The PE stretch film industry in China is entering a period of accelerated growth driven by e-commerce logistics, manufacturing, export trade, and the rising demand for high-performance packaging materials. From 2025 to 2030, the market is expected to expand steadily as sustainability policies and advanced production technologies reshape the entire value chain.

This article provides an in-depth analysis of China’s PE stretch film market, including industry size, policy impact, product trends, technological innovations, and future opportunities—along with insights into how companies like Tradsark New Materials (Weifang) Co., Ltd. are shaping the next stage of industry development.

1. What Is PE Stretch Film?

1.1 Definition

PE stretch film is a flexible packaging material made primarily from LLDPE using cast or blown film technology. It is widely used for:

- Pallet wrapping and cargo protection

- E-commerce packaging

- Industrial product bundling

- Dust-proof and moisture protection

- Logistics transportation stabilization

It features high transparency, excellent stretchability, puncture resistance, and strong load-holding performance.

2. China’s Market Size Forecast (2025–2030)

2.1 Strong Growth Driven by Multiple Sectors

The Chinese PE stretch film market reached approximately USD 4.4 billion in 2024. Growth is expected to continue due to:

- Double-digit annual increase in e-commerce shipments

- Expanding demand from lithium battery, solar panel, and new energy sectors

- Steady recovery in export industries

- Higher packaging safety requirements in global trade

By 2030, the market is projected to exceed USD 7 billion, maintaining strong competitiveness within Asia-Pacific.

3. Policy and Regulatory Environment in China

3.1 Updated Plastic Restriction Policies

China’s upgraded plastic restriction and recycling policies require:

- Thinner, stronger, lightweight packaging

- Higher recyclability and reduced single-use plastics

- Encouragement of PCR (post-consumer recycled) content

3.2 Carbon Neutrality Accelerates Transformation

The “Dual Carbon Goals” (carbon peak & carbon neutrality) push manufacturers to:

- Adopt energy-efficient production lines

- Implement carbon footprint management

- Develop eco-friendly stretch film solutions

Regulations will drive industry consolidation, benefiting companies with advanced equipment and environmental compliance.

4. Technology Trends in China’s PE Stretch Film Industry

4.1 High-Performance Film Development

Future production capacity will focus on:

- Ultra-thin high stretch films (down to 10–12 μm)

- Nano-reinforced stretch films

- Machine-grade fully automatic wrap films

- High puncture-resistance packaging solutions

4.2 Sustainable Materials Are Rising

Eco-friendly packaging is becoming essential. Key directions include:

- PCR recycled stretch film

- Bio-based PE stretch film

- Degradable material combinations (PLA, PBAT)

- Low-carbon raw materials

5. Major Application Fields in China

5.1 E-Commerce and Logistics

China’s express parcel volume exceeds 130 billion packages annually, making it the fastest-growing stretch film consumption sector.

5.2 New Energy Manufacturing

Demand comes from:

- Lithium battery module packaging

- Solar panel transportation

- EV components logistics

Stretch film serves as a key material for stabilizing high-value components.

5.3 Export Trade

International shipments of home appliances, food, machinery, and consumer goods rely heavily on pallet wrapping, supporting continuous demand for industrial-grade stretch film.

6. Industry Opportunities (2025–2030)

- Automated packaging and machine-grade stretch film

- Lightweight, ultra-thin high-strength solutions

- Large overseas OEM/ODM orders

- Green and recyclable packaging materials

- Smart logistics system integration

China’s manufacturers maintain competitive advantages in cost, technology scale, and export supply stability.

7. Industry Challenges

- Fluctuation of LLDPE raw material prices

- Increasing environmental compliance requirements

- Industry overcapacity in low-end segments

- Customer demand shifting toward innovation and sustainability

Companies must upgrade products, strengthen brand capability, and focus on environmentally friendly solutions to stay competitive.

8. The Role of Tradsark in China‘s Stretch Film Industry

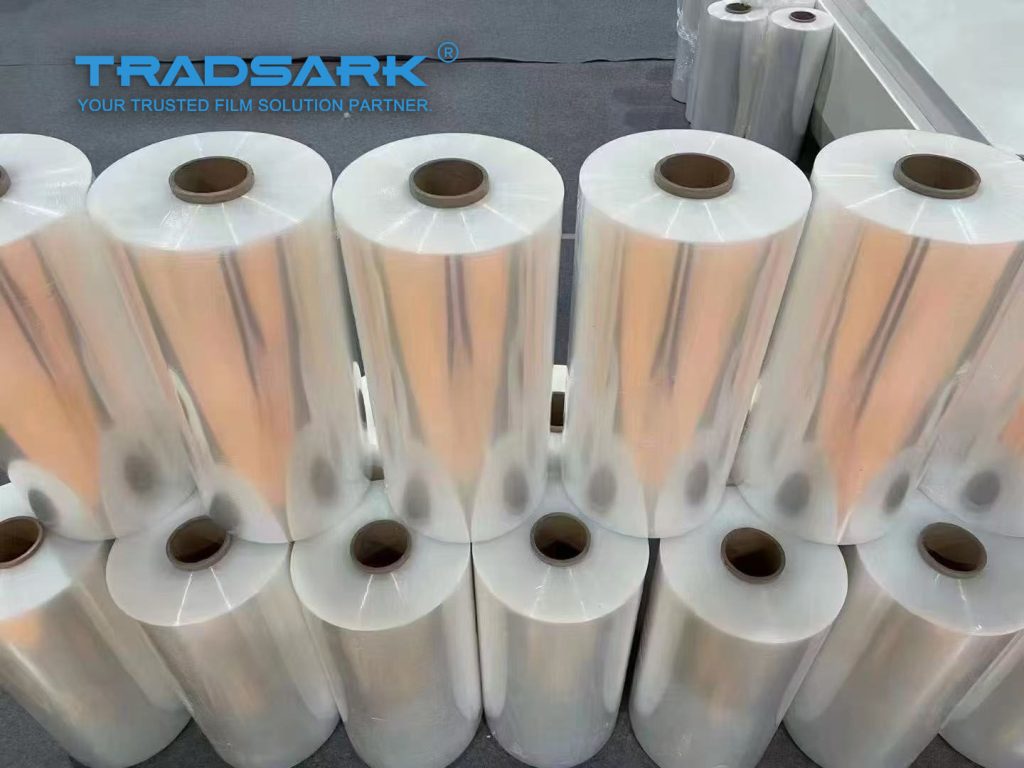

Tradsark New Materials (Weifang) Co., Ltd. is a leading manufacturer in China specializing in PE stretch film, BOPP, BOPET, CPP, metallized films, agricultural reflective films, and more.

8.1 Advanced Production Strength

- 12 modern production lines, including advanced Brückner equipment

- 6,300+ employees

- Strong capabilities in both transparent and metallized films

- CE, ISO9001, and other international certifications

8.2 Product Advantages

- High-strength, high-transparency stretch film

- Options for ultra-thin, eco-friendly, and PCR materials

- Stable quality suitable for export markets

- Strong R&D for sustainable packaging solutions

8.3 Serving Global Markets

Tradsark exports to Latin America, Europe, Southeast Asia, and the Middle East, providing stable delivery and OEM/ODM services for global packaging brands.

9. Market Outlook and Future Trends

From 2025 to 2030, China’s PE stretch film industry will move toward:

- Stronger, thinner, and more sustainable films

- Large-scale adoption of PCR recycled content

- Automation and intelligent packaging systems

- Growing international market penetration

- Integration of digital supply chain solutions

Companies equipped with advanced technology, sustainability capability, and large-scale manufacturing—such as Tradsark—will lead the next stage of industry growth.

10. Conclusion

The PE stretch film market in China is set for vigorous expansion through 2030. Driven by e-commerce, manufacturing, and global trade, along with sustainability demands, the industry is experiencing both significant opportunities and structural upgrades.

Manufacturers who invest in high-performance films, eco-friendly materials, and large-scale automated production will secure long-term competitiveness.

Tradsark is well-positioned to take advantage of this transformation, offering high-quality packaging films for global clients seeking reliability, innovation, and sustainable manufacturing.