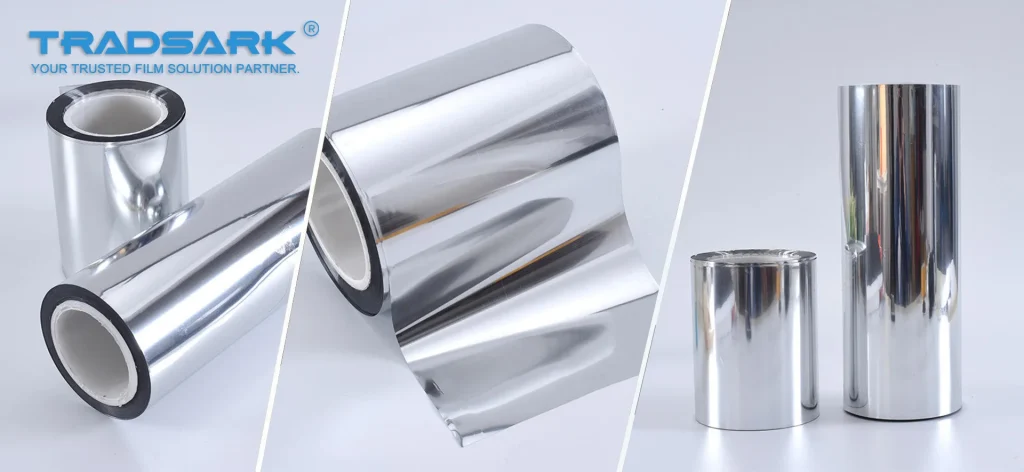

Aluminized Polyester Film Specification

| Type | Aluminized Polyester Film | Application | Packaging |

| Thickness(μm) | 8~60 | Certificate | ISO9001 / CE / UL |

| Width(mm) | 300~2000 | Package | Pallet |

| Diameter(mm) | 240~400 | Sample | Free |

| Paper Core(inch) | 3″/6″ | Payment | T/T, LC, PayPal, Western Union |

| Material | Polyethylene Terephthalate/AL | MOQ | 1000KG |

| Corona Treatment | One side | Port | Qingdao Port |

| Processing Type | Aluminum Coating | Place of Origin | China |

Key Features & Advantages of Aluminized Polyester Film

-

Superior Barrier Properties

-

Excellent resistance to oxygen, moisture, and light.

-

Extends shelf life and maintains product freshness.

-

Protects sensitive items such as snacks, medicines, and electronics.

-

-

Outstanding Mechanical Strength

-

Excellent puncture resistance, tear resistance, and tensile strength.

-

Supports high-speed automated packaging, sealing, and laminating.

-

-

Good Heat Resistance & Insulation

-

Stable under high temperatures.

-

Performs well in heat-sealing applications and insulation layers.

-

-

UV & Light Blocking Properties

-

Protects products from harmful UV rays.

-

Suitable for light-sensitive goods like pharmaceuticals and food.

-

-

Metallic Luster & Decorative Appeal

-

Eye-catching glossy surface for premium product packaging.

-

Ideal for tobacco, alcohol, luxury goods, and gift wrapping.

-

-

Processing Flexibility

-

Compatible with lamination, printing, coating, slitting, and adhesive processes.

-

Suitable for custom branding, labeling, and flexible packaging solutions.

-

-

Cost-Effective Alternative to Aluminum Foil

-

Lighter and more flexible.

-

Lower cost while maintaining comparable barrier performance.

-

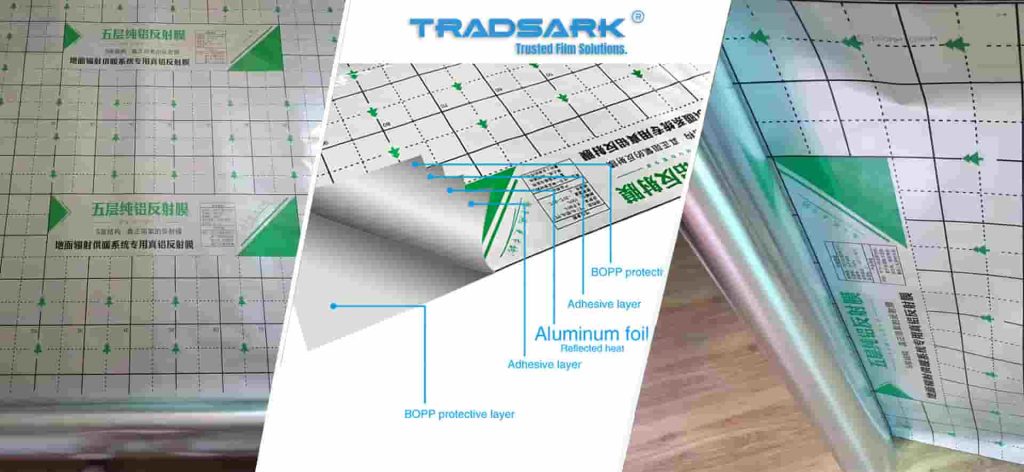

Production Process

Tradsark uses advanced vacuum metallization technology to produce aluminized polyester films:

-

PET Film Base – High-quality PET film is prepared with excellent mechanical and thermal properties.

-

Vacuum Aluminum Deposition – Pure aluminum is evaporated in a high-vacuum chamber.

-

Condensation on PET Film – Aluminum atoms are deposited evenly onto the PET film surface.

-

Finishing & Slitting – The film is cooled, inspected, and slit into required widths and thicknesses.

-

Quality Testing – Each batch is tested for barrier properties, coating adhesion, and strength.

This process ensures a uniform aluminum coating with excellent reflectivity, barrier performance, and durability.

Applications of Aluminized Polyester Film

1. Food Packaging

-

Snack foods, biscuits, puffs, and confectionery.

-

Powdered products such as milk powder, coffee, and tea.

-

Preserves freshness and aroma, prevents contamination.

2. Pharmaceutical Packaging

-

Ideal for light- and moisture-sensitive medicines.

-

Protects capsules, tablets, and powders from environmental degradation.

3. Electronics Industry

-

Electromagnetic shielding materials.

-

Protection of sensitive electronic components.

-

Used in cables, insulation layers, and anti-interference coatings.

4. Decorative Materials

-

Gift wraps, luxury product packaging, and labels.

-

Metallic luster creates a premium visual effect.

-

Used in gold/silver card paper, stickers, and specialty printing.

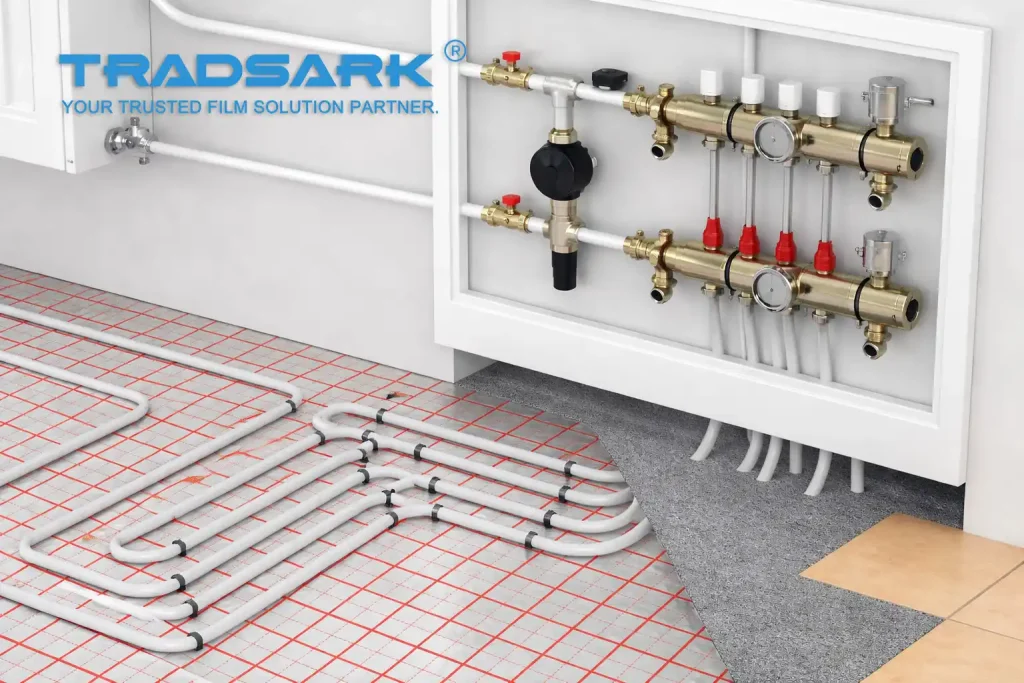

5. Construction & Insulation

-

Heat insulation materials for buildings.

-

Reflective layers in air conditioning and floor heating systems.

-

Energy-saving reflective films for agriculture.

6. Agriculture

-

Agricultural reflective films for greenhouses.

-

Improves plant growth by enhancing light utilization.

Comparison with Other Materials

| Property | Aluminized PET Film | Aluminum Foil | Regular PET Film |

|---|---|---|---|

| Barrier Properties | Excellent | Excellent | Moderate |

| Flexibility | High | Low | High |

| Cost | Lower | Higher | Moderate |

| Weight | Lightweight | Heavy | Lightweight |

| Appearance | Glossy Metallic | Metallic | Transparent |

| Applications | Food, Pharma, Decoration, Insulation | Food, Pharma | Packaging, Lamination |

👉 Conclusion: Aluminized PET film offers a balanced solution with excellent performance at lower cost compared to aluminum foil.

Tradsark Advantages as a Manufacturer & Supplier

-

Advanced Production Facilities – Equipped with modern vacuum metallization equipment.

-

Strict Quality Control – ISO9001, ISO14001, ISO45001 certified.

-

Food-Grade Certifications – CE food-grade certified, safe for direct food contact.

-

Custom Solutions – Available in different thicknesses (8μm–50μm), widths, and rolls.

-

Global Supply Capability – Exporting to South America, Central Asia, Russia, Europe, and worldwide.

-

Competitive Pricing – Direct factory supply ensures affordability without compromising quality.

Technical Specifications

-

Material: PET (Polyethylene Terephthalate)

-

Coating: Vacuum-deposited aluminum layer

-

Thickness: 8μm – 50μm

-

Width: Up to 2200mm (customizable)

-

Roll Diameter: As per customer requirement

-

Surface Treatment: Corona treatment, printable

-

Colors: Silver metallic (custom metallization available)

-

Properties:

-

Oxygen Transmission Rate (OTR): < 2 cc/m²/day

-

Water Vapor Transmission Rate (WVTR): < 2 g/m²/day

-

Reflectivity: > 90%

-

Tensile Strength: Excellent

-

Quality & Certifications

Tradsark’s aluminized polyester films comply with international standards:

-

ISO9001 – Quality Management System

-

ISO14001 – Environmental Management System

-

ISO45001 – Occupational Health & Safety

-

CE Certification – Food-grade safety standard

These certifications ensure consistent quality, safe production, and eco-friendly processes.

Frequently Asked Questions (FAQ)

Q1: Is aluminized PET film food-safe?

Yes. Tradsark produces food-grade aluminized films certified under CE and ISO standards.

Q2: Can it replace aluminum foil in packaging?

In many cases, yes. It offers comparable barrier performance with lower weight and cost.

Q3: What thicknesses are available?

From 8μm to 50μm, depending on application needs.

Q4: Can the film be printed or laminated?

Yes. It supports lamination, printing, coating, and adhesive processing.

Q5: Do you provide custom sizes?

Absolutely. Widths, rolls, and thickness can all be customized.

Why Choose Tradsark?

-

Reliable China manufacturer & supplier of polyester films.

-

Full product range: CPP, BOPP, BOPET, PET, Aluminized Films.

-

Trusted by customers in packaging, food, electronics, and agriculture.

-

One-stop flexible packaging solution provider.

-

Customer-first approach with fast delivery and technical support.

Contact Us

📞 Tradsark New Materials (Weifang) Co., Ltd.

🌐 Website: https://www.tradsark.net

📧 Email: tradsark@gmail.com | info@tradsark.net

📱 WhatsApp: +86 190 0646 0458

☎ Phone: +86 190 0646 0458