Introduction: The Film Industry Reaches a Turning Point for High-Quality Development, Equipment Upgrades Become the Key

Driven by the global “New Plastics Economy” initiative and domestic industrial upgrading policies, high-performance plastic films, as core materials in packaging, electronics, pharmaceuticals, agriculture, and other fields, are seeing market demand grow at a steady annual rate of 8.3%. Data shows that in 2024, the global biaxially oriented film market exceeded USD 32 billion, with high-end applications such as food packaging, battery separators, and electronic displays growing at rates exceeding 12%. However, the domestic film industry has long faced the structural contradiction of “insufficient high-end capacity and excess low-end capacity,” with gaps in core technologies and top-tier production equipment becoming key bottlenecks limiting enterprises from breaking through.

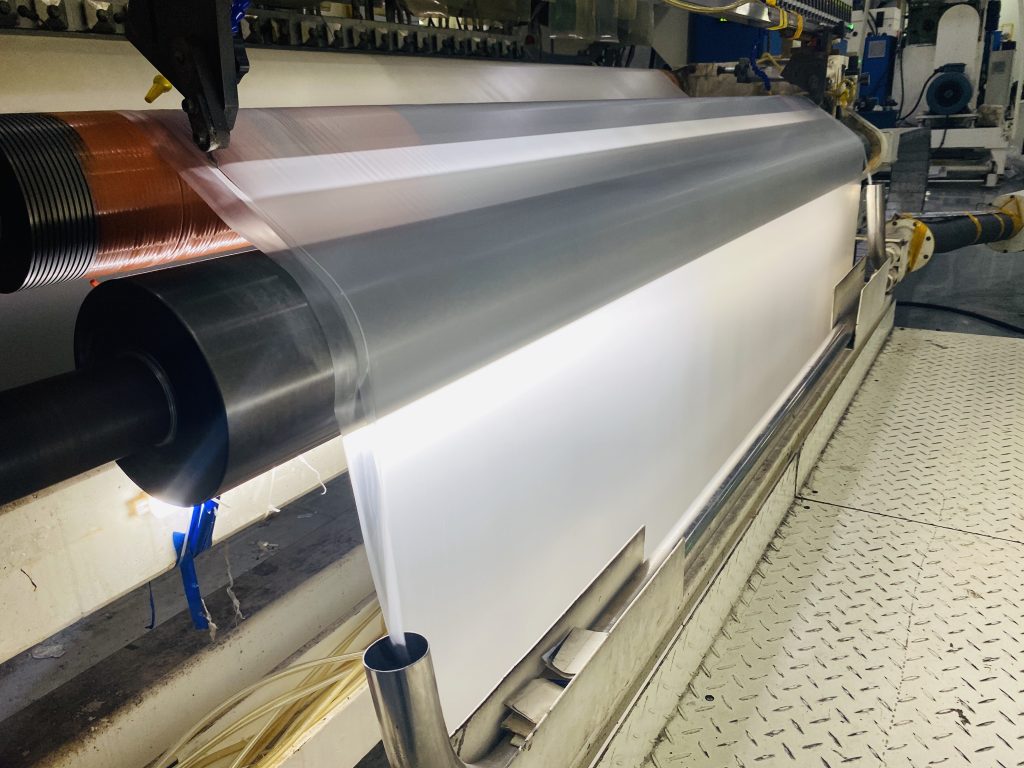

As a global leading supplier of high-performance film materials, Tradsark New Materials Co., Ltd. (Tradsark) has always adhered to the core strategy of “technology-driven innovation, quality-led market leadership.” To break the technological barriers of high-end film production and meet the rigorous demands of global customers for high-performance, environmentally friendly films, Tradsark officially announces the strategic introduction of German Brückner Maschinenbau biaxially oriented film production lines. This move not only marks Tradsark’s manufacturing capabilities entering the international top tier but also injects new momentum into the high-quality development of the Chinese and global film industry.

I. Why Choose Brückner Maschinenbau? The “Golden Standard” of Global Biaxially Oriented Film Equipment

- Brückner Group: A Century of Industry Accumulation

Founded in 1949 and headquartered in Töging am Inn, Bavaria, Germany, Brückner Group is an absolute leader in the fields of film production, coating, and finishing equipment. Among them, Brückner Maschinenbau, as the group’s core business segment, focuses on the R&D and manufacturing of biaxially oriented film production lines (BOPP, BO-PET, BO-PA, etc.), and with over 70 years of technological accumulation, has become synonymous with high-end film equipment worldwide.

Today, Brückner Maschinenbau’s equipment has been exported to more than 80 countries and regions, holding over 40% of the global biaxially oriented film production line market, far exceeding the industry average. From international giants like DuPont and Mitsubishi Chemical to domestic leading enterprises, the core production lines of most high-end film manufacturers worldwide come from Brückner. Its long-term market leadership stems from the pursuit of technological innovation, rigorous quality control, and precise industry trend forecasting.

- Core Advantages: Technology, Efficiency, and Environmental Sustainability

(1) Technological Leadership: Setting the “Precision Ceiling” for Biaxially Oriented Film Production

Brückner Maschinenbau’s production lines adopt the world’s first “linear motor synchronous stretching technology,” achieving millisecond-level synchronous control of machine direction (MD) and transverse direction (TD) stretching, with a stretching precision error within ±0.1%. This extreme precision ensures uniform film thickness (deviation ≤2%), stable mechanical performance (tensile strength fluctuation ≤3%), and consistent optical properties (haze deviation ≤0.2%), fully meeting the demanding performance requirements of high-end applications.

For example, its flagship BOPP film production line has a web width of up to 10.4 meters, a maximum production speed of 700 meters per minute, and an annual output of up to 35,000 tons per line—1.8 times that of traditional equipment. Additionally, the line supports “multi-product flexibility,” allowing quick switching between standard packaging films, high-transparency films, heat-sealable films, metallized base films, and more within 2-3 hours, greatly enhancing production flexibility.

For BO-PET film production lines, Brückner innovatively adopts a “dual stretching frame design,” solving industry challenges of PET materials being prone to crystallization and wrinkling under high-temperature stretching. The resulting BO-PET films achieve tensile strength up to 250 MPa, elongation at break controlled at 15-20%, and thermal shrinkage ≤1% (150°C, 30 minutes), fully suitable for applications in electronics displays, battery separators, and other high-tech fields.

(2) High Efficiency and Energy Saving: The “Core Engine” for Cost Reduction and Efficiency Improvement

Amid the global energy crisis and increasing environmental pressure, Brückner Maschinenbau equipment incorporates “high efficiency and energy saving” throughout the design process. By using advanced heating systems, waste heat recovery devices, and variable frequency energy-saving motors, the unit energy consumption of the production lines is reduced by over 30% compared to traditional equipment. For a BOPP production line with an annual output of 30,000 tons, annual electricity savings can reach approximately 2.8 million kWh, natural gas consumption can be reduced by around 1.2 million cubic meters, equating to over RMB 2 million in annual cost savings.

Moreover, the automation level reaches 95%, equipped with AI visual inspection systems, intelligent closed-loop control, and automatic alignment systems, enabling fully automated control from raw material input, stretching, thickness inspection to winding and packaging, managed by only 3-5 operators—reducing labor costs by 60% compared to traditional equipment. The mean time between failures (MTBF) exceeds 8,000 hours, and maintenance intervals extend to 12 months, greatly reducing downtime losses.

(3) Green and Sustainable: Aligning with the “Future Trend”

Brückner Maschinenbau consistently integrates environmental protection into equipment R&D, achieving green production across multiple dimensions:

- Raw material utilization: Through precise formulation control and optimized forming processes, film scrap rates are reduced to below 1.5%, well below the industry average of 5%;

- Zero pollutant emissions: Closed production systems ensure exhaust gases are treated with activated carbon adsorption plus catalytic combustion, with VOC emissions ≤10mg/m³, meeting the strictest EU environmental standards;

- Recyclable design: Core components feature modular designs, with 85% of parts recyclable, aligning with the circular economy concept.

These environmental advantages not only help enterprises reduce compliance costs but also meet global customers’ sustainability requirements, supporting product entry into international high-end markets.

II. Tradsark’s Strategic Layout: Empowering the Entire Industry Chain with Top-Tier Equipment

- Filling the High-End Capacity Gap and Breaking Import Dependence

The domestic high-end film market (such as electronic-grade BO-PET films, battery separator substrates, and pharmaceutical-grade BO-PA films) has long relied heavily on imports, accounting for over 60% of demand, mainly due to domestic enterprises’ outdated production technology unable to meet high-end film performance requirements.

The newly introduced Brückner Maschinenbau production lines at Tradsark cover the three core product series: BOPP, BO-PET, and BO-PA, capable of producing films with thicknesses ranging from 20μm to 120μm with high precision. Electronic-grade BO-PET films achieve light transmittance above 92%, haze ≤1.0%, and surface roughness Ra ≤0.02μm, meeting the requirements for polarizers, flexible circuit boards, and other electronic applications. Pharmaceutical packaging BO-PA films have oxygen transmission ≤5 cc/(m²·day·atm) and water vapor transmission ≤1 g/(m²·day), effectively extending drug shelf life up to 36 months, meeting international pharmacopeia standards.

By introducing this equipment, Tradsark will add 50,000 tons of high-end film annual capacity, with battery separator substrates and electronic display films accounting for 40% of output, expected to replace approximately 30,000 tons/year of imported products, significantly reducing domestic high-end film import dependence and lowering procurement costs for downstream enterprises.

- Expanding Application Boundaries: Comprehensive Coverage from Traditional Packaging to High-Tech Fields

As a global leading film materials supplier, Tradsark’s products are widely used in food packaging, agriculture, construction, and other traditional fields. With Brückner equipment, Tradsark will further expand high-end application scenarios, transitioning from a “traditional film supplier” to a “high-tech film solutions provider.”

(1) Food and Pharmaceutical Packaging: Dual Upgrade of Safety and Preservation

In food packaging, Tradsark will produce high-barrier BOPP/BO-PET composite films with oxygen transmission ≤3 cc/(m²·day·atm) and water vapor transmission ≤0.8 g/(m²·day), extending shelf life of products like chips and coffee beans by over 12 months—50% improvement over traditional packaging. These films use food-grade raw materials and eco-friendly additives, certified under FDA and EU 10/2011 standards.

In pharmaceutical packaging, BO-PA films provide excellent barrier properties, chemical resistance, and mechanical strength, ideal for tablets and capsules. Tradsark’s BO-PA films will meet ISO 15223 and YBB standards, ensuring moisture-proof, oxidation-proof, and UV-protective performance, enhancing product quality and shelf life.

(2) Electronics and New Energy: Empowering High-End Manufacturing with “Core Materials”

With rapid growth in electric vehicles, energy storage batteries, and electronic displays, demand for high-performance films is surging. Leveraging Brückner equipment, Tradsark will focus on:

- Battery separator substrates: Producing 6–12 μm BO-PET/BO-PP films with pore rates 35–45% and uniformity ≤0.5 μm, suitable for lithium-ion and sodium-ion battery insulation and gas permeability; post-coating, these films can become high-performance lithium battery separators, replacing imports and reducing costs in domestic new energy battery production.

- Electronic display films: Producing high-transparency, low-haze BO-PET films for polarizers, diffuser films, and brightness enhancement films, achieving ≥93% light transmittance, haze ≤0.8%, and surface flatness ≤0.01 mm/m, suitable for OLED and Mini LED high-end displays.

(3) Agriculture and Construction: Functional Upgrade with Green Sustainability

In agriculture, Tradsark will produce high-transparency, high-insulation, and aging-resistant BO-PET films with ≥90% light transmittance, 15% higher insulation than traditional PE films, and a lifespan exceeding 3 years, helping farmers increase crop yield by over 20% while reducing film replacement frequency and environmental pressure.

In construction, Tradsark will produce thermal insulation, soundproof, and fire-resistant composite films with thermal conductivity ≤0.03 W/(m·K), sound insulation ≥35 dB, and flame-retardant rating UL94 V-0, suitable for curtain walls, windows, and roof insulation, supporting green building development.

- Strengthening R&D Capabilities and Building Technological Barriers

In addition to production equipment, Tradsark has introduced Brückner’s laboratory-scale film stretching equipment, a compact, high-precision platform simulating industrial line stretching processes for full-process testing from raw material formulation and process parameters to product performance.

This lab equipment allows Tradsark’s R&D team to rapidly validate new formulations, optimize production parameters, and shorten new product development cycles—for example, degradable films and high-barrier films traditionally requiring 12–18 months can be developed in 6–8 months, greatly enhancing innovation efficiency.

Tradsark will also establish joint R&D with Brückner, sharing technical resources and market insights to develop new films that meet future market demands, building core technological barriers and consolidating leadership in the global high-performance film market.

III. Customer Value Upgrade: Tradsark and Partners’ “Win-Win New Ecosystem”

- Quality Assurance: Providing Customers with a “Reliable” Product Experience

In high-end manufacturing, product quality stability directly affects downstream production efficiency and competitiveness. Tradsark’s Brückner lines ensure production precision and full-process automation, keeping performance parameter variation below 3% and product pass rate at 99.99%. This quality reliability helps customers reduce waste, improve production efficiency, and mitigate quality risks.

For example, in food packaging, stable barrier performance ensures consistent shelf life; in electronics, uniform thickness and optical properties guarantee display and battery performance, enhancing end-user experience.

- Cost Optimization: Helping Customers Achieve “Cost Reduction and Efficiency Improvement”

Leveraging Brückner equipment’s high efficiency, Tradsark optimizes production costs while enhancing quality. High output and low energy consumption reduce unit production cost, and scale production with integrated supply chain ensures competitive pricing.

Tradsark also provides customized solutions, optimizing film formulations and processes to reduce downstream processing costs. For pharmaceutical packaging, high-barrier BO-PA films can meet barrier requirements without extra aluminum foil, reducing packaging costs by over 30%.

- Service Upgrade: Full Lifecycle “Thoughtful Guarantee”

Tradsark has established a full lifecycle service system:

- Pre-sale consultation: Technical team provides film selection and application design guidance.

- In-sale support: Free sample testing and process debugging ensure compatibility with customer equipment.

- After-sale support: 24-hour global technical hotline with ≤1-hour average response, 95% issues solved on first contact; major markets have warehousing centers for fast delivery, shortening procurement cycles.

Additionally, Tradsark offers “supply chain financial services” to core customers, providing flexible payment and credit terms, easing financial pressure, and supporting production scale-up.

IV. Industry Impact: Leading China’s Film Industry Toward “High-End, Intelligent, and Green” Transformation

Tradsark’s introduction of Brückner top-tier production lines is not only a strategic upgrade for the company but also has far-reaching effects on China’s and the global film industry:

- Promoting Industry Upgrade: Enhancing China’s Global Competitiveness in Film

Historically, China’s film industry has focused on mid- to low-end products, positioned passively in the global chain. Tradsark’s equipment upgrade sets a benchmark, encouraging more domestic companies to invest in high-end equipment and core technology, promoting a shift from “scale expansion” to “quality enhancement,” increasing China’s voice in the global industry chain.

Improved domestic high-end film capacity will also reduce downstream manufacturers’ import dependence, strengthen supply chain resilience, and support high-quality development of Chinese manufacturing.

- Supporting “Dual Carbon” Goals: Promoting Green Transformation of the Film Industry

The energy-saving advantages of Brückner equipment align with Tradsark’s green development philosophy. Equipment upgrades will reduce CO₂ emissions by about 5,000 tons annually and save approximately 2,000 tons of standard coal. This green production model sets an industry benchmark, encouraging other enterprises to adopt eco-friendly equipment and processes, contributing to national “dual carbon” goals.

Tradsark will also increase R&D and production of degradable and recycled films, promoting a circular economy, reducing plastic pollution, and achieving sustainable development.

- Fostering Technological Innovation: Stimulating Industry Innovation Vitality

Collaboration with Brückner introduces global leading technology and innovation concepts, stimulating domestic industry innovation. Enterprises will learn and improve R&D and manufacturing capabilities, while intensified market competition will drive more innovation investment, developing proprietary core technologies and products, elevating overall industry technical level.

V. Future Outlook: Tradsark’s Path to Becoming a “Global Film Leader”

At this new development stage, Tradsark will leverage the Brückner production line introduction to continuously advance “technological innovation, quality upgrading, and service optimization,” steadily moving toward the goal of becoming a “global leader in high-performance films.”

In the next three years, Tradsark plans to expand production further, adding two more Brückner lines to reach 150,000 tons of annual high-end film capacity, becoming one of the largest global high-performance film suppliers. R&D investment will increase to 8% of annual revenue, focusing on degradable films, new energy films, electronic display films, and other frontier areas, aiming to double the number of core technology patents within five years.

In market expansion, Tradsark will establish branches and warehousing centers in Europe, North America, Southeast Asia, and other regions, enhancing global service capabilities and providing international customers with high-quality films and solutions.

Additionally, Tradsark will actively fulfill social responsibility, participate in industry standard-setting, plastic pollution mitigation, and sustainability initiatives, building a global brand image of “technology leadership, superior quality, environmental sustainability, and social responsibility.”

Conclusion: With Technology as Wings and Quality as Foundation, Creating a New Future for the Film Industry

Amid global industrial transformation and technological innovation, Tradsark remains committed to “creating value for customers and contributing to society.” The introduction of Brückner Maschinenbau’s top-tier production lines is a crucial step in Tradsark’s strategic upgrade and a solemn commitment to global customers—delivering globally leading technology, exceptional quality, and efficient, attentive service to empower partners and co-create a win-win ecosystem.

In the future, Tradsark will continue to focus on high-performance films, drive development through innovation, earn trust through quality, lead with responsibility, and, together with global partners, promote the high-end, intelligent, and green transformation of the film industry, contributing more to a better life for humanity.

If you are interested in Tradsark’s high-performance film products or customized solutions, please feel free to contact us to explore the infinite possibilities of film technology together!