Energy Saving Aluminum Floor Heating Reflective Film: Enhance Comfort and Reduce Energy Costs

Introduction: The Rising Need for Energy Efficiency

As global energy costs continue to rise and environmental awareness increases, energy efficiency has become a top priority in building construction. Homeowners, commercial developers, and industrial facilities are constantly seeking solutions to reduce energy consumption without compromising comfort. Among the most effective strategies is the use of energy-saving aluminum floor heating reflective film. This innovative product ensures that underfloor heating systems operate efficiently, delivering heat directly where it is needed while minimizing energy waste.

Reflective films are not just a supplementary product—they are a critical component in modern building design, especially in regions with harsh winters or fluctuating temperatures. By reflecting radiant heat back into the living space, these films can reduce heat loss, accelerate floor warm-up, and lower energy bills.

Understanding Aluminum Floor Heating Reflective Film

What Is Reflective Film?

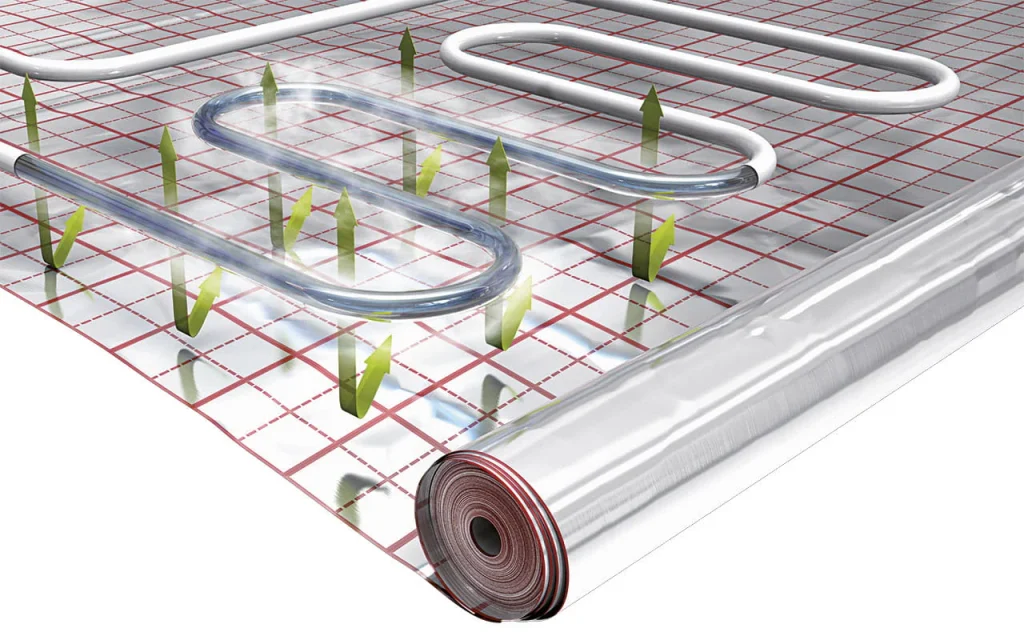

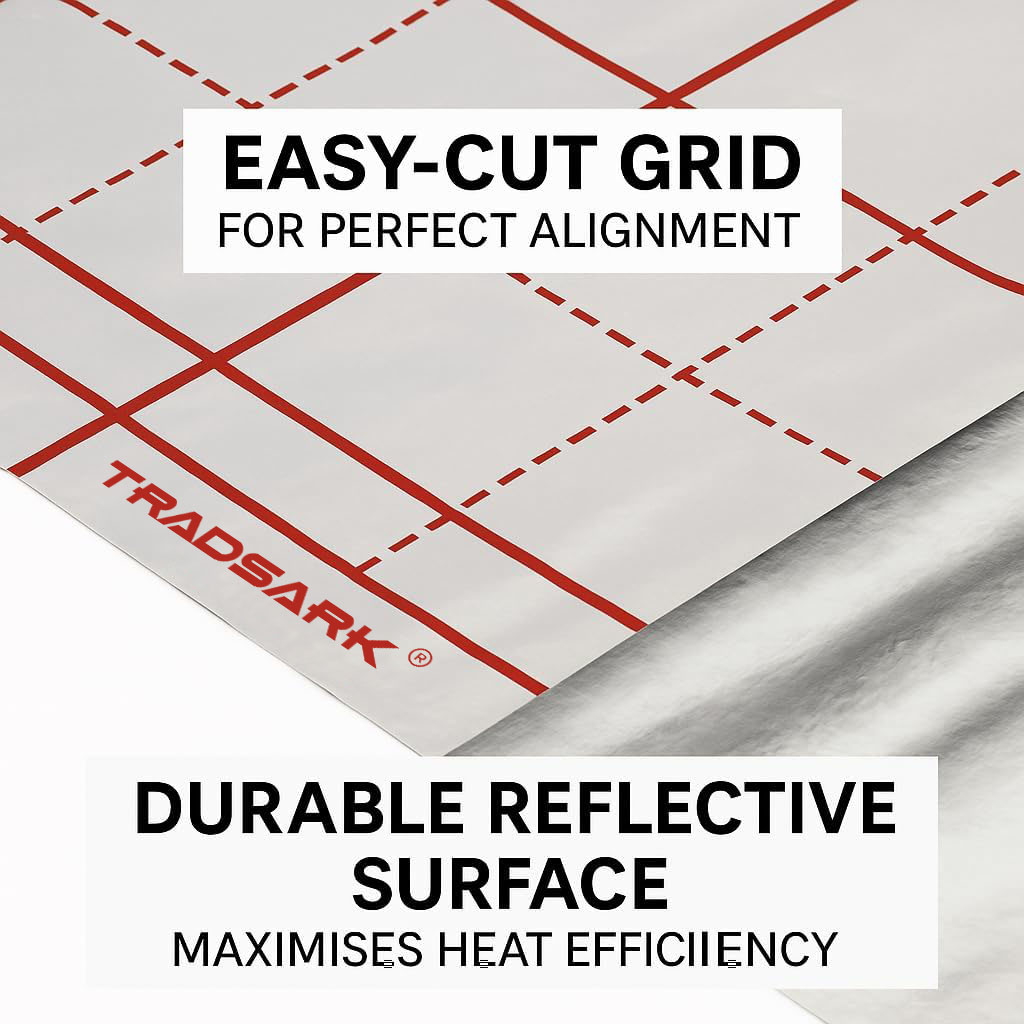

Aluminum floor heating reflective film is a specialized insulation material designed to enhance the performance of underfloor heating systems. It typically consists of a thin aluminum layer laminated between protective PET layers, combining durability, flexibility, and high reflectivity. The reflective layer redirects heat that would otherwise escape through the subfloor, improving energy efficiency.

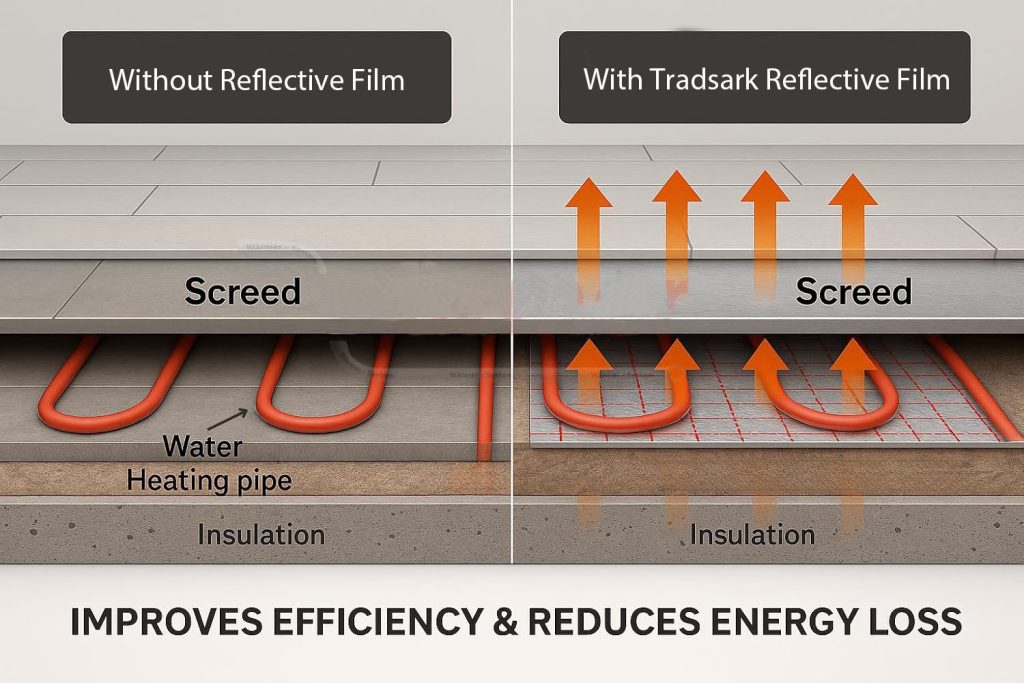

How It Works

Reflective films function based on the principle of thermal radiation reflection. When heat from underfloor pipes or panels rises, the reflective surface directs it upward into the room rather than allowing it to dissipate into the floor structure. This ensures that the warmth reaches the intended area efficiently, providing consistent indoor temperatures and reducing energy consumption.

Key Advantages of Aluminum Reflective Films

- High Reflectivity (≥97%) – Maximizes heat reflection, ensuring that underfloor heating systems deliver optimal warmth.

- Durable Multi-Layer Construction – Two protective PET layers encase the aluminum core, preventing tears and damage.

- Moisture and Corrosion Resistance – Maintains performance in humid or alkaline environments.

- Long Service Life – Designed to last over 50 years, matching the lifespan of the building.

- Easy Installation – Films come with meter marks for precise cutting and placement, compatible with various flooring types.

- Eco-Friendly and Sustainable – Non-toxic, recyclable materials reduce environmental impact.

- Cost-Effective – Reduces energy consumption and long-term heating expenses.

Materials and Technical Specifications

| Property | Specification |

|---|---|

| Material | Aluminum foil + PET protective layers |

| Reflectivity | ≥97–98% |

| Thickness | 0.03–0.06 mm |

| Width | 1000 mm (customizable) |

| Length | 100 m per roll (customizable) |

| Operating Temperature | -20°C to 60°C (standard) / 60°C to 90°C (high temperature resistant) |

| Lifespan | 50+ years |

| Applications | Underfloor heating, pipe insulation, energy-efficient building insulation |

This high-quality composite structure ensures that the reflective film is durable, flexible, and resistant to wear, even in heavy-use or industrial applications.

Applications Across Different Markets

Aluminum reflective films are increasingly adopted across global markets due to their versatility and energy-saving potential.

Residential Use

In modern homes, reflective films are installed beneath laminate, engineered wood, vinyl, or carpeted floors. Homeowners benefit from faster heat-up times, lower energy bills, and uniform warmth across rooms. The films also prevent heat loss through subfloors in cold climates, making them essential for northern regions in China, Eastern Europe, and Central Asia.

Commercial Buildings

Hotels, offices, and retail spaces use reflective films to enhance heating efficiency without increasing operational costs. In these large spaces, small improvements in thermal efficiency translate into significant energy savings.

Industrial and Warehouse Applications

Factories and warehouses equipped with underfloor heating systems require durable and long-lasting insulation solutions. Aluminum reflective films reduce heat loss, improve workplace comfort, and contribute to overall energy management strategies.

Sustainable Construction Projects

Modern construction increasingly focuses on green building standards such as LEED and BREEAM. Installing reflective films contributes to certification criteria by reducing energy consumption, minimizing carbon footprint, and promoting sustainable building practices.

How Reflective Films Improve Underfloor Heating Efficiency

Traditional underfloor heating systems often lose heat through the subfloor, reducing the system’s overall effectiveness. Reflective films address this issue by:

- Reducing Heat Loss – Up to 97% of radiant heat is reflected into the living area.

- Optimizing Temperature Distribution – Prevents cold spots and ensures uniform warmth.

- Enhancing Comfort – Floors heat more quickly, and indoor temperature stabilizes faster.

- Lowering Energy Bills – Reduced heat loss translates into lower electricity or gas usage.

Installation Best Practices

Proper installation is key to maximizing the benefits of reflective films:

- Clean and Level Subfloor – Remove debris, dust, and uneven areas.

- Correct Orientation – Ensure reflective side faces the heat source.

- Seam Overlap – Slight overlap or adhesive tape on edges prevents heat leakage.

- Avoid Damage – Do not puncture or fold excessively.

- Compatible Flooring – Works with laminate, vinyl, engineered wood, or carpeted floors.

Following these steps ensures long-term energy efficiency and optimal performance.

Comparative Analysis: Reflective Film vs Traditional Insulation

| Feature | Traditional Insulation | Aluminum Reflective Film |

|---|---|---|

| Reflectivity | 70–80% | 97–98% |

| Lifespan | 3–5 years | 50+ years |

| Moisture Resistance | Limited | Excellent |

| Durability | Low | High |

| Installation Complexity | High | Easy |

| Environmental Impact | Non-recyclable | Recyclable and eco-friendly |

Reflective films clearly outperform traditional insulation in efficiency, durability, and sustainability.

Technical Production: How Tradsark Creates High-Quality Reflective Films

Tradsark uses advanced vacuum metallization technology to deposit a uniform aluminum layer onto PET film. The film is then laminated on both sides with protective PET layers, resulting in a strong, flexible, and highly reflective product.

Quality Assurance Includes:

- Reflectivity testing

- Heat conductivity measurement

- Tensile strength evaluation

- Alkaline resistance tests

- Fire retardancy certification

All production processes adhere to ISO9001, ISO14001, and CE standards, ensuring reliability for domestic and international markets.

Global Export and Market Presence

Tradsark reflective films are exported to multiple regions:

- China – Residential and commercial buildings across northern and southern provinces.

- Central Asia – Kazakhstan, Uzbekistan, Kyrgyzstan, Turkmenistan, Tajikistan.

- Eastern Europe – Poland, Czech Republic, Romania, Hungary.

- Western Europe – Germany, France, UK, Italy, Spain.

Tradsark is a trusted supplier for European Amazon sellers, providing source-level products for resale and OEM solutions. In Central Asia, the company supports both construction and HVAC distributors with custom specifications and reliable logistics.

OEM Services and Customization

Tradsark offers full OEM support, including:

- Custom roll widths and lengths

- Private label branding

- Custom packaging for export

- Bulk supply for industrial and commercial projects

This flexibility allows clients to adapt reflective films to their specific project needs while maintaining consistent quality.

Case Studies and Success Stories

- Kazakhstan Residential Project – 50,000 m² installed, energy consumption reduced by 27%.

- Poland Amazon OEM Supply – Branded reflective films supplied to multiple European countries.

- Germany Eco-Building Program – Sustainable residential projects benefited from uniform floor heating and reduced energy bills.

- China Northern Region – Retrofit projects demonstrated improved indoor comfort and faster heating times.

Common Challenges and Solutions

Challenge 1: Heat loss through subfloor

- Solution: Use high-reflectivity films (≥97%) with proper installation.

Challenge 2: Moisture penetration

- Solution: Multi-layer PET protection resists damp and alkaline conditions.

Challenge 3: Incorrect installation

- Solution: Ensure reflective side faces the heat source, overlap seams, and avoid punctures.

Challenge 4: Floor compatibility

- Solution: Verify flooring type before installation to ensure efficient heat reflection.

Environmental and Economic Benefits

- Reduced Energy Consumption – Lower heating costs and less carbon footprint.

- Durable and Long-Lasting – Reduces replacement frequency and material waste.

- Eco-Friendly Materials – Recyclable PET and aluminum minimize environmental impact.

- Cost-Effective Investment – Quick ROI through energy savings and reduced maintenance costs.

Conclusion

Energy-saving aluminum floor heating reflective films are essential for modern, energy-efficient buildings. Tradsark New Materials (Weifang) Co., Ltd. provides high-quality, durable, and sustainable reflective films suitable for residential, commercial, and industrial applications across China, Central Asia, Eastern Europe, and Western Europe.

With proper installation, trusted supplier support, and a clear understanding of energy efficiency principles, building owners and developers can achieve optimal thermal comfort, reduce energy costs, and support sustainable construction practices.

Choosing Tradsark reflective films ensures high performance, long-term reliability, and global compliance, making it the preferred choice for projects seeking efficiency, durability, and environmental responsibility.