Introduction

Polyester films, particularly PET (Polyethylene Terephthalate) films, are widely used in various industries due to their excellent mechanical properties, chemical resistance, and versatility. Among these, Aluminized Polyester Film and Metalized Polyester Film have gained significant attention because of their reflective surfaces, barrier properties, and decorative appeal. Manufacturers and suppliers worldwide, especially in China, offer these films for applications ranging from food packaging and insulation to decorative and industrial uses. Understanding the differences between aluminized and metalized films is crucial for buyers to make informed decisions regarding quality, performance, and cost-efficiency.

This guide aims to provide an in-depth comparison of aluminized and metalized polyester films, discuss their respective manufacturing processes, properties, applications, and supply chain considerations, and help procurement managers, manufacturers, and end-users select the right product and supplier.

What is Aluminized Polyester Film?

Aluminized Polyester Film is a type of PET film coated with a thin layer of aluminum, typically applied through vacuum deposition. This process creates a reflective metallic surface with excellent thermal and barrier properties.

Manufacturing Process

- Base Film Production: A high-quality PET film is extruded or cast to form a smooth, uniform base.

- Surface Preparation: The PET surface is treated to improve adhesion of the aluminum layer.

- Vacuum Aluminum Coating: Aluminum is evaporated in a vacuum chamber and deposited evenly onto the PET film.

- Winding and Quality Control: The finished aluminized film is wound into rolls and inspected for uniformity, thickness, and reflectivity.

Properties

- High Reflectivity: The aluminum layer provides mirror-like reflection, ideal for heat insulation and decorative purposes.

- Excellent Heat Resistance: Can withstand high temperatures without deforming, making it suitable for industrial applications.

- Good Moisture and Gas Barrier: Prevents oxygen, moisture, and light from penetrating, protecting food and sensitive products.

- Durability: Resistant to puncture and abrasion.

- Metallic Luster: Provides premium aesthetic appeal for decorative packaging.

Applications

- Food Packaging: Snacks, coffee, and confectionery packaging requiring moisture and light barrier properties.

- Insulation Materials: Underfloor heating reflective films, thermal insulation for HVAC systems.

- Decorative Uses: Metallic wrapping, labels, and laminates for premium products.

- Industrial Applications: Reflective sheets for electronics and automotive industries.

What is Metalized Polyester Film?

Metalized Polyester Film is similar to aluminized film but refers to PET films coated with a thin layer of metal, which can be aluminum, silver, or other metals. Unlike aluminized films, the metal layer in metalized PET films is generally thinner, primarily for decorative and barrier functions rather than structural support.

Manufacturing Process

- Base PET Film Production: High-quality PET film is produced with smooth surfaces.

- Surface Treatment: Enhances metal adhesion.

- Metal Deposition: Through vacuum metallization or sputtering, a thin metal layer is applied. Aluminum is the most common, but other metals may be used for specialized applications.

- Finishing and Quality Inspection: Rolls are checked for uniformity, optical clarity, and barrier properties.

Properties

- High Gloss and Metallic Finish: Provides aesthetic appeal for packaging and decorative applications.

- Moisture and Light Barrier: Offers moderate protection, though generally less robust than aluminized films.

- Flexible and Lightweight: Easier to handle and process into pouches, wraps, and laminates.

- Cost-Effective: Thinner metal layers reduce material cost.

Applications

- Food and Pharmaceutical Packaging: Barrier films for snacks, medicines, and confectionery.

- Decorative Packaging: Labels, wrappers, gift packaging, and laminates.

- Industrial Applications: Reflective layers for electronics, insulation laminates, and signage.

- Advertising and Printing: Offers glossy metallic effects on printed films.

Aluminized vs Metalized Polyester Film: Key Differences

Although both films involve metallic coatings on PET, several distinctions affect performance, application, and cost.

| Feature | Aluminized Polyester Film | Metalized Polyester Film |

|---|---|---|

| Metal Layer | Aluminum only, thicker | Aluminum or other metals, thinner |

| Reflectivity | High, mirror-like | Moderate to high |

| Thermal Resistance | Strong, withstands higher temperatures | Moderate |

| Barrier Properties | Excellent against moisture, light, and gases | Good, but slightly less effective |

| Durability | High puncture and abrasion resistance | Moderate |

| Applications | Industrial insulation, food packaging, decorative laminates | Food packaging, decorative, lightweight industrial use |

| Cost | Higher | Lower |

| Suppliers | Typically specialized PET film manufacturers | Widely available from general PET film suppliers |

Core takeaway: If the primary need is high-performance barrier and thermal insulation, aluminized PET is preferable. For decorative packaging or cost-sensitive applications, metalized PET is sufficient.

How to Choose a Supplier for Aluminized and Metalized Polyester Films

1. Country of Supply: China Advantage

China is the world’s largest producer of PET films, including aluminized and metalized varieties. Advantages include:

- Competitive Pricing: Lower production costs without compromising quality.

- Large Production Capacity: Ability to handle bulk orders.

- Variety of Product Options: Multiple thicknesses, metal coatings, and finishes.

- Experience with Export: Many suppliers have ISO, CE, and FDA certifications for international markets.

2. Certifications and Quality Assurance

- ISO 9001: Quality management systems.

- ISO 14001: Environmental management for sustainable production.

- ISO 45001: Occupational health and safety.

- Food-Grade Certifications: For films used in edible packaging.

3. Minimum Order Quantity (MOQ) and Lead Time

- MOQs vary depending on thickness, width, and coating type.

- Standard lead time is 2–6 weeks, depending on production schedules and shipping.

4. Supplier Evaluation Tips

- Request sample rolls for testing barrier, reflectivity, and heat resistance.

- Check existing client references to assess reliability.

- Evaluate after-sales service, including customization options.

5. Key Chinese Manufacturers to Consider

While there are many, some reputable companies include:

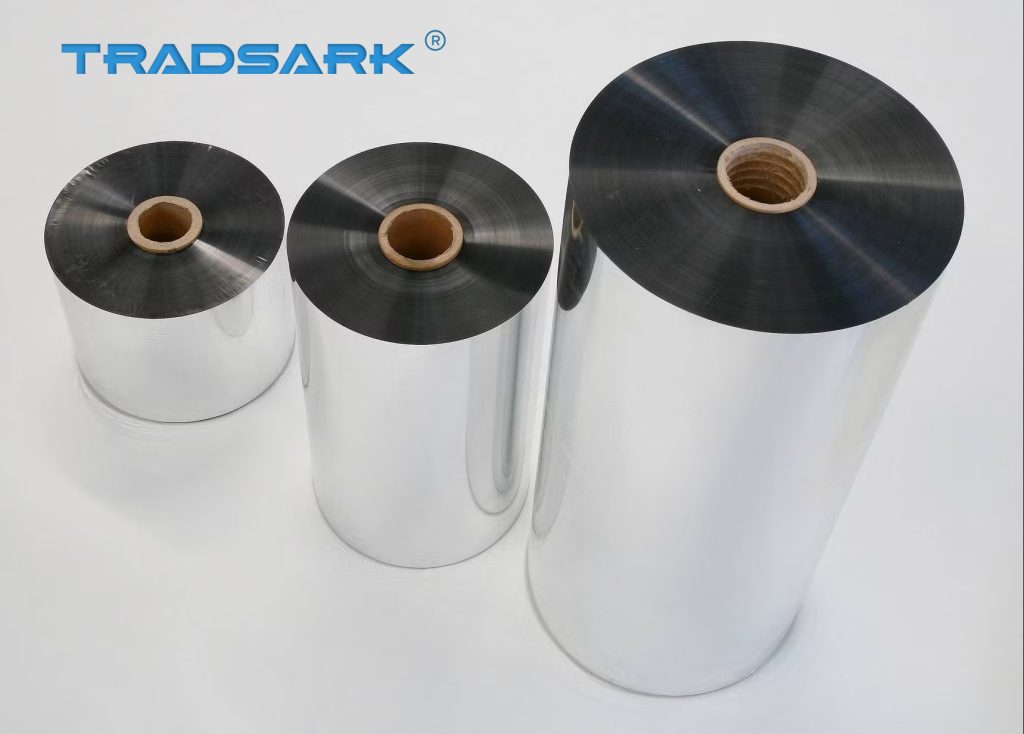

- Tradsark New Materials (Weifang) Co., Ltd. – Offers BOPP, CPP, PET, and aluminized films with food-grade certifications.

- Zhejiang Changyu New Materials Co., Ltd. – Specializes in metallized PET and decorative films.

- Guangdong Cailong New Material Co., Ltd. – High-quality aluminized films for industrial and packaging applications.

These suppliers cater to international markets including North America, Europe, and Asia.

Applications in Detail

1. Food Packaging

- Aluminized PET: Ideal for high-barrier packaging like coffee bags, snack pouches, and instant noodles.

- Metalized PET: Used for candy wrappers, chocolate foils, and decorative packaging.

2. Industrial Insulation

- Aluminized PET: Heat reflective films for HVAC systems, underfloor heating reflective membranes, and thermal insulation panels.

- Metalized PET: Reflective laminates for electronics insulation, signage, and protective films.

3. Decorative Uses

- Both films are used for gift packaging, labels, and laminates.

- Metalized PET is more cost-effective for large-scale decorative applications.

- Aluminized PET provides a premium metallic finish with higher reflectivity.

How to Choose Between Aluminized and Metalized PET Film

Step 1: Identify Application Requirements

- Barrier strength, heat resistance, and durability → Aluminized PET

- Decorative appeal, lightweight, cost-sensitive → Metalized PET

Step 2: Consider Production Costs

- Aluminized PET is generally more expensive due to thicker metal layer and functional properties.

- Metalized PET is cheaper but may not meet high-barrier industrial requirements.

Step 3: Supplier Capability

- Check if suppliers can provide custom thickness, widths, and coatings.

- Evaluate lead time, certifications, and export experience.

Step 4: Test Samples

- Always test small batches for performance in intended applications.

Conclusion

Both Aluminized and Metalized Polyester Films play a crucial role in packaging, insulation, and decorative industries. Understanding their differences helps businesses make informed purchasing decisions.

- Choose Aluminized PET for industrial, high-barrier, or heat-resistant applications.

- Choose Metalized PET for decorative, lightweight, and cost-effective packaging.

When sourcing, consider reputable Chinese manufacturers such as Tradsark New Materials (Weifang) Co., Ltd., Zhejiang Changyu, and Guangdong Cailong, which provide quality products with certifications, competitive prices, and reliable export services. Proper evaluation, testing, and supplier selection ensure optimal performance and long-term satisfaction.

By understanding the distinctions and sourcing from credible suppliers, businesses can maximize product quality, reduce costs, and meet the diverse demands of global markets.