Engineering guidance for barrier packaging laminates, converting stability, and procurement clarity

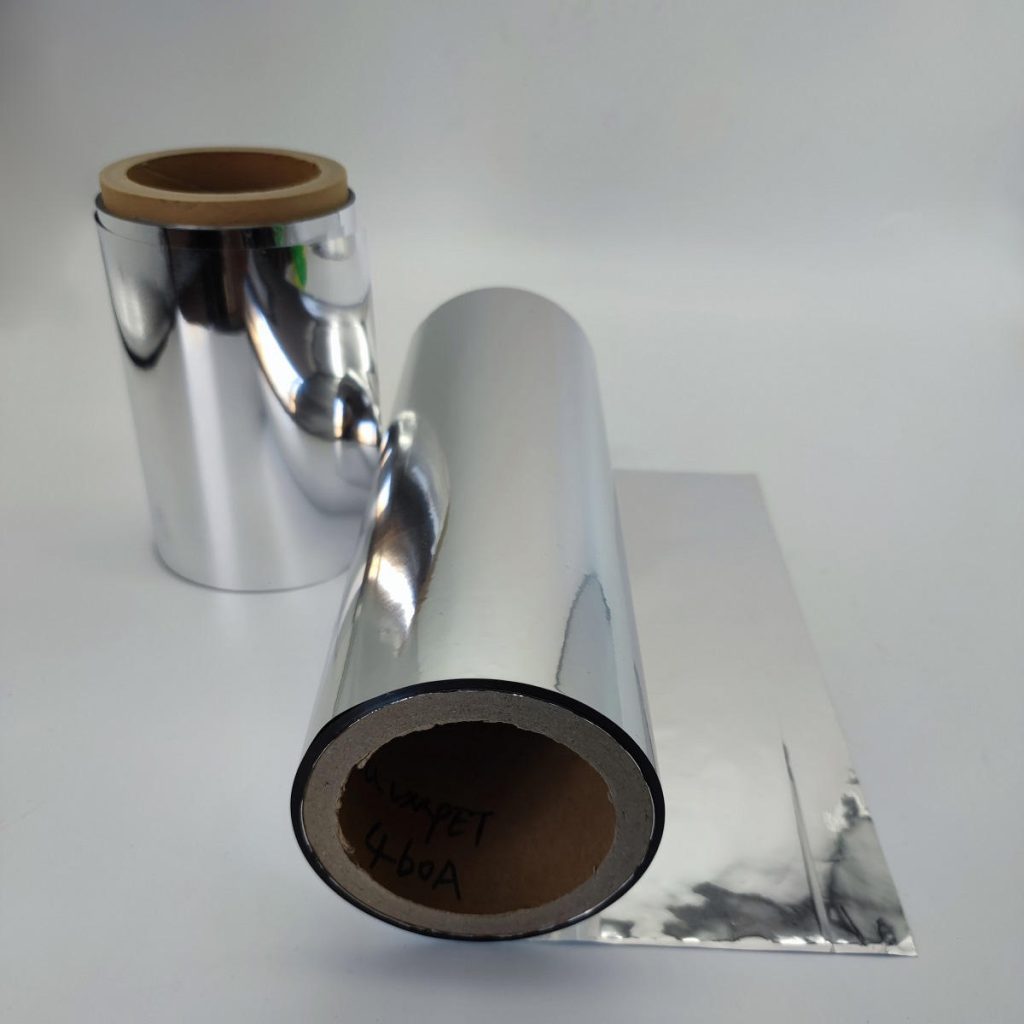

Metallized BOPP film is a biaxially oriented polypropylene (BOPP) substrate coated with an ultra-thin metal layer—most commonly aluminum—applied through vacuum metallization. In practical packaging engineering, this material is selected when a project requires a cost-efficient barrier upgrade and a high-gloss metallic appearance while still maintaining the web-handling advantages of oriented polypropylene. It is frequently used as an outer layer in laminated structures for snack packaging, dry goods, personal care items, electronics moisture protection, and selected medical or industrial packaging formats where light and moisture sensitivity must be managed.

Unlike a ”decorative silver film” description, an engineering definition focuses on how metallized BOPP works as a system component:

- The BOPP base film provides tensile strength, stiffness balance, and dimensional stability for high-speed printing/lamination.

- The metal layer improves barrier performance by reducing gas and moisture diffusion pathways, and it increases reflectivity and shelf impact.

- The surface treatment configuration (metallized side vs. treated side vs. heat-seal side) determines whether the film runs reliably in printing and whether it bonds consistently during lamination.

- The roll geometry and winding quality directly affect converting stability: tension behavior, telescoping risk, and defect visibility.

This solution guide is written for international buyers, packaging engineers, and converters who need not only ”features,” but also selection logic, specification language, and verification methods that reduce commercial disputes and improve on-line performance.

Tradsark can position metallized BOPP as a converting-ready barrier component supported by clear side mapping, test references, and consistent roll quality controls.

1) What Metallized BOPP Film Is

1.1 BOPP orientation and why it matters

BOPP is produced by stretching polypropylene in both the machine direction (MD) and transverse direction (TD). This biaxial orientation improves:

- Tensile properties and tear resistance balance

- Dimensional stability at converting speeds

- Film clarity (for non-metallized grades) and smoothness for metallization

- Uniform thickness control (critical for stable tension behavior)

In metallized BOPP, the base film quality has an outsized impact because the aluminum layer is extremely thin: any base surface defects, contamination, or roughness variability can translate into non-uniform metallization, pinholes, or reflectivity differences.

1.2 Vacuum metallization: what the metal layer really does

The metal layer is deposited in a vacuum chamber and is thin enough that the film remains flexible and lightweight. The barrier benefit comes from reducing permeation pathways and increasing the tortuosity for oxygen and moisture movement across the film. In practice, barrier performance depends on:

- Metal layer continuity (uniform coverage, minimal pinholes)

- Adhesion between metal layer and polymer surface

- Resistance to abrasion (metal layer damage can degrade appearance and barrier)

- Downstream lamination and sealing integrity (final package barrier is a system result)

1.3 ”Two-interface material”: the most common real-world mistake

Metallized BOPP should always be treated as a film with two functional sides, and the side configuration must be specified clearly. Typical sides include:

- Metallized side (Met side): carries aluminum layer; responsible for reflectivity and contributes to barrier.

- Opposite side: may be corona-treated for printing/lamination adhesion, or configured as heat-sealable (HS) depending on grade.

A common converting failure is not ”bad film,” but wrong-side usage—printing on the wrong side, applying adhesive to an untreated side, or sealing against a surface that was not designed as the seal interface. A robust technical data sheet and purchase order should always define side mapping as A/B sides.

2) Key Properties and What They Mean in Use

2.1 Barrier properties: WVTR and OTR are not ”just numbers”

Buyers often request WVTR (water vapor transmission rate) and OTR (oxygen transmission rate), but these values are meaningful only when the test conditions and measurement basis are clear. In engineering procurement, it’s recommended to specify:

- Whether the target is for film-only or for finished laminate

- Temperature and humidity conditions

- Sampling plan and acceptance criteria (range, not a single number)

ISO water-vapour transmission test method for plastic film

ISO gas-transmission test method for plastic film

Keep these two references limited to one short sentence each (as above) so the page reads like an engineering guide, not an SEO link farm. Mentioning ISO once in the context of test methods is natural and credible.

2.2 Mechanical strength: why MD/TD balance matters

A metallized film that looks great but runs poorly is not a good solution. Tensile strength and elongation balance affect:

- Web handling at high line speeds (wrinkle control)

- Slitting behavior and edge stability

- Tension windows during lamination

- Risk of telescoping, starring, or blocking during storage

Typical values you provided (reference examples):

- Tensile strength (MD/TD): 142/255 MPa

- Elongation at break (MD/TD): 173/50%

These are useful as baseline indicators for converting suitability, but final performance depends on thickness selection and whether the film is designed for higher stiffness or higher toughness.

2.3 Metallic appearance: reflectivity is sensitive to micro-damage

The metallic brilliance of metallized BOPP is an advantage, but it also means defects become more visible:

- Fine scratches on the Met side create dull streaks

- Wrinkles create reflectivity distortion after lamination

- Metallization non-uniformity can appear as ”cloudy”or ”banded” effects

Therefore, the packaging method (pallet, corner protection, wrap, humidity control) and roll handling are not secondary details; they directly affect yield.

3) Typical Technical Data

The following typical values are consistent with the content you provided and can be presented as “typical” rather than guaranteed unless your supply agreement specifies tighter tolerances:

Typical values (reference for 15/18/20 μm):

- Thickness: 15, 18, 20 μm

- Tensile strength (MD/TD): 142/255 MPa

- Elongation at break (MD/TD): 173/50 %

- Sheet resistance indicator (metal layer): ~1.32 Ω

- WVTR: 0.5 g/(m²·24h)

- OTR: 1.0 cm³/(m²·24h)

Supply parameters (reference):

- Thickness range: 15–70 μm

- Width: ≤3200 mm

- Roll diameter: ≤800 mm

- MOQ: 1000 kg

- Core: 3″ / 6″

- Packaging: woven bag + pallet

- Certificates: RoHS, FDA (as declared for relevant grades)

A professional solution page should also state that final results depend on the laminate structure, adhesive system, sealing layer, and process conditions.

4) Selecting OD or Sheet Resistance

To avoid arguments like ”the film looks different from last shipment,” engineers often specify a metallization control metric. The two most common are Optical Density (OD) and sheet resistance (Ω).

4.1 Optical Density (OD): practical appearance + barrier indicator

OD is frequently used as a proxy for metallization strength. As OD increases, metallization typically becomes more continuous, which can correlate with improved barrier trend and higher reflectivity trend. However, OD is not a direct WVTR/OTR guarantee. It should be used as a process control parameter rather than the only acceptance criterion.

4.2 Sheet resistance (Ω): continuity indicator

Lower Ω generally indicates a more continuous metal layer (better conductivity), which often correlates with stronger barrier trend. The reference value you listed (1.32 Ω) can be described as a typical target point for certain packaging applications, while still allowing a defined acceptable range.

4.3 Procurement recommendation: specify ranges, not single points

To reduce disputes, specify ranges and uniformity expectations, for example:

- Sheet resistance target range: 0.8 to 2.5 Ω

- Cross-web uniformity: measured at multiple points

- Visual defect limits: pinholes, scratches, streaks

5) Side Mapping : The Critical Conversion Detail

Many quality complaints originate from side mapping confusion. A strong purchase order should define:

- Which side is metallized

- Which side is corona-treated (and target dyne at shipment)

- Whether one side is heat-sealable

- Winding orientation (A-in / A-out)

- Web direction if relevant to printing

5.1 Typical configurations

Configuration A: Printing + lamination (common)

- Corona-treated side used for printing and/or adhesive lamination

- Metallized side positioned for appearance or barrier within laminate

Configuration B: Appearance-forward structures

- Metallized side faces outward in the final laminate for premium metallic look

- Requires abrasion-resistant over-laminate or protective layer if handling is rough

Configuration C: One-side heat seal option

- Some grades offer a heat-sealable opposite side; alternatively, heat seal is achieved through a sealant layer such as CPP/PE in the laminate

5.2 Practical spec language (reduces errors)

Use clear mapping such as:

- Side A = Metallized (Met)

- Side B = Corona-treated

- Winding = A-in (or A-out)

- Intended use = printing (gravure/flexo) + lamination (solvent/solventless/extrusion)

This prevents ”we assumed the opposite” problems during converting.

6) Printing & Lamination Compatibility (Real Converting Considerations)

6.1 Printing: wetting and adhesion fundamentals

Metallized BOPP commonly runs on gravure and flexographic systems. Practical success depends on:

- Surface energy (dyne) at the point of printing

- Ink system selection (solvent or water-based)

- Drying efficiency and solvent retention control

- Print coverage effects on barrier (dense coverage can change overall laminate behavior)

Dyne levels tend to decline over time due to surface aging. A converting plan should consider the time from film receipt to printing/lamination and whether re-treatment is acceptable.

6.2 Lamination: solvent vs solventless vs extrusion

Solvent-based lamination

- Often offers broad process window and strong bond performance

- Requires careful solvent residue management and adequate drying

Solventless lamination

- Efficient and widely used for modern packaging

- More sensitive to mixing ratio accuracy, coat weight uniformity, and cure time

- Incomplete cure can lead to weak bond, poor heat resistance, or barrier inconsistency

Extrusion lamination

- Suitable for specific structures requiring additional stiffness or specialized interfaces

- Requires careful control of heat history and web tension

- Risk of shrinkage or distortion if process conditions are aggressive

6.3 Bond integrity: the real barrier is the final package

Even if film WVTR/OTR data is excellent, real-world barrier can fail due to:

- Adhesive under-application or non-uniform coating

- Cure not completed (especially in humid or cold environments)

- Seal channel leakage (tiny pathways at seals)

- Wrinkles or trapped air that create micro-channels

Therefore, best practice is to verify barrier at the laminate level and, for high-value products, at the finished package level.

7) Application Solutions

7.1 Food packaging (snacks, dry goods, frozen foods)

Metallized BOPP is frequently used when packaging requires:

- Improved oxygen/moisture barrier trend for shelf-life protection

- Light shielding for sensitive ingredients

- Premium shelf appearance and consistent gloss

- Good mechanical robustness for distribution stress

Typical structure examples (illustrative):

- Metallized BOPP / adhesive / PE or CPP sealant

- Metallized BOPP / adhesive / BOPP (appearance + stiffness; may require sealant elsewhere)

For frozen foods and aggressive storage conditions, the converting team should validate heat-seal performance and cold-crack resistance at the laminate level.

7.2 Pharmaceutical packaging

Where used for moisture protection and appearance, the key is documentation clarity:

- Confirm whether the film is intended for primary contact or secondary packaging

- Provide certificates as required by the target market

- Validate barrier performance in the final laminate system

7.3 Cosmetic packaging

Cosmetics often demand high appearance consistency. Metallized BOPP can provide:

- Metallic visual appeal and premium branding effect

- Adequate barrier trend for many dry cosmetic formats

- Good printability when side mapping and dyne are correctly specified

7.4 Electronics packaging

Electronics packaging often focuses on moisture protection during transport and storage. Metallized BOPP can serve as a barrier layer in a laminate where:

- Moisture ingress is a risk for components

- Appearance is secondary to functional packaging

- Seal integrity and handling damage resistance are critical

7.5 Industrial product packaging

Industrial components often require:

- Tear resistance and puncture tolerance

- Moisture barrier trend

- Stable converting and fast packing-line performance

Metallized BOPP can be a pragmatic choice, especially when the packaging is laminated to a tougher layer or combined with structures designed for high handling stress.

8) Quality Control Plan

A solution page that includes a realistic QC plan is more credible to international buyers than purely promotional claims.

8.1 Incoming inspection

- Thickness verification (multi-point)

- Width and roll diameter check

- Visual inspection under standardized lighting: scratches, pinholes, wrinkles, streaks

- Metallization control check: OD or sheet resistance sampling

- Surface energy (dyne) check on treated side

- Core integrity and slit edge quality

8.2 In-process converting controls

- Tension profile monitoring to prevent wrinkles and metallization abrasion

- Web guiding stability and edge-trim dust control

- Adhesive coat weight verification and cure schedule control

- Seal validation: seal strength, seal integrity, leak tests where relevant

8.3 Release criteria

Define what is acceptable in measurable terms:

- Acceptable OD/Ω range

- Allowable defect count per area or per roll length

- Dyne minimum at shipment and/or at conversion

- Roll hardness range and winding quality indicators

9) Failure Modes & Troubleshooting

Including a short troubleshooting section reduces buyer anxiety and demonstrates technical maturity.

9.1 Common issues and typical root causes

Issue: Poor ink adhesion

- Dyne too low or aged surface

- Printing on wrong side

- Surface contamination from handling

- Ink system mismatch or inadequate drying

Issue: Delamination / low bond strength

- Adhesive coat weight insufficient

- Incorrect mixing ratio (solventless)

- Incomplete curing time

- High humidity/low temperature affecting cure kinetics

- Metallized surface abrasion reducing effective bonding

Issue: Barrier lower than expected

- Seal leakage channels in final package

- Wrinkles or air entrapment creating micro-leak paths

- Metallization pinholes or handling damage

- Lamination defects, uneven adhesive

Issue: Appearance cloudiness or streaks

- Metallization non-uniformity

- Abrasion or pressure marks during packing/transport

- Wrinkles induced during converting

- Excessive tension or poor winding quality

A practical solution guide should emphasize that many failures are not ”film-only issues,” but system issues across converting and packaging.

10) Sustainability and Recycling

Metallized BOPP can be recyclable in certain streams, but recycling is strongly affected by laminate structure and local infrastructure. A responsible, non-marketing statement is:

- BOPP-based structures can be compatible with certain recycling routes when designed accordingly

- Metallization and multi-material laminates may reduce recyclability in some regions

- Buyers should align packaging design with local recycling capabilities and regulatory requirements

- Where recycling is a priority, evaluate mono-material laminate concepts and consult converting partners early

This balanced language avoids overpromising and is more credible to modern procurement teams.

11) Compliance Documentation

International buyers may request documentation for market entry or customer audits. A realistic list includes:

- Technical Data Sheet (TDS) and Certificate of Analysis (COA)

- RoHS / REACH-related declarations as applicable

- Food-contact compliance support for relevant grades and intended use

- Additional third-party testing where required by the customer

For U.S.-oriented food packaging discussions, some buyers reference FDA frameworks. The key is to avoid broad claims and instead state that documentation can be provided upon request depending on the grade and intended use scenario.

12) Procurement Specification Template

A strong solution page should end with a procurement template that reduces back-and-forth emails and prevents wrong-side supply.

Core specification

- Film type: Metallized BOPP

- Thickness: 18 μm (15–70 μm available)

- Width: 1200 mm (≤3200)

- Roll OD: 600 mm (≤800)

- Core: 3″ / 6″

- MOQ: 1000 kg per spec

Metallization control

- OD target: 2.0–2.4 OR

- Sheet resistance: 0.8 to 2.5 Ω

- Cross-web uniformity: sampling points 5 points across web

Side mapping (mandatory)

- Side A: Metallized (Met)

- Side B: Corona-treated / Heat-seal / Untreated

- Target dyne (if treated): 40 dynes at shipment

- Winding: A-in / A-out

Converting and end-use

- Printing: gravure / flexo

- Lamination: solvent / solventless / extrusion

- Intended laminate structure

- Packaging application: food / pharma secondary / cosmetic / electronics / industrial

- Storage requirements: cool/dry, UV avoidance, FIFO

Quality and inspection

- Visual defect limits: ≤10 pinholes per m²; no continuous scratch >50 mm; no telescoping; no blocking

- Thickness tolerance: ±5%

- Acceptance sampling plan: AQL 1.0, General Inspection Level II

13) Practical FAQ

Is metallized BOPP food-contact safe?

Food packaging grades can be produced to meet applicable requirements when used as intended and when supported by documentation. Buyers should specify the target market and provide the intended laminate structure to confirm documentation needs.

Can metallized BOPP be heat-sealed directly?

Some grades include a heat-seal layer on one side; otherwise heat sealing is typically achieved through a sealant layer such as CPP/PE in the laminate.

How do I choose OD or sheet resistance?

OD is commonly used for quick metallization consistency and appearance trend control; sheet resistance provides a continuity indicator for the metal layer. Many buyers choose one metric plus visual defect limits to reduce disputes.

Any cautions for microwave use or metal detection?

Metallized structures are generally not suitable for microwave heating. The metal layer may affect metal detection systems, so validation on the packaging line is recommended.

How should rolls be stored?

Store in a cool, dry environment away from UV. Use FIFO. Surface energy can decline over time; convert within the agreed window or confirm whether re-treatment is permissible.