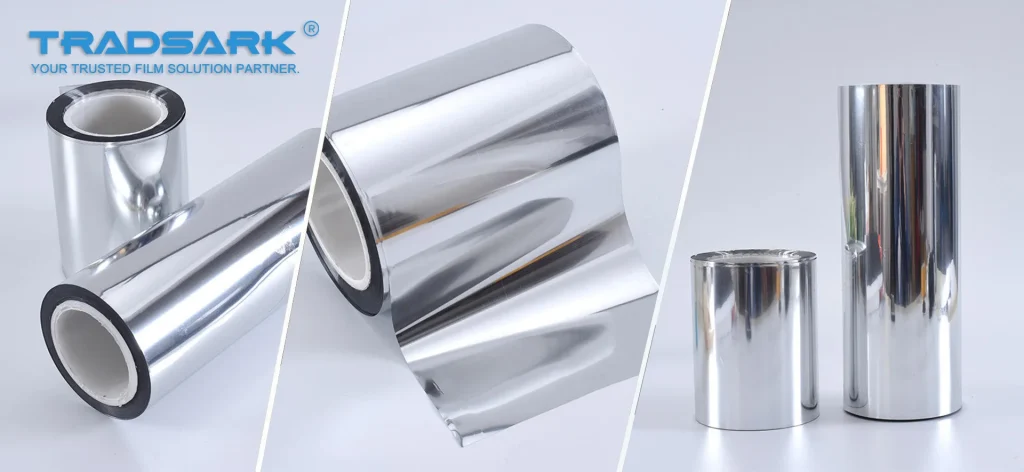

Key Features and Benefits of Aluminized PET Film

-

Excellent Gas and Light Barrier Properties

The aluminum layer applied to PET film creates a strong barrier against gases, making aluminized PET an ideal choice for packaging products that need to be protected from oxygen, moisture, and light. This helps preserve the freshness of food products, extend the shelf life of sensitive materials, and maintain the quality of pharmaceuticals or electronics. -

Superior Moisture Barrier Performance

Aluminized PET film offers exceptional moisture barrier properties, which are essential for packaging applications where moisture resistance is critical. This feature prevents moisture from compromising the integrity of the packaged product, such as food, medical supplies, or other moisture-sensitive items. -

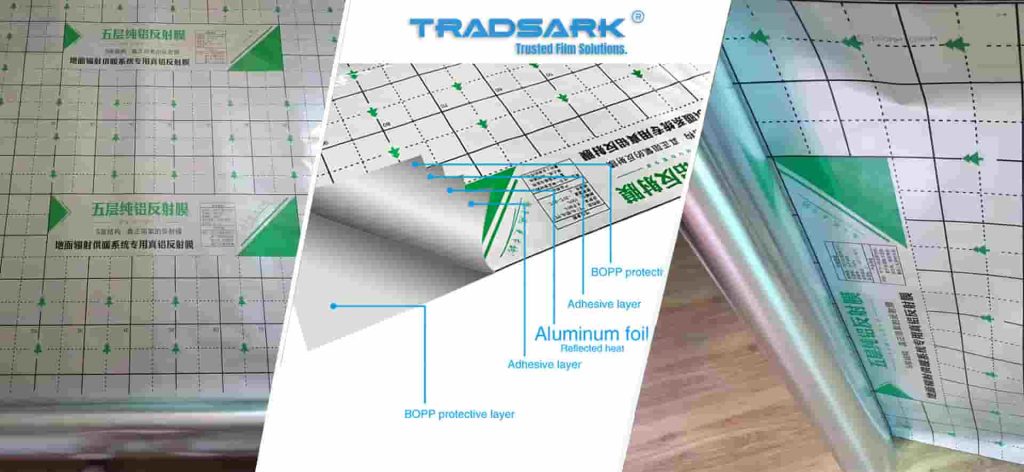

Outstanding Heat Resistance

Aluminized PET film is known for its excellent heat resistance. It can withstand high temperatures without degrading, making it suitable for applications that require exposure to elevated heat conditions. Whether it’s for thermal insulation or heat-sensitive packaging, aluminized PET can handle a wide range of temperature fluctuations. -

Exceptional Puncture Resistance

The PET base combined with the aluminum layer gives the film excellent puncture resistance. This makes aluminized PET ideal for packaging applications where the material must withstand rough handling, transport, or physical impacts. Its strong mechanical properties ensure durability during shipping and storage. -

Good Processing and Decorative Properties

Aluminized PET film is easy to process and can be tailored for different packaging and decorative applications. It offers high printability, allowing for vibrant graphics, logos, and brand messaging to be easily applied. Its reflective metallic surface also adds a premium visual appeal, making it an ideal material for luxury packaging and decorative uses. -

UV Blocking

The aluminum coating not only provides a shiny metallic finish but also blocks harmful UV rays. This UV-blocking feature helps protect sensitive products from sun exposure, preventing degradation or color fading. It’s especially useful in food packaging, cosmetics, and electronics, where UV protection is essential to preserve product quality. -

Metallic Luster

Aluminized PET film has a brilliant metallic luster, which adds a sophisticated and high-end appearance to products. This attractive finish enhances the appeal of the packaging, making it ideal for premium products, luxury goods, and high-visibility applications where aesthetics are important.

Aluminized PET Film Technical Date Sheet

| Property | Unit | Typical values | Test methods | |

| Thickness | μm | 10-75 | GB/T16958-2008 | |

| Tensile strength | MD | MPa | 200 | GB/T16958-2008 |

| TD | 200 | |||

| Elastic Modulus | MD | MPa | 3600 | GB/T16958-2008 |

| TD | 3600 | |||

| Elongation at break | MD | % | 100 | GB/T16958-2008 |

| TD | 100 | |||

| Thermal Shrinkage | MD | % | 2 | GB/T16958-2008 (150°C. 30min) |

| TD | 0.2 | |||

| Friction coefficient | Static | 0.6 | GB/T10006-1998 | |

| Dynamic | 0.55 | |||

| Haze | % | 3.5 | GB/T2410 | |

| Glossiness | % | 120 | GB/T8807 | |

| Wetting tension | mN/M | 54 | GB/T14216 | |

| Note: The aboves values are typical test data of physical properties of the company’s products,which are only for reference.We can produce according to customers’requirements. | ||||

Specification

| Type | Metalized PET Film | Application | Packaging |

| Thickness(μm) | 8~60 | Certificate | ISO9001 / CE / UL |

| Width(mm) | 300~2000 | Package | Pallet |

| Diameter(mm) | 240~400 | Sample | Free |

| Paper Core(inch) | 3″/6″ | Payment | T/T, LC, PayPal, Western Union |

| Material | Polyethylene Terephthalate/AL | MOQ | 1000KG |

| Corona Treatment | One side | Port | Qingdao Port |

| Processing Type | Aluminum Coating | Place of Origin | China |

Applications of Aluminized PET Film

Aluminized PET film is widely used in a variety of industries due to its unique combination of barrier properties, durability, and aesthetic appeal. Some common applications include:

-

Food Packaging: Widely used for packaging snacks, confectionery, and beverages, aluminized PET provides superior barrier properties to protect against moisture, light, and oxygen, preserving the taste and freshness of food products.

-

Pharmaceutical Packaging: Aluminized PET is commonly used in packaging for pharmaceuticals and medical products that require protection from moisture, oxygen, and UV rays.

-

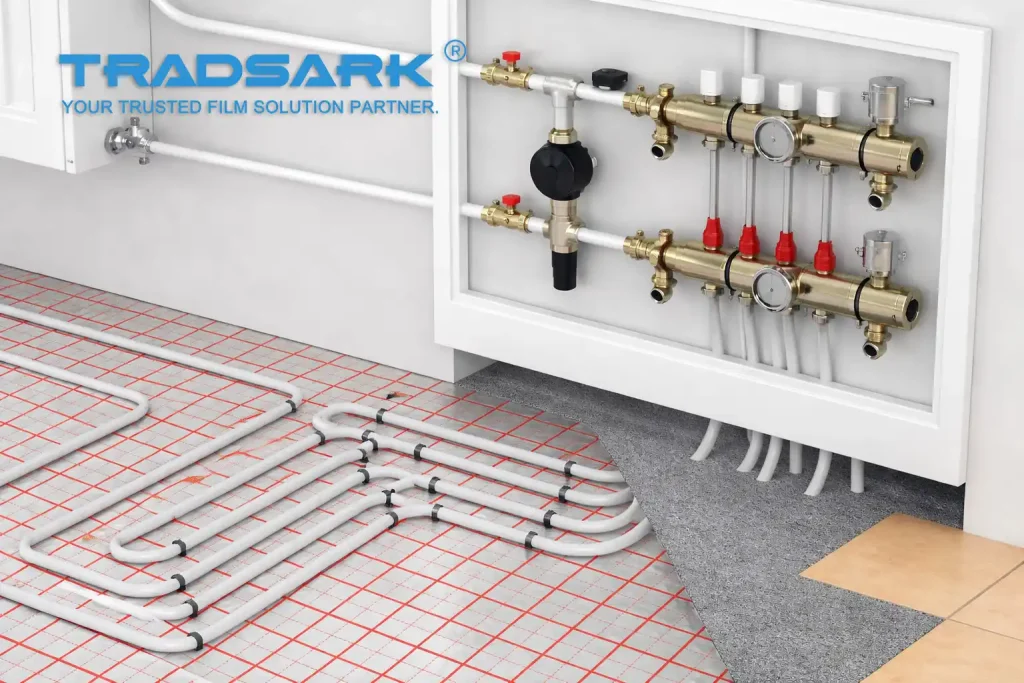

Thermal Insulation: Due to its excellent heat resistance, aluminized PET is used in insulation applications, including thermal blankets, automotive insulation, and building materials.

-

Cosmetic Packaging: The shiny metallic finish of aluminized PET makes it a popular choice for high-end cosmetics and personal care products. It adds luxury appeal and enhances the product’s image on the shelf.

-

Decorative Applications: Aluminized PET is used in various decorative applications, such as in gift wraps, banners, and point-of-sale displays, thanks to its eye-catching metallic surface.

Advantages of Aluminized PET Film

-

Superior Barrier Properties: Excellent protection against moisture, oxygen, and light, preserving the quality of sensitive products.

-

Durability: The film is highly resistant to punctures, tears, and physical damage, making it ideal for transportation and long-term storage.

-

Heat and UV Resistance: Can withstand high temperatures and block harmful UV rays, making it suitable for a range of applications.

-

Premium Aesthetic Appeal: The metallic finish enhances the visual appeal of packaging, making it ideal for high-end products.

-

Good Processability: The film is easy to process and print on, enabling detailed graphics and brand messages to be applied effectively.

Conclusion

Aluminized PET Film is a versatile and high-performance material that provides outstanding barrier properties, durability, and an attractive metallic finish. It is ideal for a wide range of packaging, insulation, and decorative applications. With its superior performance and aesthetic appeal, aluminized PET is the material of choice for industries that require both protection and premium presentation.

For more information or to inquire about aluminized PET film for your next project, contact Tradsark New Materials Co., Ltd. today. We offer high-quality aluminized PET films tailored to meet the specific needs of your industry.