Chapter 1:What Is Aluminized Polyester Film (Met PET)?

The High-Performance Hybrid for Advanced Barrier & Thermal Solutions

Aluminized Polyester Film, commonly known in the industry as Met PET, is a high-performance material produced by vacuum-depositing a microscopic layer of high-purity aluminum onto the surface of a biaxially-oriented polyethylene terephthalate (BOPET) substrate.

This process creates a “hybrid” material that retains the mechanical strength, clarity, and heat resistance of polyester while gaining the superior light, oxygen, and moisture barrier properties of aluminum foil—at a significant cost and weight advantage.

Chapter 2:Key Applications of Aluminized PET Film

Engineering Solutions Across High-Stakes Industries

The unique combination of polyester’s mechanical strength and the thermal/barrier properties of aluminum makes Aluminized PET film a critical material in global supply chains. Below are the primary sectors where Met PET provides a competitive edge.

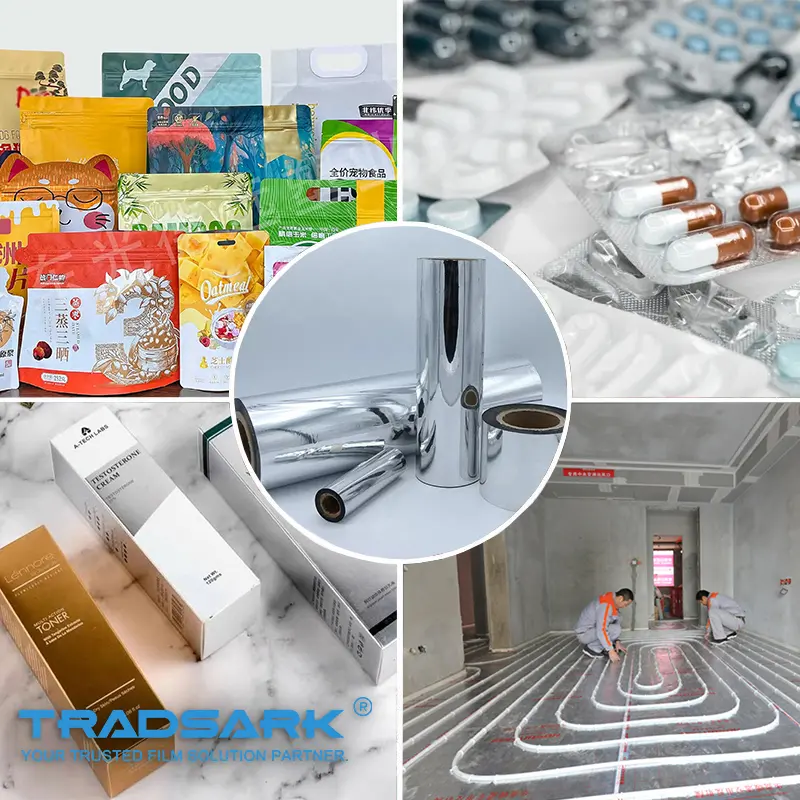

1. Advanced Flexible Packaging

In the food and pharmaceutical sectors, Met PET is the preferred substrate for high-speed “form-fill-seal” (FFS) lines.

- Extended Shelf Life: Its high Optical Density (OD) provides a superior barrier against oxygen and moisture, keeping snacks crisp and powdered medicines dry.

- UV Protection: The metallic layer acts as a total light shield, preventing the oxidation of oils and fats in products like coffee, nuts, and dairy-based powders.

- Aesthetic Appeal: It provides a premium, mirror-like finish that enhances “shelf presence” for luxury consumer goods.

2. High-Performance Thermal Insulation

Met PET is a cornerstone of the modern construction and aerospace industries due to its ability to manage heat radiation.

- Radiant Barriers: In green building projects, it is used in attics and wall cavities to reflect up to 98% of radiant heat, significantly reducing HVAC energy consumption.

- Cold Chain Logistics: Used as a liner for thermal shipping bags and container blankets to maintain the integrity of temperature-sensitive pharmaceuticals and perishables.

- Space & Emergency Blankets: Its lightweight nature and high heat retention make it life-saving equipment for outdoor survival and satellite insulation.

3. Electronics & Electrical Shielding

As devices become smaller and more sensitive, Met PET’s conductive properties become essential.

- EMI/RFI Shielding: It is used as a wrap for telecommunication cables to prevent electromagnetic interference (EMI) and radio frequency interference (RFI).

- Capacitors: In the electrical industry, ultra-thin metallized PET serves as the dielectric medium in film capacitors, valued for its high dielectric constant and self-healing properties.

- Flexible Circuitry: Acts as a lightweight, flexible base for printed electronic components.

4. Technical Graphics & Decorative Media

Beyond performance, the material is highly valued for its visual and tactile properties.

- Self-Adhesive Labels: Used for high-end “silver” or “gold” labels on electronics, cosmetics, and automotive parts that require durability and weather resistance.

- Holographic Substrates: Met PET is the base material for holographic security foils used in ID cards, credit cards, and brand protection packaging.

- Metallic Yarn: Slit into micro-threads, it is woven into textiles to create the “Lurex” effect in fashion and upholstery.

B2B Pro-Tip: Matching Application to Grade

When selecting an Aluminized PET film, the application dictates the specification:

| Industry | Primary Requirement | Recommended Spec |

| Snack Packaging | Moisture Barrier | 12μm / OD 2.2 – 2.5 |

| Roofing Insulation | Thermal Reflection | 25μm – 50μm / OD 3.0+ |

| Cable Wrapping | Conductivity/Shielding | 12μm – 23μm / High Metal Adhesion |

| Balloons/Graphics | Gloss & Aesthetics | 10μm – 12μm / High Dyne Level |

Chapter 3:Specialized Laminate Structures by Tradsark

Precision-Engineered Multi-Layer Solutions for Global Industries

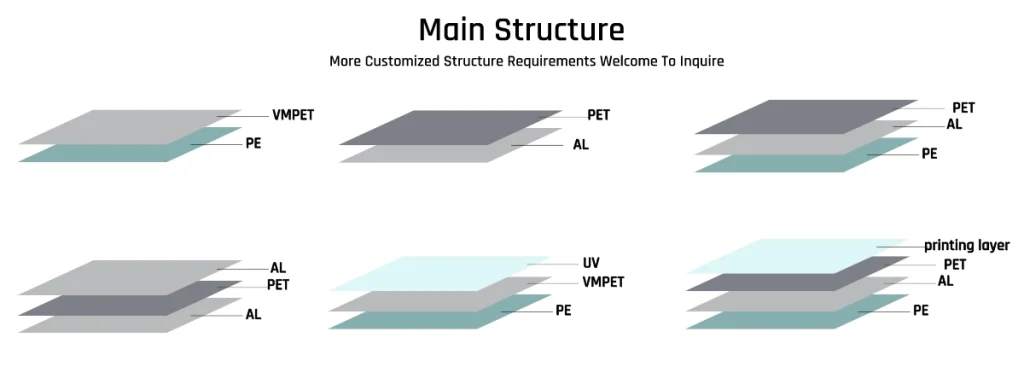

At Tradsark, we provide more than just base film. We offer six specialized multi-layer structures designed to solve the most demanding technical challenges in barrier protection, structural integrity, and cost-efficiency. By combining BOPET, Aluminum Foil (AL), Metallized Film (VMPET), and Polyethylene (PE), Tradsark creates high-performance laminates for diverse global markets.

The Tradsark Core Product Portfolio

1. VMPET + PE (Metallized Polyester / Polyethylene)

- Characteristics: A cost-effective structure by Tradsark that combines the high barrier of metallized film with the excellent heat-sealability of PE.

- Best For: General snack foods, biscuits, and daily consumer goods packaging.

2. PET + AL (Polyester / Aluminum Foil)

- Characteristics: This Tradsark structure utilizes Pure Aluminum Foil, providing a near-100% barrier against moisture, oxygen, and UV light. It is much more robust than standard metallized film.

- Best For: High-end tea packaging, precision electronic components, and industrial moisture-proof liners.

3. PET + AL + PE (Polyester / Aluminum Foil / Polyethylene)

- Characteristics: The classic “Triplex” structure. Tradsark ensures PET provides rigidity, AL offers a total barrier, and PE ensures a leak-proof thermal seal.

- Best For: Pharmaceutical powders, vacuum-packed coffee, and high-stakes liquid packaging.

4. AL + PET + AL (Aluminum Foil / Polyester / Aluminum Foil)

- Characteristics: A symmetrical metallic sandwich structure engineered by Tradsark for extreme mechanical strength and dual-sided thermal reflectivity.

- Best For: High-performance building insulation, aerospace thermal blankets, and heavy-duty EMI shielding.

5. UV + VMPET + PE (UV-Resistant / Metallized PET / Polyethylene)

- Characteristics: Specifically engineered by Tradsark with a UV-protection layer to prevent contents from degrading due to sunlight while protecting the metal layer.

- Best For: Cosmetic sachets, outdoor chemical packaging, and light-sensitive products.

6. PRINTING LAYER + PET + AL + PE

- Characteristics: A complete, ready-to-convert structure. Tradsark optimizes the surface for high-definition graphics, backed by the ultimate protection of an aluminum foil core.

- Best For: Premium branded food pouches and medical-grade packaging.

Tradsark Procurement Selection Matrix

| Structure Type | Barrier Level | Key Advantage | Typical Application |

| 1. VMPET + PE | High | Most Cost-Effective | Retail Snacks / General Goods |

| 2. PET + AL | Extreme | Total Light/Moisture Block | Industrial Intermediates |

| 3. PET + AL + PE | Ultimate | Most Balanced Performance | Pharmaceuticals / Premium Coffee |

| 4. AL + PET + AL | Ultimate | High Thermal Reflectivity | Construction / Aerospace |

| 5. UV + VMPET + PE | High | Solar & UV Protection | Cosmetics / Outdoor Products |

| 6. PRINT + PET + AL + PE | Ultimate | One-Stop Branded Solution | Retail Brand Packaging |

Chapter 4: Understanding Aluminum Layer Quality

Ensuring Barrier Integrity and Durability with Tradsark

In the metallized film industry, not all “silver” surfaces are created equal. The quality of the aluminum layer is the single most important factor determining the shelf life of your product and its performance during lamination. At Tradsark, we utilize advanced vacuum deposition technology and rigorous testing to ensure every roll meets international standards.

1. Optical Density (OD): The Measure of Thickness

Optical Density refers to the thickness of the aluminum layer deposited on the PET film. It is measured by the amount of light that can pass through the film.

- Why it matters: A higher OD provides a denser barrier against oxygen, moisture, and light.

- The Tradsark Standard: We offer precise OD control ranging from 1.8 to 3.5. For high-barrier applications like coffee or pharmaceuticals, Tradsark recommends an OD of 2.8+ to ensure maximum product freshness.

2. Metal Adhesion: The “Tape Test”

A common failure in low-quality films is “metal transfer,” where the aluminum layer peels away from the PET base. This leads to delamination of the entire package.

- The Tradsark Solution: We perform standardized Tape Tests (ASTM D3359). Our chemical treatment and plasma-enhanced deposition ensure that the bond between the metal and the polyester is permanent.

- Benefit: This ensures that when you laminate Tradsark film with PE or other layers, the bond strength remains intact even under high heat or tension.

3. Surface Uniformity and Pinholes

Inconsistent aluminum deposition creates “weak spots” or pinholes that are invisible to the naked eye but allow oxygen to leak through.

- Tradsark’s Technology: Our high-speed vacuum coaters feature real-time monitoring systems that ensure the aluminum vapor is distributed with 100% uniformity across the entire web width. This eliminates hot spots and ensures consistent barrier properties from the start of the roll to the end.

4. Wetting Tension (Dyne Level)

For the aluminum layer to accept printing inks or adhesives, it must have high surface energy, measured in Dynes.

- The Tradsark Advantage: We ensure our metallized surfaces maintain a minimum of 42 dynes/cm. This high dyne level is critical for preventing ink-bleeding and ensuring that lamination glues spread evenly without “crawling.”

Quality Comparison at a Glance

| Feature | Standard Market Film | Tradsark Quality Film |

| Aluminum Uniformity | May show streaks or light spots | 100% Uniform Deposition |

| Metal Adhesion | Risk of peeling (Metal Transfer) | High Bond Strength (Passes Tape Test) |

| Pinhole Count | High (leads to shorter shelf life) | Ultra-low (optimized for long-term barrier) |

| Dyne Level | Often inconsistent or low | Guaranteed >42 Dynes for superior bonding |

Chapter 5: Surface Treatment and Lamination Compatibility

The Key to Flawless Bonding and Print Quality

A high-quality aluminum layer is only effective if it can be successfully integrated into a multi-layer structure. Surface treatment determines how well the film will bond with adhesives, inks, and other polymer layers like PE or CPP. Understanding the compatibility between the film surface and your conversion process is essential to avoiding costly delamination.

1. The Role of Surface Treatment

Raw polyester and freshly deposited aluminum have specific surface energies. To ensure industrial-grade bonding, the surface must be “activated.” There are three primary methods:

- Corona Treatment: The most common method. It uses high-voltage electrical discharge to increase the surface energy (Dyne level).

- Chemical Treatment (Primer): A microscopic chemical coating is applied during the film extrusion or before metallization. This provides a much more stable and aggressive bond than corona treatment.

- Plasma Treatment: Conducted inside the vacuum chamber, this advanced method cleans and micro-etches the surface at an atomic level, ensuring maximum metal adhesion.

2. Dyne Levels: The Universal Language of Adhesion

The effectiveness of surface treatment is measured in Dynes/cm. For successful lamination and printing, the surface tension of the film must be significantly higher than the surface tension of the liquid (ink or adhesive) being applied.

| Process Type | Required Dyne Level | Risk of Low Dyne |

| Solvent-Based Lamination | 38 – 40 Dynes | Poor bond strength; tunneling. |

| Solvent-Less Lamination | 40 – 42 Dynes | Bubbles; adhesive “crawling.” |

| Water-Based Printing | 42 – 44+ Dynes | Ink smearing; poor color density. |

| UV Curable Printing | 44 – 48 Dynes | Poor ink anchorage; peeling. |

3. Lamination Compatibility: Solving the “Delamination” Issue

When building a laminate (e.g., Structure #3: PET+AL+PE), the interface between the metal and the adhesive is the weakest link.

- Adhesive Selection: Not all glues work with aluminized surfaces. Using an aggressive solvent-based adhesive on a non-chemically treated film can sometimes “lift” the aluminum right off the PET base.

- The “Decay” Factor: Corona treatment is temporary. It naturally decays over time due to humidity and storage conditions. If you store film for too long, the Dyne level may drop below the required threshold, leading to lamination failure.

- Tradsark Professional Tip: For liquid packaging or high-humidity applications, always opt for Chemical Treated films. The chemical bond is permanent and does not decay like standard corona treatment.

Chapter 6: Food Safety Standards and Certifications

Global Compliance for Consumer Protection

When Aluminized Polyester Film is used in food packaging—whether as a snack bag liner or a coffee pouch—it becomes a Food Contact Material (FCM). Ensuring that the film does not migrate harmful substances into the food is a legal and ethical requirement. At the professional manufacturing level, adherence to international safety standards is non-negotiable.

1. Key Global Certifications

To compete in international markets, metallized films must meet the rigorous testing standards of major regulatory bodies:

- FDA Compliance (USA): The film must comply with FDA 21 CFR 177.1630, which regulates the safety of phthalate-free polymers and the indirect food additives used during the metallization and lamination process.

- EU Regulation (EC 10/2011): In Europe, films are tested for Overall Migration (OM) and Specific Migration Limits (SML). This ensures that the aluminum and polyester components do not migrate into fatty, acidic, or dry foods beyond safe levels.

- ISO 22000 & BRCGS: These certifications focus on the manufacturing environment. They guarantee that the film is produced in a clean, hazard-controlled facility to prevent physical or chemical contamination.

2. Migration Testing: Ensuring Purity

Food safety is verified through migration testing, simulating different storage conditions:

- Simulants: Testing the film against distilled water, acetic acid (for acidic foods), and ethanol (for fatty foods).

- Temperature Stress: Testing how the film reacts under high heat (e.g., sterilization or hot-filling) to ensure the laminate structure remains stable.

3. Material Purity: BPA & Phthalate Free

Modern consumers and brands demand “Clean Packaging.” Professional-grade Met PET must be:

- BPA-Free: Ensuring no Bisphenol A is used in the resin or coatings.

- Heavy Metal Free: The aluminum used in vacuum deposition must be high-purity (typically 99.9%), free from lead, cadmium, or mercury contamination.

4. Traceability: The Batch Record

A critical component of food safety is the ability to trace a product back to its raw materials. Professional suppliers provide a Certificate of Analysis (COA) with every shipment, linking the roll back to the specific batch of resin and aluminum wire used.

Chapter 7: How to Select a Reliable Aluminized Film Supplier

A Strategic Checklist for B2B Procurement

The global market for Aluminized PET film is vast, but quality consistency varies significantly between manufacturers. Selecting the wrong partner can lead to catastrophic issues like batch-to-batch color variance, lamination failure, or food safety recalls. To ensure a stable supply chain, use the following criteria to evaluate your potential partner.

1. In-House Laboratory & Testing Capabilities

A reliable supplier does not rely on “visual checks.” They must possess an in-house laboratory equipped to test critical parameters before every shipment. Ask your supplier for proof of the following tests:

- OTR & WVTR Testing: To verify the actual oxygen and moisture barrier performance.

- Surface Tension (Dyne) Testing: To ensure the film is ready for your printing or lamination line.

- Peel Strength Testing: To verify the bond between the aluminum layer and the PET base.

2. Consistency Across Large Batches

The biggest challenge in film production is not making one good roll, but making 1,000 rolls with identical properties.

- Vacuum Control: Does the supplier use automated closed-loop systems to monitor aluminum thickness (Optical Density) in real-time?

- Width Uniformity: Can they guarantee consistent performance from the center to the edges of wide-web rolls?

3. Technical Support & Customization

A “trader” sells you what is in stock; a “partner” engineers what you need. A reliable supplier should be able to:

- Recommend Specific Structures: Such as the 6 core structures we discussed (e.g., VMPET+PE vs. PET+AL+PE).

- Adjust Specifications: Tailoring the Dyne level or Optical Density to match your specific machinery or ink system.

4. Certification & Compliance Transparency

Don’t just take their word for it. Ensure they can provide up-to-date, verifiable copies of:

- Food Safety: FDA, EC 10/2011, and BRCGS.

- Quality Management: ISO 9001:2015.

- Traceability: Every roll should have a unique batch ID linked to its raw material origins.

5. Logistics & Packaging Protection

Aluminized film is sensitive to moisture and physical impact. A professional supplier will use:

- Suspended Packaging: Preventing the film surface from touching the pallet to avoid pressure marks.

- Moisture Barriers: Multiple layers of wrap and desiccant to prevent aluminum oxidation during sea freight.

Chapter 8: Common Mistakes When Purchasing Aluminized Polyester Film

Avoiding Costly Errors in Material Selection and Logistics

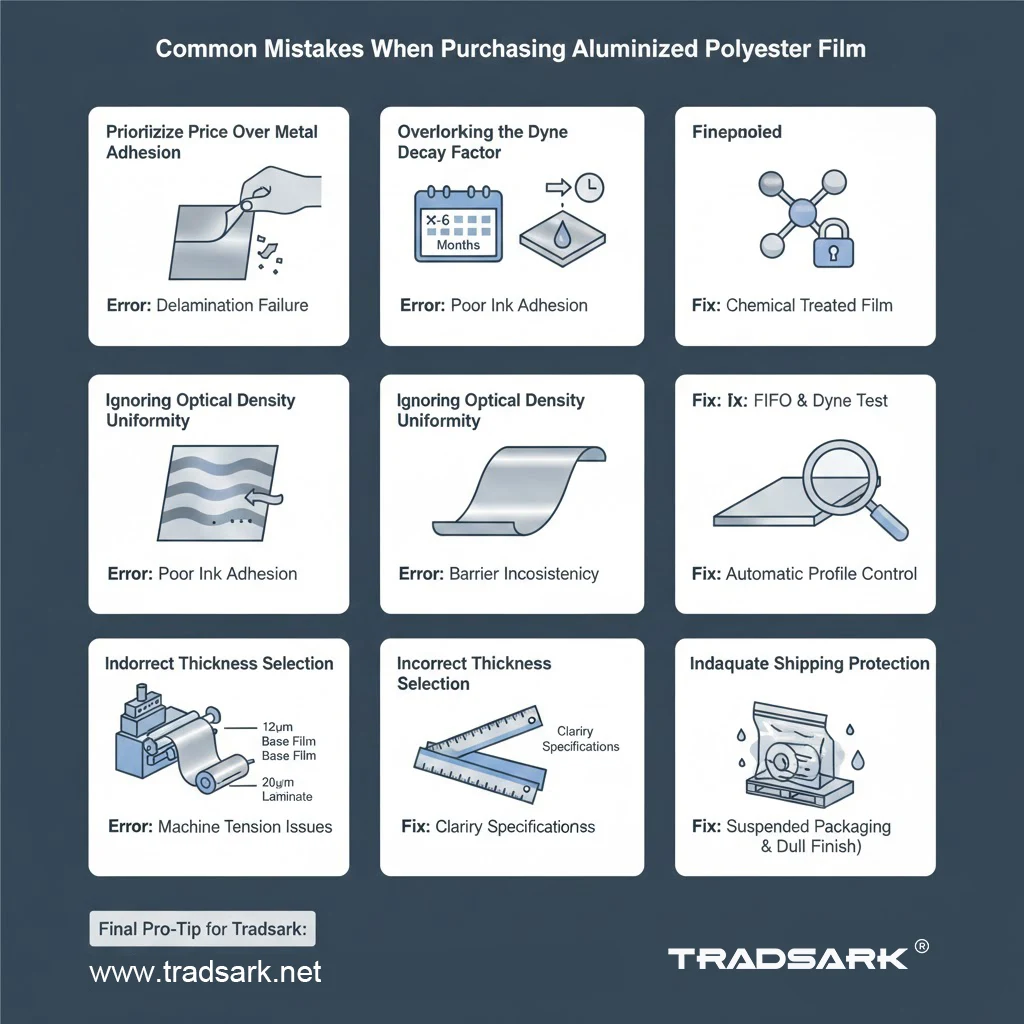

Even experienced procurement teams can make mistakes when sourcing Aluminized PET (Met PET) film. Because this material is technically sensitive, a small oversight in specifications can lead to entire batches of wasted product. Below are the most frequent pitfalls and how to avoid them.

1. Prioritizing Price Over “Metal Adhesion”

The most common mistake is choosing the lowest-priced film without verifying the bond strength between the aluminum and the PET.

- The Error: Purchasing a standard corona-treated film for a high-humidity application.

- The Result: The aluminum layer “transfers” or peels off during lamination, causing the package to fail.

- The Fix: For liquid packaging or harsh environments, always specify Chemical Treated (Primer) or Plasma Treated films to ensure permanent metal adhesion.

2. Overlooking the “Dyne Decay” Factor

Purchasing managers often buy large quantities to save on costs, forgetting that surface treatment has a shelf life.

- The Error: Storing corona-treated film for more than 3–6 months.

- The Result: The Dyne level (surface tension) naturally drops over time. When you finally move the film to the printing press, the ink won’t stick, leading to “crawling” or smearing.

- The Fix: Practice “First-In, First-Out” (FIFO) inventory management and test the Dyne level with a test pen before starting any new production run.

3. Ignoring Optical Density (OD) Uniformity

Buyers often check the average OD but ignore the uniformity across the roll.

- The Error: Accepting film with “streaks” or “clouds” in the metallic finish.

- The Result: These visual inconsistencies are often signs of microscopic pinholes. This causes the OTR (Oxygen Transmission Rate) to fluctuate, leading to some bags in a batch spoiling faster than others.

- The Fix: Ensure your supplier uses an Automatic Profile Control system during the vacuum deposition process.

4. Incorrect Thickness Selection (Base vs. Total)

Confusion between the base PET thickness and the final laminate thickness can lead to machine jams.

- The Error: Ordering 12μm film when the machine was calibrated for a 20μm laminate, or vice versa.

- The Result: Tension issues on the FFS (Form-Fill-Seal) machine, leading to wrinkles or poor heat seals.

- The Fix: Always clarify whether you are discussing the Base Film thickness or the Total Composite thickness of the multi-layer structure.

5. Inadequate Shipping Protection

Aluminized film is highly susceptible to oxidation if exposed to moisture during sea freight.

- The Error: Using standard pallet wrapping for long-distance international shipping.

- The Result: The film arrives with a “dull” or white-ish tint instead of a mirror finish, signaling that the aluminum has oxidized and lost its barrier properties.

- The Fix: Insist on Suspended Packaging with desiccants and moisture-barrier vacuum bags for all overseas shipments.

Chapter 9: Have Technical Questions or Need Custom Specifications?

Choosing the right aluminized film is a balance of science and strategy. If you are facing challenges with metal adhesion, dyne level decay, or barrier performance, TRADSARK’s engineering team is here to help.

We don’t just provide quotes; we provide solutions. Whether you need a customized structure for a unique application or a technical audit of your current packaging, feel free to reach out to us. Let’s build a more secure packaging foundation together.

TRADSARK YOUR TRUSTED FILM SOLUTION PARTNER.

- 📧 Consult our Technical Team: tradsark@gmail.com

- 💬 WhatsApp: +86 190 0646 0458