Food packaging films are a foundational material in the modern food industry, combining polymer science, process engineering, and food safety management. From raw material selection to orientation, coating, metallization, and quality control, food packaging films are engineered to meet strict functional and regulatory requirements. This article provides a technically focused, non-promotional overview of food packaging film suppliers and manufacturers, with particular attention to film structures, performance parameters, and production technologies used in global markets.

What Defines a Food Packaging Film Supplier & Manufacturer

A food packaging film manufacturer is an industrial producer that converts polymer resins into functional films suitable for direct or indirect food contact. A supplier may be the manufacturer itself or an entity responsible for distribution, technical support, and logistics. In many cases, large-scale manufacturers operate as both producers and suppliers.

Manufacturers are responsible for:

- Polymer formulation and extrusion

- Film orientation and surface treatment

- Barrier enhancement through metallization or coating

- Quality assurance and food safety compliance

- Roll finishing, slitting, and packaging

Suppliers ensure:

- Stable availability and specification consistency

- Documentation for regulatory compliance

- Technical coordination with converters and food processors

Core Technical Functions of Food Packaging Films

Mechanical Performance

Mechanical properties determine how a film behaves during packaging, transport, and storage. Key parameters include:

- Tensile strength (MD/TD)

- Elongation at break

- Tear resistance

- Puncture resistance

Biaxially oriented films such as BOPP and BOPET exhibit significantly higher tensile strength and dimensional stability compared to non-oriented films, enabling downgauging without compromising performance.

Barrier Properties

Barrier performance is central to food packaging film design. Commonly measured values include:

- Oxygen Transmission Rate (OTR)

- Water Vapor Transmission Rate (WVTR)

- Light transmission and opacity

Barrier requirements vary by food type. For example, dry snacks require moisture barriers, while fatty foods require oxygen and light protection to prevent oxidation.

Thermal and Seal Performance

Thermal behavior determines compatibility with packaging machinery and processing conditions. Important characteristics include:

- Heat seal initiation temperature

- Seal strength and hot tack

- Shrinkage and dimensional stability under heat

CPP and PE films are frequently used as sealant layers due to their stable sealing windows.

Polymer Materials Used in Food Packaging Films

BOPP (Biaxially Oriented Polypropylene Film)

BOPP films are produced through sequential or simultaneous biaxial stretching. Technical advantages include:

- High stiffness-to-weight ratio

- Low density for cost efficiency

- Good moisture barrier

- Excellent printability after surface treatment

Common variants include transparent, pearlized, matte, and metallized BOPP.

BOPET (Biaxially Oriented Polyester Film)

BOPET films offer superior thermal resistance and dimensional stability. Typical technical properties include:

- High tensile modulus

- Stable performance at elevated temperatures

- Good gas barrier compared to polyolefins

They are widely used in laminates for retort, frozen, and high-speed packaging applications.

CPP (Cast Polypropylene Film)

CPP films are cast-extruded and not oriented, resulting in:

- High clarity

- Excellent seal strength

- Good flexibility

CPP is commonly used as the inner layer in multi-layer food packaging structures.

Polyethylene (PE) Films

PE films, including LDPE and LLDPE, are valued for:

- Impact resistance at low temperatures

- Broad sealing range

- Flexibility

They are frequently used in frozen food and fresh produce packaging.

Metallized Films

Metallized films are produced by depositing an aluminum layer (typically 300–500 Å) via vacuum metallization. Technical benefits include:

- Significantly reduced OTR and WVTR

- Light and UV barrier

- Improved shelf-life performance

Metallized BOPP and metallized PET are widely used in snack, coffee, and confectionery packaging.

Film Manufacturing Technologies

Extrusion and Orientation Technology

Film extrusion begins with resin melting and filtration, followed by sheet or bubble formation. Biaxial orientation aligns polymer chains, improving strength and clarity. Equipment quality and process control directly affect film uniformity.

Surface Treatment

Corona or plasma treatment increases surface energy, improving ink adhesion and lamination strength. Treatment levels are monitored to maintain consistency over shelf life.

Vacuum Metallization

In PVD metallization, aluminum wire is vaporized under vacuum and condensed onto the film surface. Control of vacuum pressure, deposition rate, and cooling is critical to achieving uniform barrier performance.

Coating and Lamination

Barrier coatings such as acrylic, PVDC, or water-based coatings may be applied to enhance performance. Lamination combines multiple films to achieve tailored functionality.

Quality Control and Testing Parameters

Food packaging film manufacturers conduct routine testing, including:

- Thickness and basis weight

- Tensile and elongation testing

- OTR and WVTR measurement

- Seal strength testing

- Optical properties (haze, gloss)

Traceability systems link finished rolls to raw material batches and production conditions.

Food Safety and Regulatory Compliance

Food packaging films must comply with food contact regulations such as FDA (21 CFR), EU Regulation No. 10/2011, and regional standards in Latin America and Asia. Compliance involves migration testing, material declarations, and controlled manufacturing environments.

Global Manufacturing and Supply Landscape

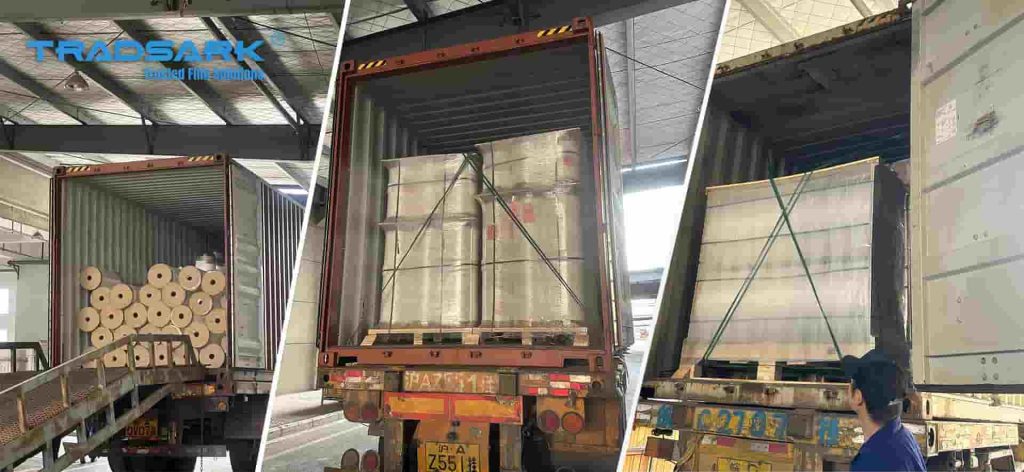

Major food packaging film production regions include Asia, Europe, and North America. China has developed extensive capacity supported by advanced equipment and integrated supply chains. Manufacturers such as Tradsark New Materials (Weifang) Co., Ltd. operate multiple production lines for BOPP, BOPET, CPP, and metallized films, supplying food-grade materials to international markets under standardized quality systems.

Sustainability and Technical Innovation Trends

Downgauging and Material Efficiency

Improved orientation technology enables thinner films with equivalent mechanical performance.

Mono-Material Structures

All-PP and all-PE laminates improve recyclability by reducing material complexity.

Process Energy Optimization

Modern production lines focus on energy efficiency, waste reduction, and emissions control.

Selecting a Food Packaging Film Supplier

Technical evaluation criteria typically include:

- Specification repeatability

- Testing capability

- Compliance documentation

- Production scale and lead time

- Long-term supply reliability

Frequently Asked Questions (FAQ)

1. What makes a film suitable for food contact?

Food contact suitability depends on material purity, controlled processing, and regulatory compliance.

2. How is OTR different from WVTR?

OTR measures oxygen permeability, while WVTR measures moisture transmission.

3. Why are biaxially oriented films stronger?

Orientation aligns polymer chains, increasing tensile strength and stiffness.

4. Are metallized films recyclable?

Recyclability depends on base material and local recycling infrastructure.

5. What thickness ranges are common for food films?

Typical ranges are 12–50 microns, depending on application.

6. How does corona treatment affect printing?

It increases surface energy, improving ink adhesion.

7. Can one film structure fit all food products?

No, film structures are tailored to specific food requirements.

8. How long can food packaging film be stored?

Most films have a shelf life of 6–12 months under proper storage.

9. What testing is done before shipment?

Mechanical, barrier, and visual inspections are standard.

10. How does metallization improve barrier performance?

The aluminum layer reduces gas and light transmission.

11. What is hot tack strength?

It measures seal strength while still hot during packaging.

12. Why is dimensional stability important?

It ensures consistent performance on high-speed packaging lines.

13. Are coatings an alternative to metallization?

Yes, coatings can enhance barrier properties without metal layers.

14. What role does supplier testing capability play?

In-house testing improves consistency and technical support.

15.How do buyers verify supplier reliability?

Through audits, documentation review, and long-term performance evaluation.

Conclusion

Food packaging film suppliers and manufacturers operate at the intersection of material science, engineering, and food safety. A technical understanding of film materials, processing technologies, and performance parameters is essential for informed sourcing decisions. As regulatory and sustainability requirements continue to evolve, technically capable and transparent manufacturers remain central to the global food packaging ecosystem.