Chapter 1: Introduction & Product Overview: Maximizing Light Efficiency in Modern Agriculture

What is PE & PET Silver Mylar Reflective Film?

PE & PET Silver Mylar Reflective Film is a precision-engineered optical surfacing material designed for high-performance agriculture. This advanced film is manufactured using a sophisticated Vacuum Metallizing (PVD) process, where a layer of 99.9% pure aluminum is vapor-deposited onto a high-strength polymer base of either PET (Polyester) or PE (Polyethylene).

- PET (BOPET) Base Version: As the tradsark flagship solution, this version utilizes Biaxially-oriented Polyethylene Terephthalate. It is characterized by extreme mechanical strength and high-temperature resistance (up to 120°C). It is the industry standard for high-intensity HID/LED grow rooms and vertical farming systems.

- PE (Polyethylene) Base Version: This version focuses on flexibility and environmental adaptability. With superior moisture resistance and cost-efficiency, it is the ideal choice for large-scale outdoor orchards (such as apples and grapes) to be used as a Reflective Ground Cover.

Core Functions: Industrial-Grade Optical Performance

For B2B buyers and commercial growers, tradsark products deliver critical technical advantages:

- Ultra-High Total Reflectivity (≥ 95-98%): Our Reflective Mylar Film eliminates shadow zones. By utilizing specular reflection, it redirects wasted light back to the lower canopy and under-foliage, significantly boosting PAR (Photosynthetically Active Radiation).

- Thermal Management & Infrared Blocking: The aluminized layer reflects approximately 90% of infrared heat. In outdoor settings, it prevents soil overheating to protect root systems; in greenhouses, it helps lock in thermal energy during winter, reducing heating overheads.

- Advanced Anti-Oxidation Coating: Unlike generic materials, our Aluminized Mylar features a nano-passivation layer. This ensures the silver surface remains intact and highly reflective even when exposed to high humidity, nutrient spraying, and acidic rain (preventing de-alumination).

Why Commercial Growers and Greenhouse Farms Choose This Solution?

In the pursuit of maximum ROI (Return on Investment), Mylar polyester film has become a vital tool for reducing operational costs:

- Increased Marketable Yield: For outdoor fruit trees like apples and grapes, this Plant Reflective Film solves the problem of uneven coloration. Increased light penetration promotes full-color fruit development and allows for harvesting 5-7 days earlier, directly boosting market value.

- Reduced Supplemental Lighting Costs: Greenhouse operators can achieve a 20%-30% increase in light intensity without adding extra fixtures or increasing electricity bills, simply by installing Reflective Mylar Film Rolls on walls or floors.

- Long-Term Durability & Reduced Replacement Frequency: tradsark industrial-grade PET film offers exceptional tear resistance and UV stability. It is built to withstand outdoor wind loads and frequent maintenance, ensuring your investment covers multiple growing seasons.

Chapter 2: Key Features & Benefits — Engineering the Future of Agricultural Reflectivity

In professional cultivation, reflective film is not merely a cover; it is a critical optical regulation system. tradsark’s PE & PET Silver Mylar films are engineered not only for peak reflectivity but also for extreme environmental stability in industrial-scale operations.

1. Advanced Optical and Physical Performance

- Total Spectral Reflectivity (≥ 98%)Our reflective mylar for plants is created through high-purity aluminum vapor deposition in a controlled vacuum environment. Unlike generic alternatives, it reflects the full spectrum of Photosynthetically Active Radiation (PAR), from blue to deep red.

- The Advantage: This ensures maximum light absorption for crops without increasing electricity consumption, making it an essential tool for sustainable high-yield farming.

- High-Tensile Tear ResistanceUtilizing biaxially-oriented polyester (BOPET) technology, our Mylar polyester film provides exceptional mechanical strength. Even at 15μm thickness, its tensile strength outperforms significantly thicker standard plastic films.

- The Advantage: It resists wind-tearing in outdoor orchards and withstands the mechanical stress of automated installation, drastically reducing maintenance and replacement costs.

- Infrared Barrier & Micro-Climate ControlBeyond visible light, the aluminized layer acts as a high-efficiency infrared mirror.

- The Advantage: In outdoor orchards, it prevents soil moisture from evaporating too quickly by reflecting radiant heat; in greenhouses, it traps thermal energy during cold nights, reducing heating overheads by up to 15%.

2. Comprehensive Technical Specifications Data

As YOUR TRUSTED FILM SOLUTION PARTNER, tradsark provides standardized industrial parameters to ensure compatibility with automated laying equipment and diverse climatic conditions.

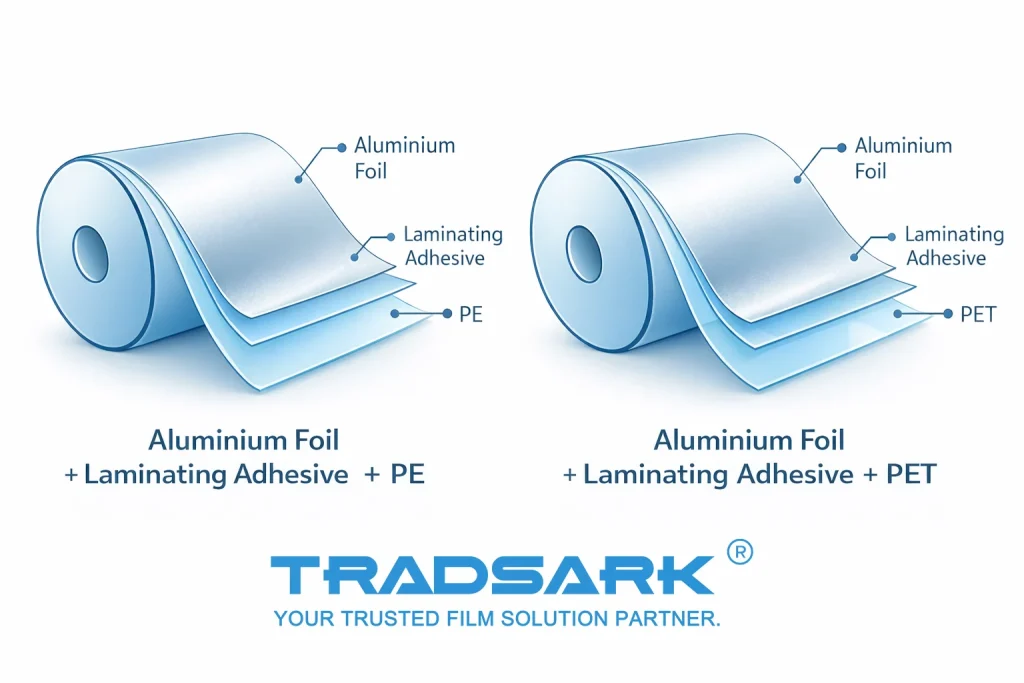

A. Material Structural Composition

| Product Series | Layer Structure | Core Engineering Property |

| Aluminized PET | Protective Coating + Pure Alum + Adhesive + PET Base | Extreme Stability: Heat resistant up to 120°C; zero shrinkage; superior mirror finish; ideal for permanent greenhouse wall linings. |

| Aluminized PE | Protective Coating + Pure Alum + Adhesive + PE Base | Maximum Flexibility: High puncture resistance; acid/alkali resistant; conforms perfectly to uneven orchard terrain. |

B. Dimensions & Available Formats

| Technical Parameter | Specification Range | Application Insight |

| Thickness | 15μm – 30μm (Customizable) | 15-18μm is optimized for seasonal orchard mulching; 25μm+ is designed for long-term greenhouse durability. |

| Standard Width | 1m, 1.2m, 1.5m, 2m, 2.5m (Max) | Ultra-wide 2.5m format reduces seams in large greenhouses, accelerating installation time. |

| Roll Length | 1200m, 2000m, 3000m | Extended lengths minimize downtime during automated laying processes in large-scale farms. |

| Corrosion Resistance | Nano-Passivation Coating | Ensures the aluminum layer remains intact for 12-24 months despite exposure to pesticides and nutrient sprays. |

3. Productivity Enhancement: Real-World Application Growth

Our agricultural reflective film serves as a productivity multiplier rather than just a protective layer:

“This professional-grade reflective Mylar film is available in precision-cut rolls and sheets, making it indispensable for both ground cover and greenhouse lining. By redistributing PAR to the lower quadrants of the plant, it significantly shortens harvest cycles. For instance, in apple and grape orchards, using our reflective mylar sheet as ground cover ensures 100% skin coloration and accelerates sugar accumulation, directly increasing the market grade and value per ton of produce.”

Chapter 3: Key Features & Versatile Applications — Engineering the Future of Agricultural Reflectivity

In modern high-yield cultivation, PE & PET Silver Mylar Reflective Film is more than just a covering material; it is a precision-engineered optical regulation system. By merging industrial-grade physical properties with multi-scenario adaptability, tradsark provides a definitive solution to maximize light energy utilization for global growers.

1. Core Technical Features & Specifications

Our products are specifically reinforced for the rigors of commercial farming, offering irreplaceable physical advantages:

- Full-Spectrum High Reflectivity (≥ 98%): Utilizing advanced vacuum aluminum vapor deposition, our film ensures that the entire PAR (Photosynthetically Active Radiation) spectrum—from blue to deep red—is reflected with maximum efficiency.

- Industrial-Grade Tear Resistance: Built with Biaxially-oriented Polyethylene Terephthalate (BOPET) technology, our Mylar polyester film delivers exceptional tensile strength, capable of withstanding heavy wind loads in outdoor orchards and the mechanical stress of automated laying equipment.

- Weatherproof & Anti-Corrosive: The surface features a nano-scale anti-oxidation coating. This ensures the aluminum layer remains intact for 12–24 months without flaking or de-alumination, even when exposed to high humidity, pesticides, or nutrient sprays.

2. Versatile Applications: From Laboratories to Vast Orchards

Silver Plant Reflective Film for Garden and Greenhouse applications improves light distribution, making it a superior productivity multiplier across various sectors:

A. Commercial Greenhouses & Indoor Vertical Farms

In controlled environments, every lumen lost is a waste of capital.

- Linings & Supplemental Lighting: Installing Reflective Mylar Film Rolls on walls or ceilings eliminates shadow zones and increases light intensity for lower-tier plants by 20%–30%.

- Thermal Management: The film reflects up to 90% of radiant heat, helping balance the indoor micro-climate and reducing heating costs during winter months.

B. Large-Scale Agricultural Orchards

For high-value crops like apples, grapes, and citrus, this product is the key to increasing marketable yields.

- Reflective Ground Cover: When used as an agricultural reflective film laid between rows, it redirects sunlight to the underside of the fruit. This eliminates uneven coloring, accelerates sugar accumulation, and allows crops to reach the market 5–7 days earlier.

- Physical Pest Control: The intense reflection interferes with the visual orientation of pests like aphids and thrips, reducing reliance on chemical pesticides.

C. Home Gardening & DIY Projects

- Flexible Adaptability: For smaller growers, we provide easy-to-cut reflective mylar sheets. Whether for a compact grow box or balcony supplement, it is easy to install and significantly increases gardening success rates.

- Efficient Coverage: As a dedicated reflective mylar for plants, it helps hobbyists maintain healthy greenery even in low-light indoor environments.

Chapter 3: Installation Guide & Best Practices — Maximizing Your Reflective Efficiency

The correct installation of PE & PET Silver Mylar Reflective Film is a decisive factor in achieving the highest yield increase. Based on tradsark’s extensive field experience, we have categorized the installation methods into three core scenarios with professional maintenance tips.

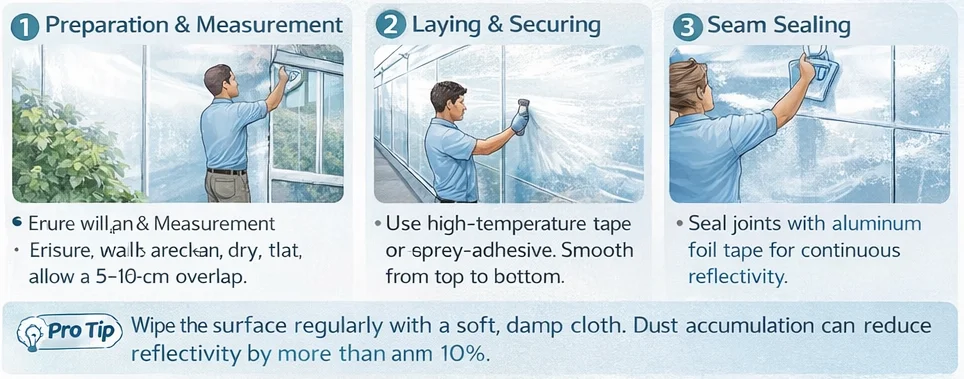

Scenario 1: Commercial Greenhouses & Grow Rooms (Wall & Lining Installation)

In controlled indoor environments, the goal is to create a “Light Cycle” where no lumen is wasted.

- Preparation & Measurement: Clean the wall surfaces to ensure they are dry and flat. When measuring height, we recommend allowing a 5-10 cm overlap at the seams.

- Laying & Securing: Use professional high-temperature resistant tape or spray adhesive to secure the Reflective Mylar Film Rolls. Always smooth the film from top to bottom to prevent large wrinkles, which can cause “Hot Spots” that might damage delicate plant tissues.

- Seam Sealing: Use aluminum foil tape to seal the joints. This ensures continuous reflectivity and acts as a moisture barrier to protect the underlying structure.

- Pro Tip: Regularly wipe the surface with a soft, damp cloth. Dust accumulation on reflective mylar for plants can reduce reflectivity by more than 10%.

Scenario 2: Outdoor Orchards (Reflective Ground Cover for Apples, Grapes, etc.)

In open-field environments, wind resistance and tensile strength are the primary considerations.

- Field Preparation: Before laying the agricultural reflective film, clear weeds and sharp stones from the rows to prevent accidental punctures.

- Automated or Manual Laying: Fix the large-diameter reflective ground cover onto a mulching machine and unfold it steadily along the rows.

- Anchoring: Secure the film with U-shaped sod staples every 1-2 meters or weigh down the edges with a small amount of fine soil. tradsark recommends avoiding excessive soil coverage to maintain the maximum reflective surface area.

- Pro Tip: For apple orchards, install the film 15-20 days before harvest. Avoid laying during the peak heat of the day to prevent excessive thermal expansion and contraction from affecting the film’s flatness.

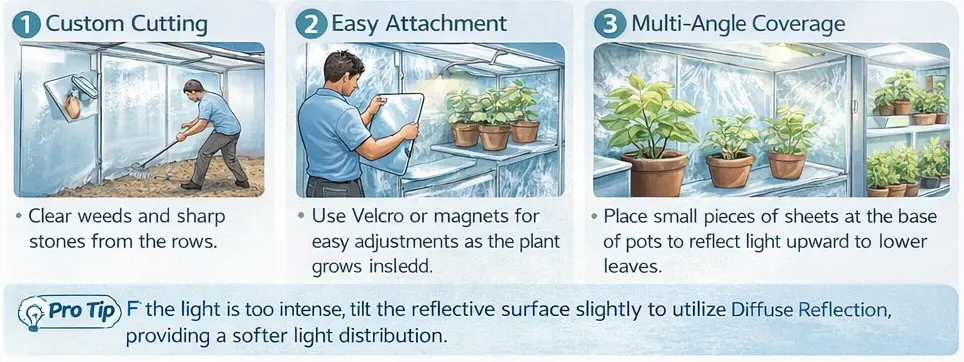

Scenario 3: Home Gardening & DIY Seedling (Flexible Sheet Covering)

For small-scale spaces, flexibility is the core focus.

- Custom Cutting: Cut the reflective mylar sheets into the desired shapes based on the dimensions of your grow box or shelving.

- Easy Attachment: Use Velcro or magnets for attachment, allowing for easy adjustments as the plant grows in height.

- Multi-Angle Coverage: Don’t just cover the back wall; place small pieces of reflective sheets at the base of pots to provide upward reflection to the lower leaves.

- Pro Tip: If the light is too intense, tilt the reflective surface slightly to utilize Diffuse Reflection, providing a softer light distribution.

Chapter 4: Why Choose Our PE & PET Silver Mylar Reflective Film?

1. Uncompromising Quality Control (QC)

At tradsark, we understand that in a multi-million dollar greenhouse, a film failure means a failed harvest.

- Premium Sourcing: We use only 99.9% pure aluminum and virgin PET/PE resins. No recycled materials. This guarantees superior tensile strength and optical purity.

- End-to-End Testing: Every Reflective Mylar Film Roll undergoes strict reflectivity consistency checks, adhesion tests (ASTM standards), and simulated UV aging before leaving our facility.

- Precision Thickness: What you order is exactly what you get. We never compromise on gauge thickness.

2. Certified Excellence (CE & ISO Compliance)

To facilitate seamless entry into global markets, tradsark products adhere to the highest international standards.

- ISO 9001:2015: Our production environment is managed under a world-class Quality Management System, ensuring batch-to-batch reliability.

- CE & RoHS Compliance: Our agricultural reflective film is non-toxic and eco-friendly, meeting the stringent safety requirements of modern sustainable horticulture.

3. Professional OEM / ODM Capabilities

Every crop has a different “light recipe.” tradsark provides customized engineering for your specific environment.

- Custom Specifications: Whether you need a specific thickness (12μm to 100μm+), ultra-wide formats (up to 2.5m), or custom roll lengths, we have the manufacturing flexibility to deliver.

- Functional Additives: We can enhance your film with extra UV stabilizers for extreme sun exposure or anti-fog coatings for humid greenhouse interiors.

4. Bulk Distribution & Global Logistics Expertise

As an experienced exporter, tradsark minimizes the friction of international trade.

- Competitive Scalability: Our manufacturing scale allows us to offer Tier-1 wholesale pricing to distributors and large-scale farm operators.

- Global Shipping Network: From the ports of Ningbo/Shanghai to your doorstep in North America, Europe, or the Middle East, we handle the complexity of global freight (Sea, Air, or Rail).

- Industrial Packaging: We use heavy-duty, moisture-proof packaging with reinforced pallets to ensure your reflective mylar sheets arrive in pristine condition after transoceanic transit.

Chapter 5: Start Your High-Efficiency Growing Journey Today!

Ready to optimize your agricultural project? Our team is standing by to provide you with technical specifications and competitive wholesale pricing.

- Wholesale & Custom Inquiries: Reach out today for a personalized quote.

- WhatsApp: +86 190 0646 0458

- Email: tradsark@gmail.com

- Slogan: YOUR TRUSTED FILM SOLUTION PARTNER