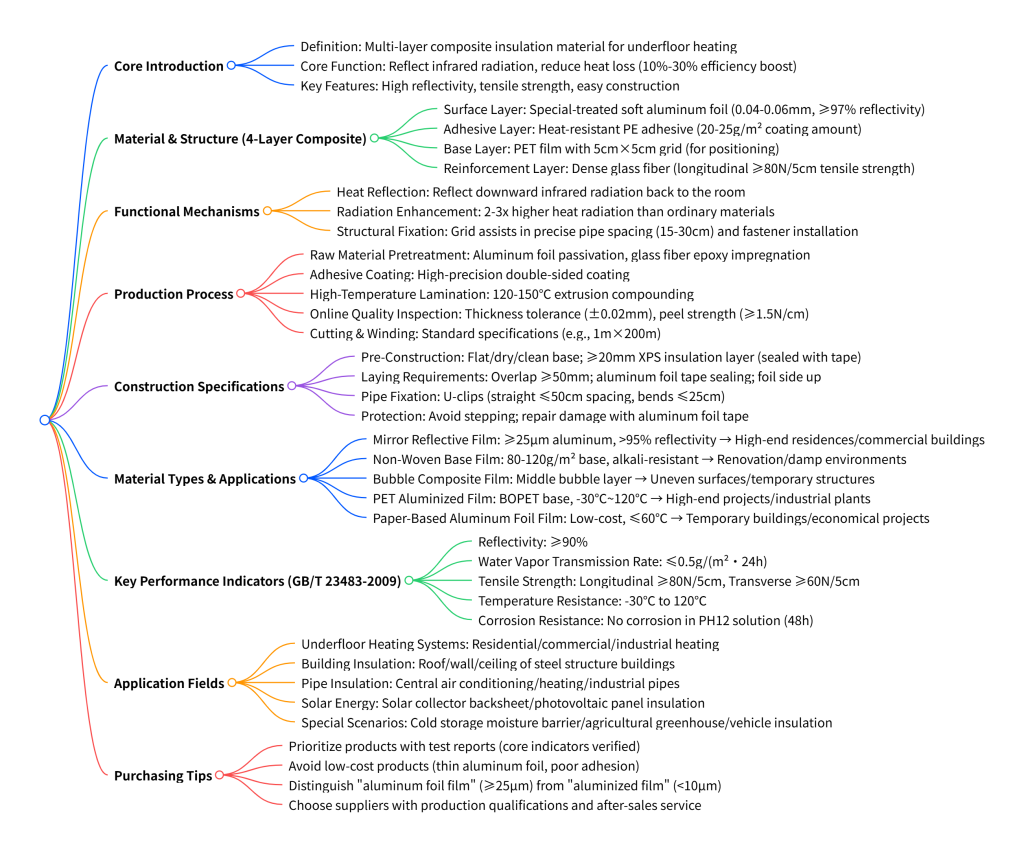

In low-temperature underfloor heating systems, reflective foil is an indispensable core insulation material. Through scientifically designed composite structures and infrared reflection technology, it significantly reduces heat loss downward, increasing heating efficiency by 10%-30% and directly affecting energy-saving performance and user experience. With the rapid development of the underfloor heating market, both consumers and installers increasingly require knowledge about material selection, performance requirements, and installation standards. This article provides a comprehensive analysis of underfloor heating reflective foil from seven perspectives: material structure, functional principle, production process, installation standards, material types, performance indicators, and application scenarios, offering professional reference for selection and installation.

1. Materials and Structure of Underfloor Heating Reflective Foil: Four-Layer Scientific Design

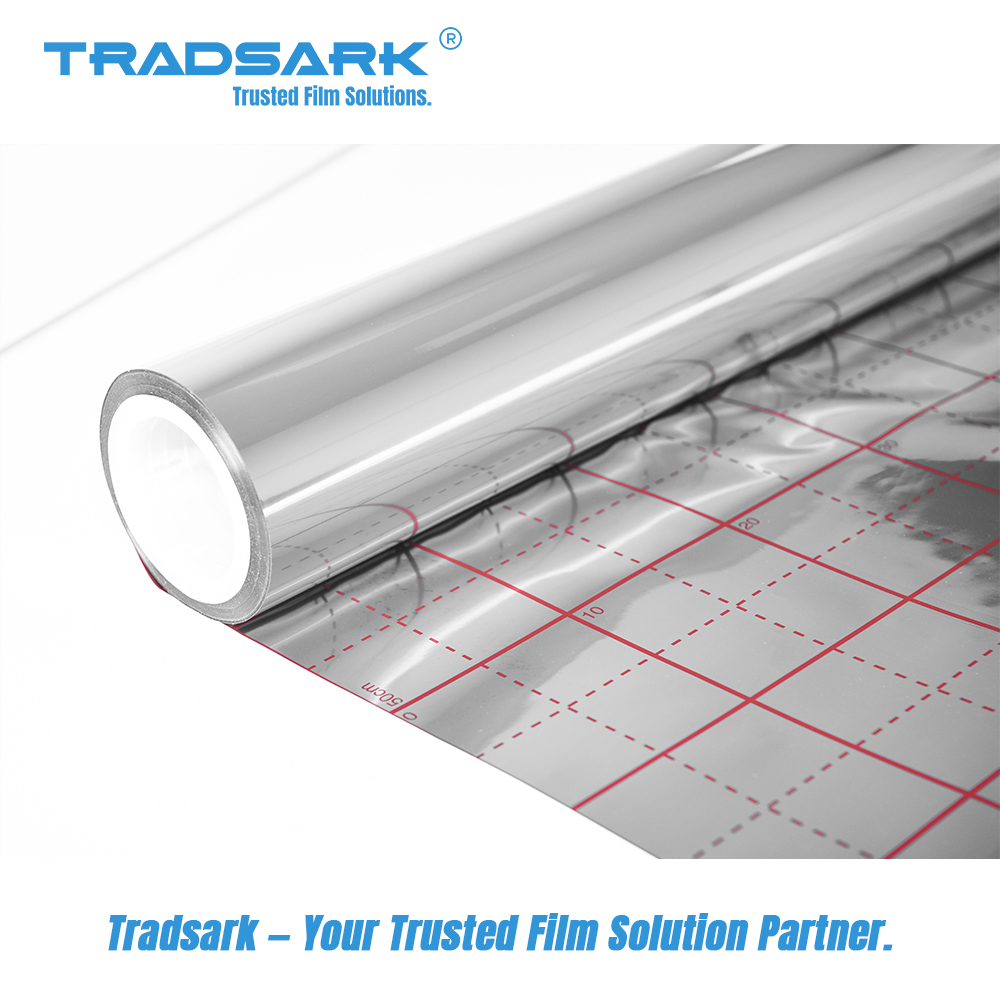

Reflective foil is not a single material but a composite product made of multiple functional layers through high-temperature lamination. Its structural design directly determines core performance such as heat reflection, tensile strength, and installation adaptability. The industry’s mainstream reflective foil adopts a four-layer composite structure, where each layer serves a distinct purpose and works synergistically:

(1) Core Components and Functions

Top Layer:

The aluminum foil layer is the core functional layer of the reflective foil, made with high-vacuum aluminum plating, with thickness strictly controlled between 0.04-0.06 mm. The passivated aluminum surface is smooth and dense, with an infrared reflectivity of over 97%, efficiently reflecting infrared radiation from underfloor heating pipes and reducing heat conduction into the subfloor. Passivation also enhances corrosion resistance, preventing long-term oxidation failure.

Adhesive Layer:

Heat-resistant PE adhesive connects all layers. It must withstand high temperatures and have strong bonding. In production, a double-sided coating process is used, with precise coating weight of 20-25 g/m², ensuring it does not melt or drip during the 120-150℃ lamination process, forming a firm bond between aluminum foil, polyester film, and fiberglass, preventing delamination during use.

Base Layer:

Colored coordinate-marked polyester film (usually PET) serves as the support layer, providing heat resistance, tear resistance, and dimensional stability. The printed 5cm×5cm grid coordinates help installers quickly position and calculate pipe spacing, ensuring standardized installation.

Reinforcement Layer:

The woven fiberglass bottom layer enhances mechanical strength. Treated with epoxy resin, it bonds tightly with other layers. Tensile strength reaches industry standards: longitudinal ≥80N/5cm, transverse ≥60N/5cm, enabling resistance to installation stress such as stretching and nail fixing.

(2) Advantages of the Layered Structure

The four-layer design achieves “functional separation with synergistic enhancement”: aluminum foil reflects heat, polyester film maintains shape, fiberglass reinforces strength, and PE adhesive ensures firm bonding. This structure guarantees thermal insulation, prevents tearing or oxidation, and ensures easy installation and durability.

2. Functional Principles: Three Mechanisms for Efficient Heat Management

The energy-saving effect of reflective foil relies not only on reflection but on three synergistic mechanisms: thermal reflection, enhanced radiation, and structural fixation, which together improve heating efficiency and indoor comfort.

(1) Thermal Reflection: Reducing Heat Loss

Underfloor heating pipes emit heat, part of which conducts upward to indoor space, and part downward to the subfloor. The aluminum foil reflects downward infrared radiation back to the room, concentrating heat indoors. High-quality reflective foil reduces downward heat loss from 30%-40% to below 10%, significantly improving energy utilization.

(2) Radiation Enhancement: Accelerating Room Heating

Specially treated aluminum foil enhances thermal radiation, increasing radiative heat transfer 2-3 times faster than ordinary insulation. Rooms equipped with reflective foil reach the set temperature 15-30 minutes faster, providing rapid and comfortable heating.

(3) Structural Fixation: Ensuring Installation Accuracy

The printed grid on the foil acts as a positioning tool, allowing installers to maintain uniform pipe spacing (15-30 cm standard) and parallel alignment (deviation ≤2mm/m). It also provides clear points for U-shaped clips, stabilizing pipe installation and supporting subsequent floor finishing.

3. Production Process: High-Temperature Lamination and Precision Control

High-quality reflective foil requires strict process control and advanced technology. The main industrial method is direct high-temperature extrusion lamination.

(1) Key Production Steps

- Raw Material Pre-Treatment

- Aluminum passivation: forming dense oxide film for corrosion resistance and adhesive bonding.

- Fiberglass pre-impregnation: soaked in epoxy resin to improve bonding and mechanical strength.

- Polyester cleaning: remove dust, grease, and moisture via static and high-temperature treatment.

- Adhesive Coating

- Apply heat-resistant PE adhesive with high-precision coating, weight 20-25 g/m².

- High-Temperature Lamination

- Stack layers in order and laminate at 120-150℃ under pressure. Temperature and pressure must be strictly controlled to avoid deformation or weak bonding.

- Online Quality Inspection

- Thickness tolerance: ±0.02mm

- Peel strength: ≥1.5 N/cm

- Reflectivity: ≥90%

- Surface inspection: check for scratches, bubbles, or damage

- Cutting and Rolling

- Cut to common sizes (1m×200m, 1.2m×150m) and neatly roll for storage.

(2) Core Process Controls

- Temperature stability ±5℃

- Adhesive coating error ≤1g/m²

- Consistent material tension

- Clean production environment

4. Installation Standards: Ensuring Performance Through Compliance

Installation quality directly affects heating efficiency and product lifespan. The process should comply with JGJ 142-2012 “Technical Specification for Floor Radiation Heating”.

(1) Pre-Installation Preparation

- Surface: flat, dry, clean; deviation ≤3mm/2m.

- Insulation Layer: XPS board ≥20mm thick; joints ≤2mm, sealed with tape.

- Materials: check foil specification, aluminum tape, U-clips, tape measure, and cutter.

(2) Laying Procedures

- Coverage: extend 10-15 cm beyond wall; lap ≥50mm, sealed with ≥20mm aluminum tape.

- Grid Alignment: parallel to main axes; deviation ≤2mm/m. Adjust in irregular rooms.

- Sealing: all edges and corners sealed with aluminum tape, ensuring no gaps.

(3) Pipe Fixing and Protection

- Clip Spacing: straight ≤50cm, bends ≤25cm; clip vertically to avoid foil damage.

- Protection: avoid stepping on foil; use protective boards during backfilling. Repair any damage with tape; replace large damaged areas.

(4) Common Installation Mistakes

- Using regular tape instead of aluminum tape

- Insufficient overlap width

- Aluminum side facing down

- Ignoring corner sealing

5. Material Types: Five Categories and Their Applications

Reflective foils are classified into five types based on substrate, process, and performance:

| Type | Key Features | Advantages | Suitable Applications |

|---|---|---|---|

| Mirror Foil | Aluminum ≥25μm, reflectivity >95%, corrosion-resistant | High reflection, durable, strong | High-end residential, commercial buildings |

| Nonwoven Base | 80-120 g/m² nonwoven, excellent alkali resistance | Flexible, tear-resistant, easy to fit uneven floors | Renovation, uneven floors, humid areas |

| Bubble Pad Composite | Bubble layer 5-10mm, aluminum & PET layers | Reflects and insulates, easy to install | Temporary buildings, budget heating |

| PET Aluminum Foil | BOPET substrate, vacuum aluminum, composite with fiberglass | Heat-resistant, dimensionally stable, high reflectivity ≥92% | High-end residential, industrial floors |

| Paper Base Aluminum | Paper substrate, thin aluminum | Low cost, easy to lay | Temporary structures, short-term use |

Material Selection Tips:

- Long-term use: Mirror or PET aluminum foils

- Uneven floors: Nonwoven or bubble pad foils

- Budget: Paper-based foil

- Humid areas: Nonwoven base foil

6. Performance Indicators: Key Metrics Determining Quality

| Indicator | Standard (GB/T 23483-2009) | Interpretation |

|---|---|---|

| Reflectivity | ≥90% | Higher reflectivity = better energy saving |

| Moisture Permeability | ≤0.5 g/m²·24h | Better moisture resistance |

| Tensile Strength | L ≥80N/5cm, T ≥60N/5cm | Withstands installation stress |

| Peel Strength | ≥1.5N/cm | Layers remain bonded |

| Temperature Range | -30℃ to 120℃ | Wide environmental adaptability |

| Corrosion Resistance | PH12, 48h | Suitable for humid or alkaline areas |

| Thickness Tolerance | ±0.02mm | Consistent overall performance |

Selection Tips:

- Check reflectivity visually or with flashlight

- Test tensile strength and peel strength manually

- Verify moisture resistance via product labeling or test reports

- Avoid low-cost foils with recycled or thin aluminum

7. Applications Beyond Underfloor Heating

Reflective foil is multifunctional, applied in:

(1) Core: Low-Temperature Underfloor Heating

- Residential, commercial, and industrial floors

- Installed between insulation layer and heating pipes

- Suitable for water and electric systems, especially in cold regions

(2) Building Insulation

- Roof insulation for steel structures

- Wall insulation for summer/winter thermal control

- Ceiling insulation for offices, hotels, and residences

(3) Pipe Insulation

- HVAC, heating, industrial pipelines

- Reduces energy loss and protects environment

(4) Solar Energy

- Flat plate solar collector backboard

- Photovoltaic panel insulation

(5) Other Special Scenarios

- Cold storage walls for moisture barrier

- Greenhouse insulation for plant growth

- Vehicle insulation for RVs or cold-chain trucks

8. Buying Guide: Practical Tips and Precautions

(1) Identify Needs

- Long-term residential: Mirror or PET aluminum

- Temporary structures or budget: Paper-based foil

- Uneven or humid floors: Nonwoven or bubble pad foil

- High energy-saving demand: Reflectivity ≥95%, strong tensile strength

(2) Avoid Common Mistakes

- Choosing only by price

- Assuming thicker foil is better

- Ignoring certification reports

- Confusing aluminum foil with vacuum-coated foil

(3) Choose Reputable Suppliers

- Check manufacturing capability, equipment, and quality control

- Request samples and test performance

(4) Consider After-Sales Service

- Technical support, installation guidance, replacement for defects

9. Conclusion: Core Value and Future Trends

Underfloor heating reflective foil provides “energy-saving + practical” value: reduces heat loss, increases efficiency, and offers easy installation, durability, and wide applications. Future trends include:

- High Performance: Improved reflectivity, tensile strength, and corrosion resistance

- Multi-Functionality: Integration of antibacterial, fire-resistant, and soundproof properties

- Environmental Friendliness: Eco-friendly materials and low-VOC adhesives

Choosing high-quality reflective foil and proper installation enhances heating efficiency, reduces energy consumption, and prolongs the lifespan of underfloor systems and insulation layers. This comprehensive guide helps avoid pitfalls, select the right product, and achieve high-efficiency heating and insulation.

Tradsark New Materials – Your Trusted Partner for High-Quality Reflective Films

As a leading manufacturer and exporter in the metallized film industry, Tradsark New Materials (Weifang) Co., Ltd. stands out for its commitment to quality, innovation, and customer satisfaction. With advanced production lines and strict quality control systems, Tradsark ensures that every floor heating reflective film meets international standards for reflectivity, durability, and safety.

Key Advantages of Tradsark:

- High-Quality Products: Using premium aluminum foil, BOPET, BOPP, CPP, and PE materials, Tradsark produces reflective films with superior infrared reflection, mechanical strength, and long-term stability.

- Comprehensive Certifications: Our products comply with CE Food Grade Certification, ISO9001, ISO14001, and ISO45001, ensuring safety and reliability for diverse applications.

- Advanced Production Technology: State-of-the-art high-temperature composite lines and online inspection systems guarantee consistent product performance, from uniform thickness to high peel strength and reflectivity.

- Customized Solutions: Tradsark offers flexible options in film size, thickness, and material type, tailored to meet the specific needs of residential, commercial, industrial, and agricultural projects.

- Global Reach & Support: With a strong international presence, professional logistics, and dedicated after-sales service, Tradsark ensures timely delivery and technical support for customers worldwide.

Choosing Tradsark reflective films not only enhances underfloor heating efficiency and energy savings but also provides peace of mind with reliable quality and consistent performance. Whether for floor heating systems, building insulation, solar energy applications, or industrial pipe insulation, Tradsark is the trusted partner for achieving superior thermal management and energy efficiency.