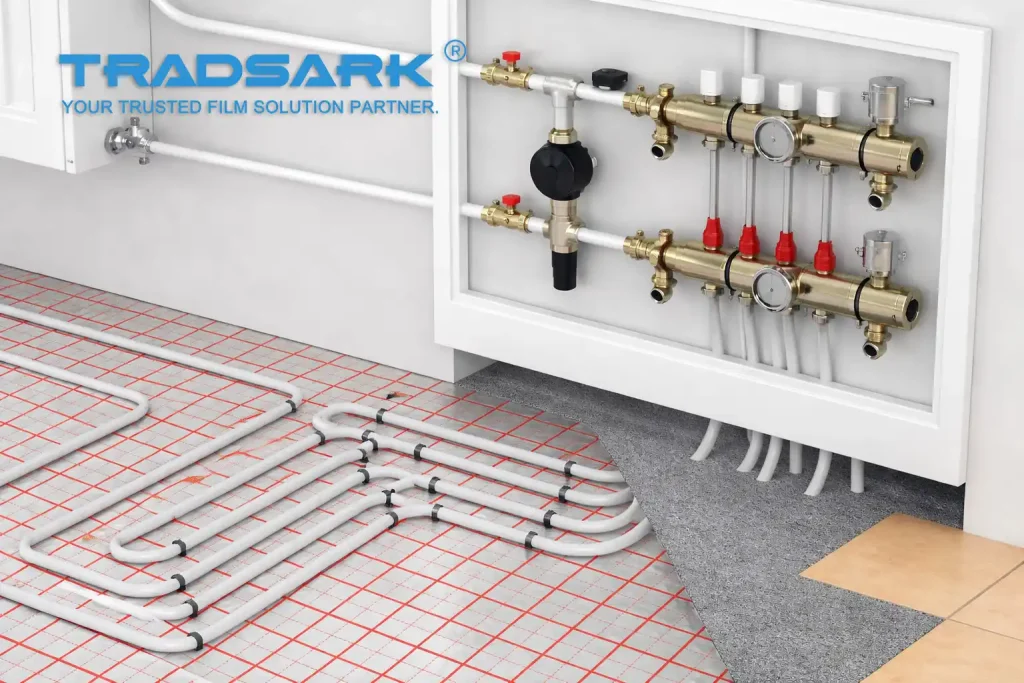

As a premier 5-Layer Underfloor Heating Insulation Membrane manufacturer, Tradsark is dedicated to engineering high-performance, reliable solutions for modern radiant floor heating systems. The core principle of any efficient hydronic or electric underfloor heating (UFH) installation lies beneath the pipes or cables—in the insulation membrane. This critical component prevents downward heat loss, directs thermal energy upwards into the living space, and ensures system responsiveness and energy efficiency. Tradsark specializes in advanced 5-layer composite membranes, which represent the pinnacle of insulation technology for the Chinese and global markets.

This comprehensive guide delves into the technical specifications, distinct advantages, and appropriate applications of the three primary 5-layer membrane structures prevalent in China’s construction industry. Tradsark excels in manufacturing all three, providing tailored solutions for diverse project requirements, from residential refurbishments to large-scale commercial builds.

The Science and Importance of 5-Layer Underfloor Heating Insulation

Before exploring the specific structures, it’s crucial to understand why a 5-layer design is considered superior and what role each layer plays in the system’s overall performance.

The Problem: Downward Heat Loss

Without proper insulation, a significant portion of the heat generated by an underfloor heating system—up to 30% or more—can be lost downwards into the subfloor. This waste translates directly into higher energy bills, longer system warm-up times, and reduced comfort. The insulation membrane’s primary job is to create a thermal barrier that mitigates this loss.

The 5-Layer Solution: Synergy in Composite Materials

A single-layer material cannot optimally provide all necessary functions: moisture resistance, durability, thermal reflection, and secure adhesion. The 5-layer laminate structure combines specialized materials, each with a dedicated role, to create a product where the whole is greater than the sum of its parts.

- Protective Outer Layers: These provide mechanical strength, puncture resistance, and a barrier against moisture and concrete alkalinity.

- Adhesive Layers: High-performance bonding agents ensure the layers are permanently laminated, preventing delamination—a common failure point in inferior products.

- Aluminum Foil Core: This is the heart of the membrane. It acts as a radiant heat reflector, directing over 95% of the infrared radiation upwards. It also often serves as a grounding layer for electric UFH systems.

Why Tradsark’s Manufacturing Precision Matters

As a manufacturer, Tradsark controls the entire production process, from sourcing raw materials to lamination. This allows for strict quality control over:

- Aluminum Foil Purity and Thickness: Ensuring consistent, high reflectivity (≥ 95%).

- Adhesive Formulation: Using eco-friendly, high-bond-strength adhesives that remain stable across temperature ranges.

- Lamination Integrity: Guaranteeing a bubble-free, perfectly bonded composite that will not separate under the stress of installation or concrete pour.

Deep Dive: The Three Predominant 5-Layer Membrane Structures in China

The Chinese market has standardized around three main 5-layer membrane structures, differentiated primarily by the material used for the protective outer layers. Tradsark manufactures all three, offering specifiers and installers the flexibility to choose the optimal product for their specific application.

Structure 1: The BOPP-Based Universal Performer

This structure represents a robust and highly cost-effective solution, widely used in residential and commercial projects.

Layer-by-Layer Breakdown:

- Layer 1 (Outermost): BOPP Protective Layer. Biaxially Oriented Polypropylene provides a tough, moisture-proof first line of defense.

- Layer 2: Eco-Friendly Adhesive Layer. Bonds the BOPP to the aluminum core.

- Layer 3: Aluminum Foil (Thermal Reflection Core). Typically 7-9 microns, with a reflectivity of ≥ 95%.

- Layer 4: Eco-Friendly Adhesive Layer (Symmetric Bonding). Mirrors Layer 2 for balanced construction.

- Layer 5 (Innermost): BOPP Protective Layer. Completes the symmetric, durable encapsulation of the foil.

Tradsark Technical Parameters & Specifications:

- Total Thickness: 0.3mm – 0.5mm

- Aluminum Foil Thickness: 7μm (standard), 9μm (premium)

- Thermal Reflectivity: ≥ 95%

- Water Vapor Barrier: Excellent (BOPP is inherently hydrophobic)

- Tensile Strength (Machine Direction): ≥ 50 N/cm

- Puncture Resistance: High

- Operating Temperature Range: -20°C to +80°C

- Standard Roll Sizes: 1m x 50m, 1.5m x 50m

Advantages of the BOPP Structure:

- Excellent Moisture Barrier: BOPP has virtually zero water absorption, making it ideal for ground-floor slabs or areas with potential dampness.

- High Chemical Resistance: Highly resistant to alkalis in concrete screeds, acids, and salts.

- Good Puncture & Tear Resistance: Withstands typical construction site traffic.

- Cost-Effectiveness: Offers a superb balance of performance and price.

- Lightweight and Easy to Handle: Simplifies installation.

Ideal Application Scenarios:

- New-build residential concrete slab installations.

- Commercial ground-floor applications.

- Environments where moisture resistance is a priority.

- Projects requiring a reliable, budget-conscious premium insulation.

Structure 2: The PET-Based High-Strength Specialist

This structure utilizes PET (Polyethylene Terephthalate) for enhanced mechanical properties, making it a favorite for demanding installations.

Layer-by-Layer Breakdown:

- Layer 1 (Outermost): PET Protective Layer. Offers superior tensile strength and stiffness.

- Layer 2: Eco-Friendly Adhesive Layer.

- Layer 3: Aluminum Foil (Thermal Reflection Core).

- Layer 4: Eco-Friendly Adhesive Layer (Symmetric Bonding).

- Layer 5 (Innermost): PET Protective Layer.

Tradsark Technical Parameters & Specifications:

- Total Thickness: 0.4mm – 0.6mm

- Aluminum Foil Thickness: 9μm (standard), 12μm (optional)

- Thermal Reflectivity: ≥ 97%

- Water Vapor Barrier: Very Good

- Tensile Strength (Machine Direction): ≥ 80 N/cm (significantly higher than BOPP)

- Puncture Resistance: Very High

- Dimensional Stability: Exceptional; low thermal shrinkage/expansion.

- Operating Temperature Range: -40°C to +120°C

Advantages of the PET Structure:

- Exceptional Tensile Strength and Stiffness: Can span minor subfloor cracks without tearing and provides a very stable base for pipe/tile fixing.

- Superior Durability: Best resistance to prolonged construction phase abuse.

- Higher Temperature Tolerance: Suitable for systems with potential local overheating or higher flow temperatures.

- Excellent Dimensional Stability: Won’t slacken or shrink after installation.

Ideal Application Scenarios:

- Large-area commercial and industrial UFH projects.

- Installations over substrates with minor cracking or imperfection.

- Projects with extended construction timelines where the membrane must endure heavy traffic.

- Systems where maximum mechanical robustness is the primary concern.

Structure 3: The PET/PE Hybrid: The Ultimate Bonding Solution

This asymmetric structure combines the best of both PET and PE (Polyethylene) to create a membrane optimized for scenarios requiring an exceptional bonding surface for screeds or leveling compounds.

Layer-by-Layer Breakdown:

- Layer 1 (Outermost): PET Protective Layer. Provides the strong, durable top surface.

- Layer 2: Eco-Friendly Adhesive Layer.

- Layer 3: Aluminum Foil (Thermal Reflection Core).

- Layer 4: Eco-Friendly Adhesive Layer (Symmetric Bonding).

- Layer 5 (Innermost): PE Protective Layer. Creates a unique, optimally bonded interface with the screed.

Tradsark Technical Parameters & Specifications:

- Total Thickness: 0.35mm – 0.55mm

- Aluminum Foil Thickness: 9μm

- Thermal Reflectivity: ≥ 96%

- Bond Strength with Screed: Excellent (PE layer promotes mechanical and chemical adhesion)

- Tensile Strength (Machine Direction): ≥ 70 N/cm (strong PET side)

- Puncture Resistance: High on PET side, good on PE side.

- Operating Temperature Range: -30°C to +100°C

Advantages of the PET/PE Hybrid Structure:

- Unparalleled Screed Adhesion: The PE layer forms a superior bond with cementitious screeds, virtually eliminating the risk of delamination between the membrane and the screed—a critical factor for tile integrity.

- Dual-Surface Functionality: The tough PET top side handles installation loads, while the PE bottom side manages bonding.

- Crack Bridging: The strong PET face helps bridge hairline cracks, while the flexible PE layer accommodates minor movement.

- Optimized for Thin-Screed & Tile Applications: The secure bond is crucial for avoiding hollow tiles in finished floors.

Ideal Application Scenarios:

- Thin-screed or self-leveling compound applications.

- All types of tiled floor finishes (ceramic, porcelain, stone).

- Refurbishment projects where perfect screed adhesion is non-negotiable.

- Floating floor constructions requiring a guaranteed monolithic bond.

Comparative Analysis: Choosing the Right Tradsark Membrane

| Feature | Structure 1: BOPP/BOPP | Structure 2: PET/PET | Structure 3: PET/PE |

|---|---|---|---|

| Primary Characteristic | Cost-Effective Moisture Barrier | High-Strength & Durable | Superior Screed Adhesion |

| Top/Bottom Layers | BOPP / BOPP | PET / PET | PET / PE |

| Key Strength | Moisture & Chemical Resistance | Tensile Strength & Puncture Resistance | Bond Strength with Cementitious Materials |

| Ideal For | Standard slabs, moisture-prone areas | Demanding sites, large commercial floors | Tiled floors, thin screeds, critical bonding |

How to Select with Tradsark:

- Assess the Subfloor: Is it a dry, stable slab (all options) or a potentially damp base (prioritize BOPP/BOPP)?

- Consider Installation Conditions: Will the membrane face heavy traffic for weeks (choose PET/PET)?

- Define the Floor Build-Up: Is it a standard 65mm+ screed (all options) or a thin, sub-40mm screed (prioritize PET/PE for bond)?

- Determine the Final Flooring: Tiles or stone (PET/PE is optimal) vs. engineered wood or vinyl (BOPP/BOPP or PET/PET are suitable).

Tradsark: Engineering Excellence in Thermal Insulation

As a forward-thinking manufacturer, Tradsark doesn’t just produce these three standards; we innovate around them. Our commitment includes:

- R&D Investment: Continuously testing adhesive formulations and layer composites for even better performance and environmental profiles.

- Customization: Ability to adjust parameters like foil thickness, total roll width, and length for large OEM projects.

- Quality Assurance: Every batch undergoes rigorous testing for reflectivity, tensile strength, laminate integrity, and water barrier properties.

- Sustainability: Our “Eco-Friendly Adhesive Layers” are formulated with low VOC content and are compliant with international environmental and indoor air quality standards.

Installation Best Practices with Tradsark Membranes

No matter the structure, correct installation is key:

- Subfloor Preparation: Ensure it is clean, dry, and level.

- Correct Side Up: For PET/PE membranes, the PE side must face down towards the subfloor. Symmetric membranes (BOPP/BOPP, PET/PET) can be installed either side up.

- Seaming: Use high-quality aluminum foil tape to seal all seams and edges, creating a continuous vapor barrier and reflective plane.

- Perimeter Insulation: Always combine with vertical perimeter insulation strips to isolate the heated slab from cold walls.

Conclusion

The choice of underfloor heating insulation membrane is a critical technical decision that impacts long-term energy efficiency, comfort, and system reliability. The Chinese market’s three dominant 5-layer structures—BOPP-based, PET-based, and the PET/PE hybrid—each offer distinct advantages tailored to different project needs.

As a leading 5-Layer Underfloor Heating Insulation Membrane manufacturer, Tradsark provides the full spectrum of these high-quality solutions. Our in-depth understanding of material science, composite lamination, and real-world application challenges ensures that specifiers, contractors, and end-users receive a product that delivers on its promises. Whether your project demands the moisture resistance of BOPP, the supreme strength of PET, or the unparalleled bond of the PET/PE hybrid, Tradsark has the engineered solution to form the perfect foundation for an efficient and responsive underfloor heating system.

Choose Tradsark – where every layer is engineered for performance.